S5Z WIL-X CEMENT GROUT

Conforms to ASTM C845 Type K

Wil-X is chemically compensated for shrinkage. It has a high bond value and is crack resistant for permanent installations. Wil-X can be used safely with most concrete admixtures. Wil-X grout will be thicker than a Portland cement grout with the same water to cement ratio. Therefore, use of a high-range water reducing admixture (super plasticizer) is recommended if grout will be pumped or if higher fluidity is desired. Because it is a cement-based grout, it is non-explosive and has a six-month shelf life when stored properly in a dry location and out of direct sunlight.

Compressive Strength

Wil-X Cement Grout & Water

(74° F Dry Environment)

0.44 w/c ratio

| Time | PSI | MPa |

|---|---|---|

| 1 Day | 2,800 | 19.3 |

| 3 Days | 6,400 | 44.1 |

| 7 Days | 7,700 | 53.1 |

| 28 Days | 9,500 | 65.5 |

Wil-X may be used to build up leveling pads by simply mixing with sand or pea gravel. This mixture should not be run through the grout pump.

Setting Time: Gilmore Needles (ASTM C266). Initial set 45 minutes; final set 10 hours.

Comparative compressive strength test in PSI (modified ASTM C109) Actual strengths as mixed according to Williams Instructions range from 6,000 to 9,500 PSI depending on water content. Copy of ASTM Modification available upon request.

Note: Results based on a controlled laboratory environment (see product data for details). Jobsite results may vary.

US Spec RA Grout

Product Description

Product Description

US Spec RA Grout consists of specialty blended cements and admixtures to provide maximum flow, shrinkage compensation and extended working times in an aggregate free formulation where clearances are minimal. RA Grout is non-metallic and non-corrosive. RA Grout has been specifically formulated to meet and exceed the testing requirements of ASTM C1107 and US Army Corps of Engineers CRD C-621. When tested in accordance with ASTM C827 RA Grout yields a controlled positive expansion.

Advantages

- Pumpable fluid grout for very tight clearances

- Non-bleeding

- Attains high compressive strengths at specified w/c ratios

- Extended working time for maximum pumping range

- Non-shrink from time of placement

- Thixotropic: High flow restored by agitation

- Encapsulates tendons, bolts or bars to protect from corrosion

- Consistent: Strict Quality Control testing and standards

| Time | PSI | MPa |

|---|---|---|

| 1 Day | 4,500 | 31.02 |

| 7 Days | 9,000 | 62.05 |

| 28 Days | 12,000 | 82.73 |

Packaging and Yield

US Spec RA Grout is packaged in heavy duty, polyethylene line backs containing 50 lbs (22.7 kg), yielding 0.53 cubic feet when 7.75 quarts of mixing water is used. Each pallet contains 48 bags of RA Grout.

Mixing

Mix US Spec RA Grout to a uniform consistency in accordance with the manufacturer’s instructions. Potable water containing no chlorides or other foreign substance shall be used. The water shall be accurately measured and placed in the mixer first. Start with 1.94 gallons of water per 50 lbs bag of US Spec RA Grout and mix continuously for 3-5 minutes before placing. If possible, the grout should be mixed continuously until placing is completed, but if this is not practical, a brief remixing prior to pumping or placement is adequate to overcome the effect of “thixotropic set”. Do not use any other admixtures or additives.

Note: Results based on a controlled laboratory environment (see product data for details). Jobsite results may vary.

T3P Heavy Duty Plastic Grout Tube

Furnished in product lengths for the anchors or in rolls.

| OD | ID | Part No |

|---|---|---|

| 3/8” (9.5 mm) |

1/4” (6.4 mm) |

T3P03002 |

| 1/2” (13 mm) |

3/8” (9.5 mm) |

T3P04003 |

| 5/8” (16 mm) |

1/2” (13 mm) |

T3P05004 |

| 3/4” (19 mm) |

5/8” (16 mm) |

T3P06005 |

| 1” Nom. (25 mm) |

3/4” Nom. (19 mm) |

T3P06 |

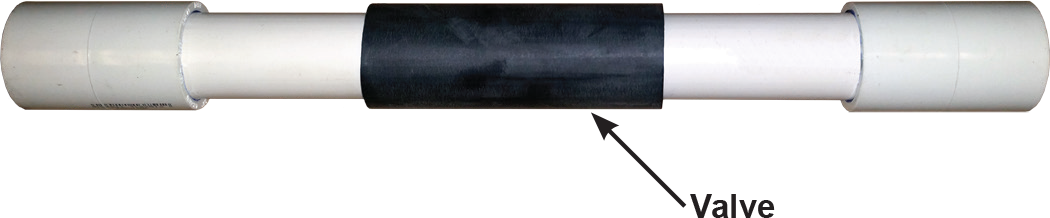

Post-Grout Tube

Williams will provide post-grout tubes for anchors bonded in weak rock or soil upon request. The Williams supplied flexible or rigid post-grout tube has a bursting strength of 1000 psi. The post-grout tube length and valve placement are adjustable and can be specified at the time of order. There is no field assembly of the post grout tube, other than attaching it to the anchor as it is being installed down the drill hole. Drill hole diameter should be a 1” minimum clearance to accommodate Post-Grout Tube.

