Hydraulic Jacks for Threaded Bar Anchors

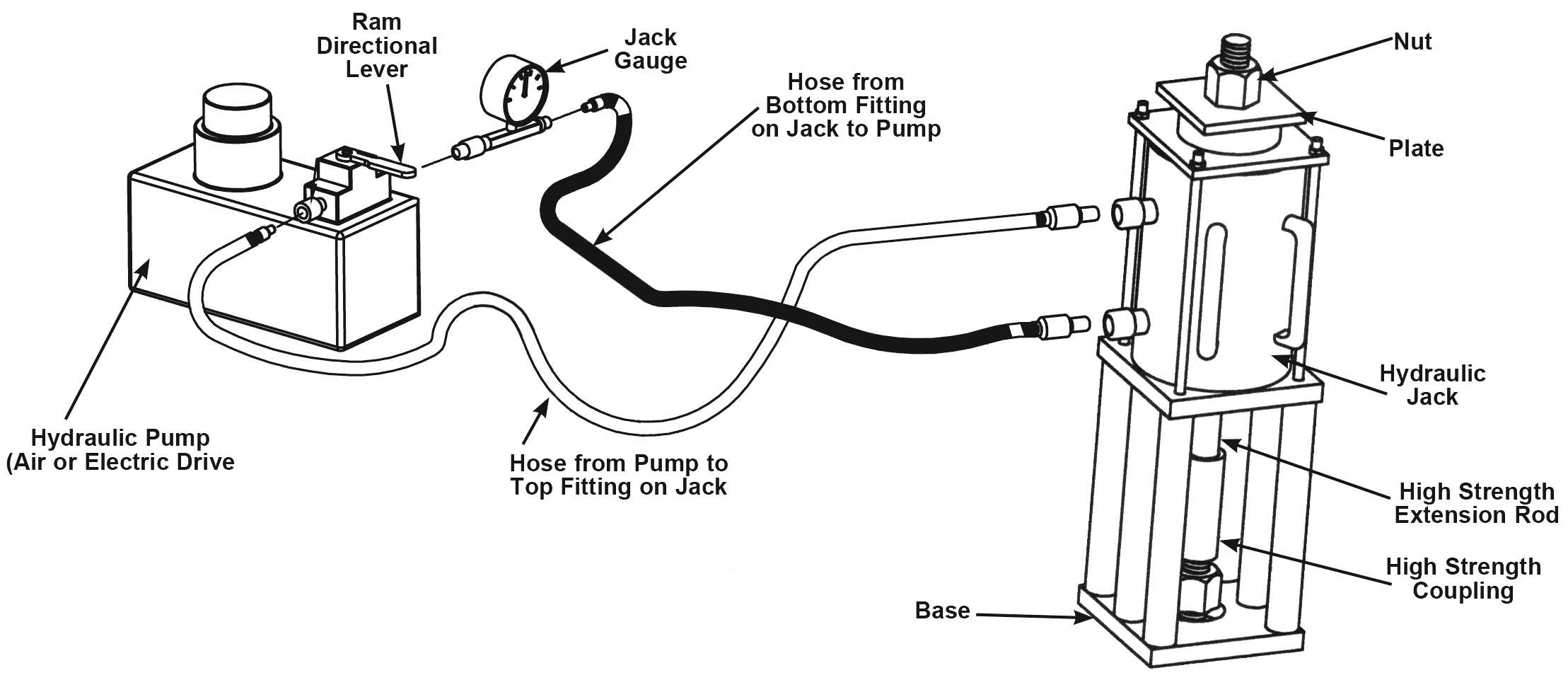

T7Z Open Frame Hydraulic Jacks

Used for testing and prestressing All-Thread-Bars. Available with up to 5-1/8” center hole. Unit comes with ram, pump, gauge, hoses, jack stand, high strength coupling, high strength test rod, plate, hex nut and knocker wrench.

