Wind Turbine Foundation Anchors Accessories

PVC Sleeve

| Designation | Outer Diameter |

Inner Diameter |

Specification |

|---|---|---|---|

| 1” | 1.3” (33 mm) |

1.17” (30 mm) |

Class 200 |

| 1-1/4” | 1.7” (42 mm) |

1.5” (38 mm) |

Class 200 |

| 1-1/2” | 1.9” (48 mm) |

1.7” (43 mm) |

Class 200 |

| 2” | 2.4” (61 mm) |

2.1” (52 mm) |

Schedule 40 |

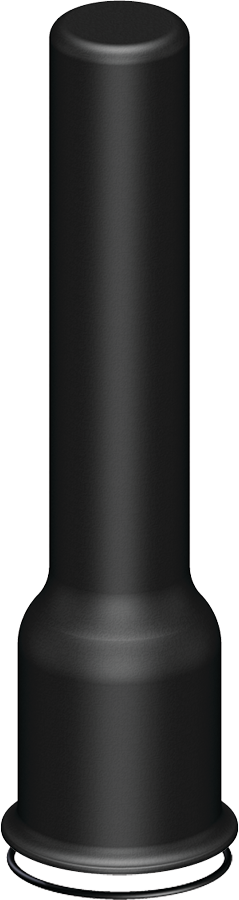

R79T Tower End Cap

The Williams Tower End Cap was designed to protect the foundation anchor bolts from harsh weather conditions. This resilient cap is made from high impact resistant polypropylene withUV inhibitors and attaches to the bolt for a great fit. The caps include a rubber o-ring to positively seal the cap against the tower flange, and can accommodate up to 3 extra thick hardened washers if needed.

Williams Tower End caps are for protection of the tower foundation anchor bolts. With application ofsufficient corrosion protective compound and proper installation, these caps will protect the foundationanchor bolt protrusion above the tower base from corrosion. However, these caps are not warrantedagainst damage caused by falling sheet ice, extraordinary occurrence such as, but not limited to fire,improper installation methods, or destructive actions by humans or animals

For proper installation, Williams recommends pushing the cap fully onto the anchor bolt, followed by turning in the direction of the threads to completely engage. Also recommended is the application of grease or some other corrosion inhibiting compound to the bolt prior to cap installation.

| Maximum Anchor Bolt Projection |

Anchor Bolt Type |

Part Number |

|---|---|---|

| 13” (330 mm) |

#10 & #11 Grade 75 Rebar #11 Grade 90 Rebar 1-1/4” & 1-3/8” 150 KSI Bar M36 – M42 Bolts |

R79T2413 |

| 15” (381 mm) |

R79T2615 | |

| 16” (406 mm) |

#14 Grade 75 Rebar 1-3/4” 150 KSI Bar |

R79T3216 |

Ultra-Bond Epoxy

Williams recommends Ultra-Bond Epoxy as an excellent choice when a high strength, fast setting adhesive is necessary. It is a two component (1:1ratio) high modulus structural epoxy gel that provides maximum field reliability in a wide temperature (35 to 115 degree F) range with a minimum cure time.Talk to a Williams technical representative for more details concerning its use on wind turbine foundations

Williams Wind Foundation Non-Shrink Grout

A high flow, high strength grout ideal for grouting wind tower founda-tions. Conforming to ASTM C-1107 with an ultimate average strength of12,000 psi in 28 days and quick set times in temperatures as low as 35°F.

Williams Wind Foundation Epoxy Grout

A high performance, precision flowable epoxy grout engineered to meet the needs of the wind construction industry. Williams Wind FoundationEpoxy grout is an ideal product choice for turbine foundation grout pads when the schedule demands a quick turn around time. Average 24 hour strengths of 12.000 PSI and ultimate strengths up to 16,000 PSI means faster tower erection, quicker torque down time for foundation anchor bolts, greater dynamic loading, vibration dampening and reduced maintenance costs.

Chemicals

Williams distributes a full line of environmentally friendly construction chemicals, from VOC compliant high performance concrete sealers and curing compounds to biodegradable form-releases and evaporation retarders. All products are designed and supplied to meet today’s job site environmental standards