Epoxy Concrete Anchors

When are Epoxy Concrete Anchors used?

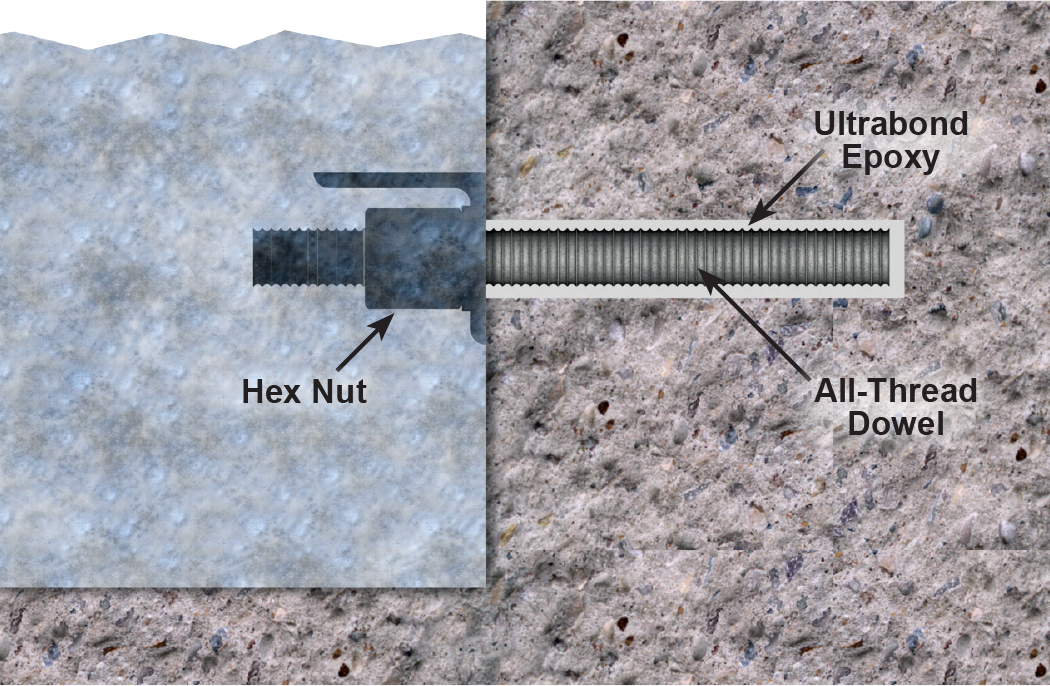

• Epoxy is ideal for passive dowels or anchors without sustained loading conditions; however, when high capacity anchors are to be prestressed, the designer should consider Williams Spin-Lock mechanical anchors.

• Use Williams epoxy anchors for concrete anchors loaded in shear.

Applications

- Concrete Foundation Repair

- Seismic Retro-Fit

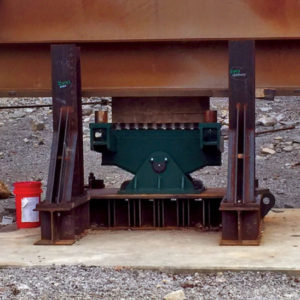

- Machinery Anchoring

- Anchors for Rail Systems

- Underwater Doweling

- Concrete Dock Repair and Construction

- Anchors subject to large shear loads

- Bridge Pier Reinforcement

- Pier Cap Repairs

- Dam Refacement

- General Plant Maintenance

- Column Anchors

- Light Poles

Ultrabond HS-1CC

Ultrabond HS-1CC is IBC/IRC code compliant (ESR 4094), nationally DOT approved or pending, and the first anchoring system for cracked and uncracked concrete that’s available in both cartridge and bulk dispensing options. With the highest short-term elevated temperature resistance of any approved epoxy, Ultrabond HS-1CC has a convenient 1:1 mix ratio for easier application. It’s also NSF61 approved and made in the USA.

Ultrabond HYB-2CC

For cracked and uncracked concrete, new Ultrabond HYB-2CC is IBC approved (ESR 4535) for application in temperatures down to 23ºF. And for jobs where a quick cure rate is required, it will cure completely in 30 minutes at 70ºF. Approved for use in dry, damp and water-filled holes, Ultrabond HYB-2CC features a higher creep resistance and a longer shelf life. When you need a high strength hybrid anchoring adhesive that’s approved for multiple anchor types – including fractional and metric threaded rod & rebar – choose Ultrabond HYB-2CC.