| Jack Capacity |

Pump Method |

Ram Height |

Base Size |

Ram Travel |

Minimum Total Ram & Frame Height |

Maximum Test Rod Diameter |

Ram Area |

Approx. Total Ram & Frame Weight |

|---|---|---|---|---|---|---|---|---|

| 10 tons (89 kN) |

Hand Single Acting |

5-5/16” (135 mm) |

3” Diameter (76 mm) |

2-1/2” (64 mm) |

8-3/8” (213 mm) |

3/4” (19 mm) |

2.12 in2 (14 cm2) |

12 lbs (5.4 kg) |

| 30 tons (267 kN) |

Hand Double Acting |

6-1/16” (154 mm) |

8” x 8” (203 x 203 mm) |

3” (76 mm) |

19” (483 mm) |

1-1/4” (32 mm) |

5.89 in2 (38 cm2) |

80 lbs (36 kg) |

| 60 tons (534 kN) |

Hand, Air, or Electric Double Acting |

9-1/2” (241 mm) |

9” x 9” (228 x 228 mm) |

5” (127 mm) |

29” (737 mm) |

2-1/8” (54 mm) |

12.31 in2 (79 cm2) |

153 lbs (69 kg) |

| 60 tons (534 kN) |

Hand, Air, or Electric Double Acting |

12-3/4” (324 mm) |

9” x 9” (228 x 228 mm) |

6-1/2” (165 mm) |

32-1/4” (737 mm) |

2-1/8” (54 mm) |

12.73 in2 (82 cm2) |

173 lbs (78 kg) |

| 100 tons (890 kN) |

Air or Electric Double Acting |

13-1/2” (343 mm) |

9” x 9” (228 x 228 mm) |

6” (152 mm) |

29-1/8” (740 mm) |

3-1/8” (79 mm) |

20.63 in2 (133 cm2) |

198 lbs (87 kg) |

| 100 tons (890 kN) |

Air or Electric Double Acting |

12-3/8” (314 mm) |

9” x 9” (228 x 228 mm) |

6” (152 mm) |

28” (711 mm) |

2” (51 mm) |

20.03 in2 (129 cm2) |

192 lbs (87 kg) |

| 200 tons (1779 kN) |

Air or Electric Double Acting |

12-1/4” (311 mm) |

12” x 12” (305 x 305 mm) |

8” (203 mm) |

34” (864 mm) |

4-1/16” (103 mm) |

40.45 in2 (261 cm2) |

518 lbs (235 kg) |

| 200 tons (1779 kN) |

Air or Electric Double Acting |

27-1/2” (699 mm) |

12” x 12” (305 x 305 mm) |

15” (381 mm) |

49-1/4” (1250 mm) |

4” (102 mm) |

47.20 in2 (304 cm2) |

604 lbs (274 kg) |

| 300 tons (2670 kN) |

Electric Double Acting |

27-1/2” (699 mm) |

15” Dia. (381 mm) |

15” (381 mm) |

50-1/2” (1283 mm) |

5-3/8” (137 mm) |

78.5 in2 (506 cm2) |

1,400 lbs (635 kg) |

| 400 tons (3558 kN) |

Electric Double Acting |

18-3/4” (476 mm) |

15” Dia. (381 mm) |

6” (152 mm) |

45-3/4” (1162 mm) |

4-1/4” (108 mm) |

91.5 in2 (590 cm2) |

1,300 lbs (590 kg) |

T80 Post-Tension Hydraulic Jacks

With the T80 series the enclosed bearing housing contains a geared socket drive to tighten the bolt hex nut during tensioning. Test jack housing will accommodate up to a 16” deep pocket.

| Jack Capacity |

Pump Method |

Ram Height |

Gear Box |

Cylinder Diameter |

Ram Travel |

Minimum Total Ram & Frame Height |

Maximum Test Rod Diameter |

Max. 150 KSI Bar Size |

Ram Area |

Approx. Total Ram & Fram Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 100 tons (890 kN) |

