Micropiles

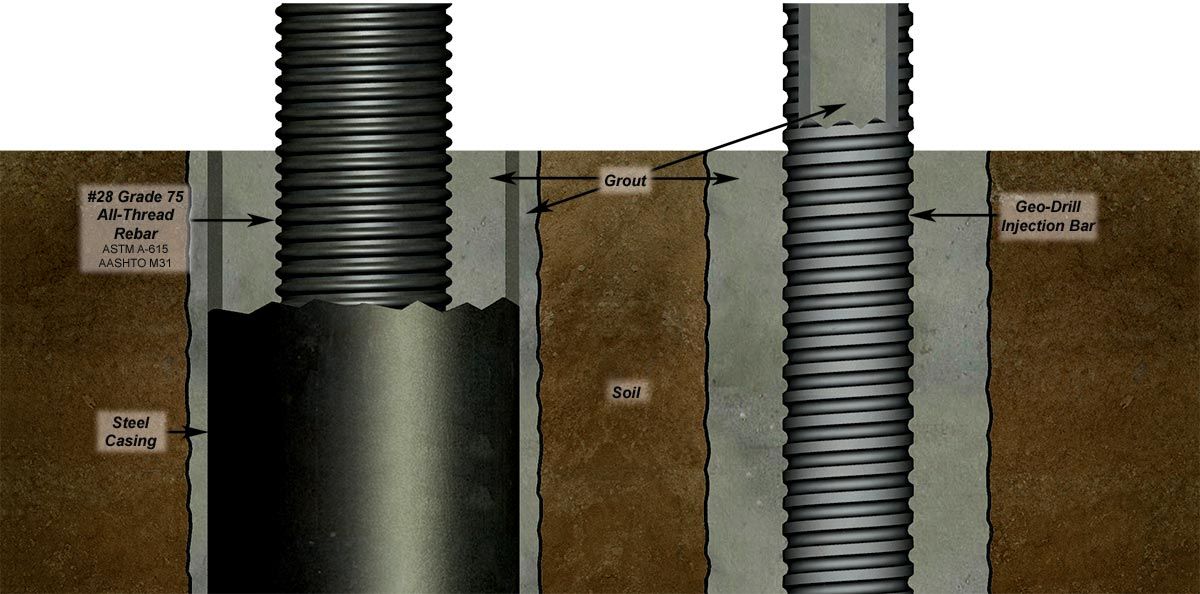

Micropiles are high capacity, small diameter (5” to 12”) drilled and grouted in-place piles designed with steel reinforcement to primarily resist structural loading. Micropiles have rapidly gained popularity for foundations in urbanized areas or in locations with low headroom and restricted access. They are an ideal choice for underpinning or emergency repairs because they can be installed in virtually any ground condition with minimal vibration and disturbance to existing structures. Williams larger diameters of All-Thread Rebar are popular choices for micropile reinforcement.

Williams offers right-hand threaded Grade 75 & Grade 80 All-Thread Rebar in #14 – #32 along with a selection of reducer couplers that can adapt to splice together any larger size bar to any smaller size. Williams also offers Grade 90 All-Thread-Rebar and 150 KSI All-Thread-Bar as alternatives for micropile design applications upon request.

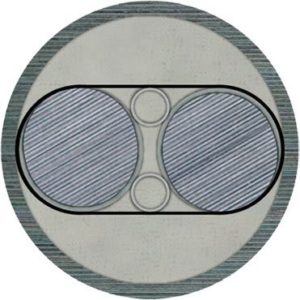

Larger Bar Micropile Cost Saving Advantages

In larger micropile designs, casing diameter is minimized because the effective net area available for reinforcement is optimized with a single larger bar versus smaller bundled bars (see example). There is also an increased rate of production installing a single larger bar versus smaller bundled bars.

Cross Section Area

9.61 in²

(6,200 mm²)

Cross Section Area

9.82 in²

(6,336 mm²)

Hollow Bar Micropiles

Accepted by the FHWA in the Micropile Design and Construction Guidelines Manual, Hollow Bars are being used increasingly for micropile applications. Through the increased bond stress resultant from the simultaneous drilling and grouting operation, Hollow Bars are the reinforcement bar choice in collapsing soil conditions.

Using sizes from 32 mm to 130 mm, these Hollow Bars offer up to 1785 kips of strength, up to 16.2 in² of cross sectional reinforcement area, and their section modulus provides considerable bending resistance. A variety of drill bits promise efficient installation and Williams offers a full line of adaptation equipment and rental grout plants necessary for Hollow Bar anchor installation.

Single Bar Micropile System

Multi-Bar Micropiles

Multi-bar elements are often used for attaining ultra-high load carrying capacity in micropiles. High-rise office buildings and high-rise condominiums are examples where such high load carrying micropiles (or sometimes referred to as mini-caissons) are used. Each multi-bar micropile project is uniquely designed by Williams to specific contractor specifications and shipped to the jobsite fabricated in durable cages for quick installation. Williams stands alone in being a customized manufacturer and therefore offers the advantage to the industry of niche accessories to optimize efficiency and costs.

Micropile Testing

Micropiles are often tested in compression and tension for verification and proof tests. Micropiles are more frequently designed to resist large lateral loads, therefore, it is necessary to perform pre-production lateral load tests on single piles or groups of piles as well. Williams manufactures all products necessary for the reaction piles and offers a full line of testing equipment. Compression testing is accomplished by reacting against the bottom of a test beam that is anchored to the ground with reaction piles. The reaction piles are installed from the test pile at a minimum distance, so the reaction piles do not influence the loading of the test pile. On a typical compression test, the reaction beam is cribbed a distance off of the ground to accommodate the test jack and load cell between the test pile and the bottom of the test beam. The compressive load is then applied to the pile through the test jack reacting against the bottom of the beam. The prestress force on the reaction piles keep the beam from rolling.