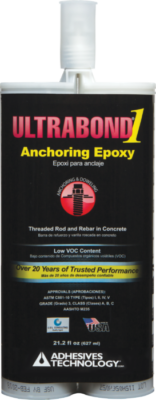

Ultrabond 1

DOT Approved – Over 20 years of trusted performance

Tried and true for more than 20 years, Ultrabond 1 is NTPEP compliant, offering substantial load capacity and a convenient 1:1 mix ratio. Made in the USA, Ultrabond 1 has numerous DOT approvals. Available in a variety of cartridge sizes and bulk containers.

Ultrabond 2

Extended working time for warmer weather

Much like Ultrabond 1 with a convenient 1:1 mix ratio and a variety of cartridge sizes and bulk containers, but with the added benefit of delayed set for extended working time.

Ultrabond Comparison

| Epoxy Type |

Strength (Scale 1-5) |

Cure Speed (Scale 1-5) |

Install Temperature |

|---|---|---|---|

| Ultrabond HS-1CC | 5 | 6 | 38-125° F |

| Ultrabond HYB-2CC | 5 | 5 | 23-104° F |

| Ultrabond 1 | 3 | 2 | 40-110° F |

| Ultrabond 2 | 2 | 1 | 40-110° F |

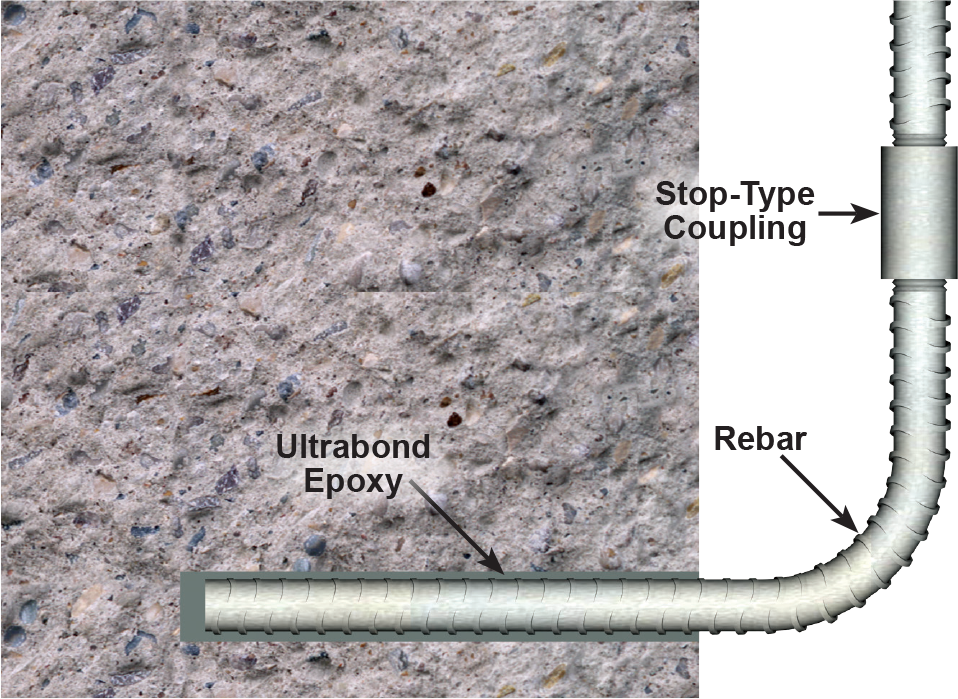

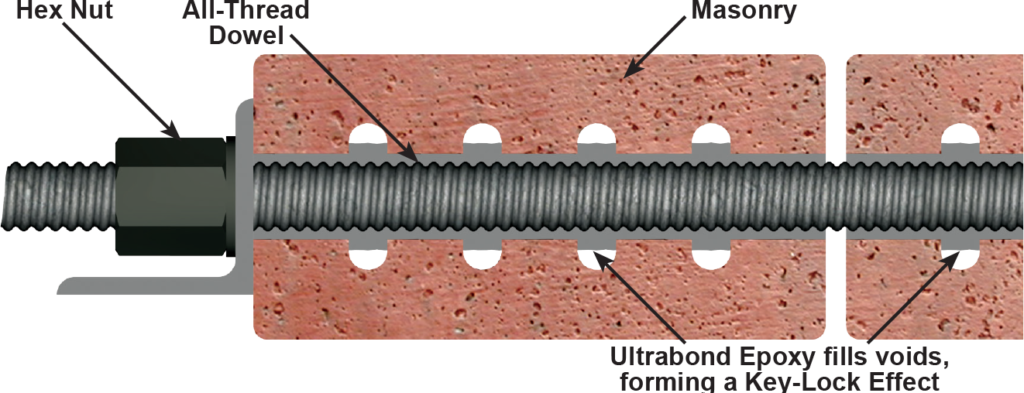

Typical Masonry Application

Rebar Extensions