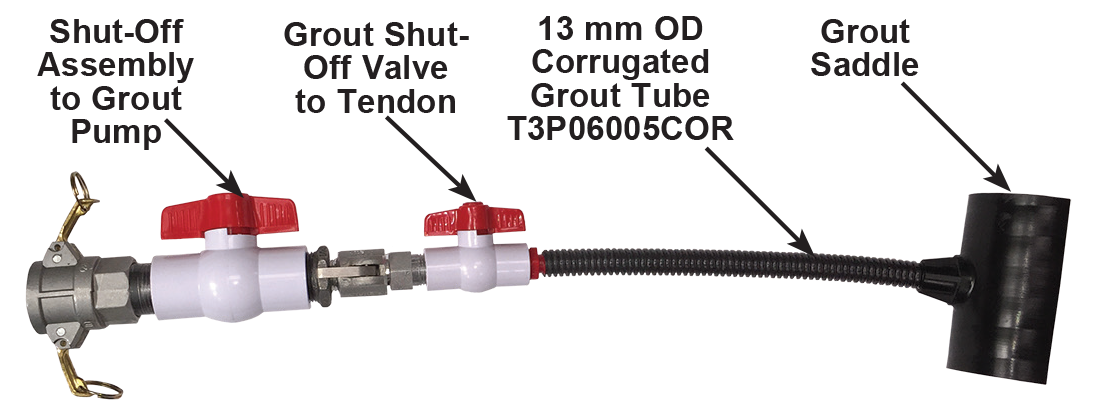

Grout Saddle with Valve

For quick attachment and release of tendons to grout hose.

T4Z Grout Tube Adapter

For down pressure grouting only when grout is forced through normal grout hole in the hollow rebar

Grout Socks

What was once considered to be an impossible anchorage is made easy with a practical solution from Williams. For difficult bonding applications such as anchors in weak coral, sandstone, highly fractured rock, underwater holes and in artesian water conditions, we place Grout Socks on our grout bonded anchors to prevent grout loss due to permeation or washing away by flowing water. The socks are individually manufactured to be a minimum of 1” larger than the drill hole diameter, allowing the sock to expand into the deformations in the drill hole wall, and in many cases providing the only means to achieve a mechanical bond. In some geotechnical conditions, designers should be aware that Grout Sock may adversely affect the bond strength between the grout and ground. Williams recommends that a testing program be implemented to determine actual bond stress values for elements installed with grout socks.

Super Plasticizer

Plasticizer is available and is used as a water reducer for ease of pumping grout through tubes at lower water to cement ratios.

Grout Pumps

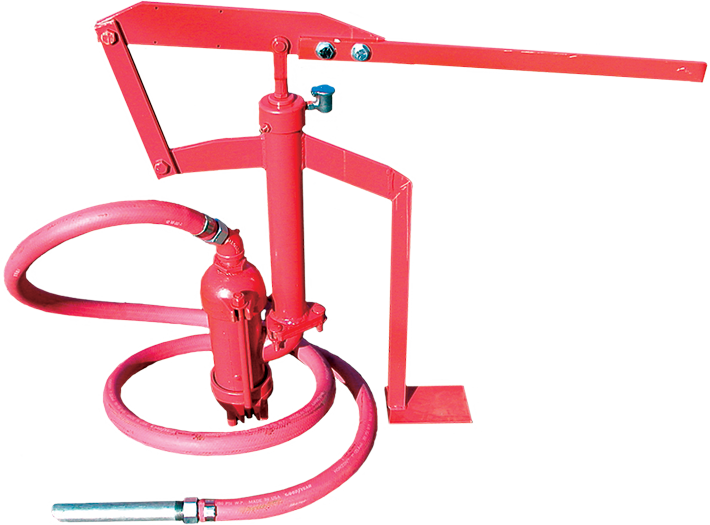

T6Z-04 Hand Pump

Use of plasticizer is recommend with hand pumps.

Pump

- Pump Type: 2 stroke, piston driven

- Output/Pressure: 40 psi average, 80 psi

Physical Specifications:

- Dimensions: 24-1/4”W x 30-3/4”H (35” w/ handle)

- Weight: 60 lbs

T6Z-08 Air Pump

Pumps cement grout only, no sand. 32 Gallon Mixing Tank. Mixes up to 2 sacks of material at once and allows for grout to be pumped during mixing or mixed without pumping.

Pump

- Output/Pressure: 8 gpm, 261 psi

Mixer

- Mix Tank: 22 Gallon

- Holding Hopper: 12 Gallon

Physical Specifications

- Dimensions: 59”L x 30”W x 51”H

- Weight: 575 lbs

Colloidal Grout Plant

Pump

- Pump Type: Progressing cavity

- Output/Pressure: Variable up to 20 gpm, 261 psi

Colloidal Mixer

- Mix Tank: 13 CF with bottom clean out

- Mixing Pump: High Shear Colloidal

- Holding Tank: 13 CF paddle agitating

Drive Power

- Air: 300 CFM, 100 psi

Physical Specifications

- Dimensions: 96”L x 60”W x 74”H

- Weight: 1,550 lbs

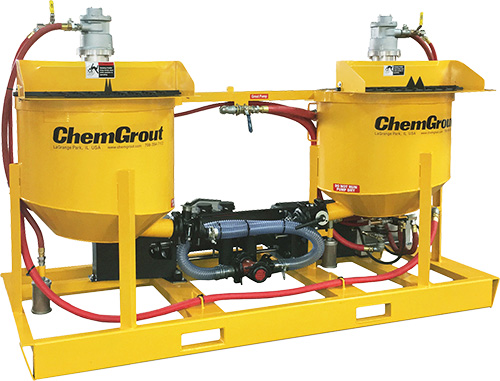

High Pressure Colloidal Grout Plant

Pump

- Pump Type: Double acting plunger pump

- Output/Pressure: 15 gpm, 2,000 psi

Colloidal Mixer

- Mix Tank: Dual 70 gallon

- Mixing Pump: High Shear Colloidal

Drive Power

- Air: 375 CFM, 100 psi

Physical Specifications

- Dimensions: 96”L x 40”W x56”H

- Weight: 1,400 lbs