Air or Electric Double Acting |

13-1/2” (343 mm) |

8.5” x 20.5” (216 x 520 mm) |

4.63” (118 mm) |

6” (152 mm) |

39” (990 mm) |

3-1/8” (79 mm) |

1-3/8” (35 mm) |

20.63 in2 (133 cm2) |

270 lbs (123 kg) |

Torque Equipment

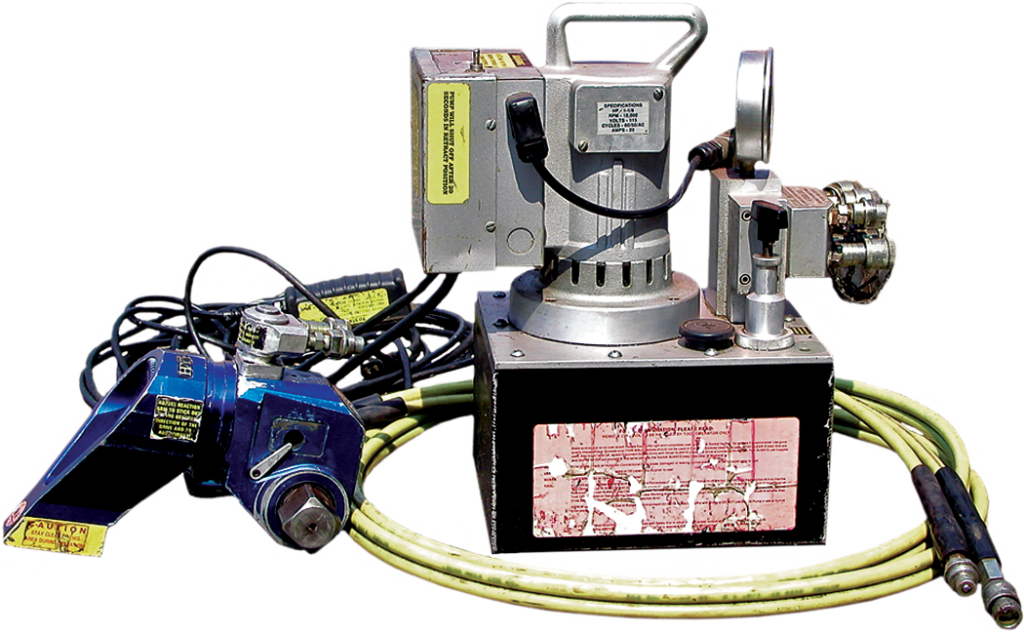

T8Z Hydraulic Torque Wrench

The hydraulic torque wrench is used for tensioning anchors in tight fitting locations where it would be difficult to use an hydraulic jack. The wrench is also recommended for use when setting the large diameter Spin-Lock anchors. The torque wrenches are light weight and can achieve a maximum of 7,400 ft-lbs. All Hydraulic Torque Wrenches have 1-1/2” square drive outputs.

| Maximum Torque |

Length | Height | Weight |

|---|---|---|---|

| 5,590 ft-lbs (773 kg/M) |

11” (279 mm) |

4.5” (114 mm) |

16.8 lbs (7.6 kg) |

| 7,400 ft-lbs (1,023 kg/M) |

10.7” (273 mm) |

7” (178 mm) |

19 lbs (11.3 kg) |

T8Z Torque Wrench

For applying torque to the anchor bolt when setting the anchor.

| Capacity (ft- lbs) |

Square Drive Size |

|---|---|

| 100-600 | 3/4” |

| 200-1,000 | 1″ |

Available with Ratchet Adapter

T8Z-04 Torque Multiplier (4:1)

For use with T8Z Torque Wrench. Other sizes available.

| Size | Square Drive Input |

Square Drive Output |

Maximum Torque |

|---|---|---|---|

| GA 186 | 1” | 1-1/2” | 4,000 (ft-lbs) |

T1Z & T2Z Long Fitting Tool Adapters

For driving hex nuts and setting tools, typically with our Spin-Lock anchor systems. Works with torque wrench or impact gun. Available with a 3/4”, 1” and 1-1/2” square drive. Please specify square drive for compatibility with your equipment.

T9F Impact Tool

Lightweight air impact guns for applying torque to anchor bolts when setting or tensioning the anchor assembly.

| Capacity (ft-lbs) |

Square Drive Size |

Size |

|---|---|---|

| 1,700 – 2,000 | 1″ | T9F-08 |

| 3,000 – 4,000 | 1/1/2″ | T9F-12 |

K3F-26 Long Fitting Wrench Adapter

Hex knocker wrenches are used for safe hex nut adjustment inside of open frame jacks.

T3Z Hex Knocker Wrench

Hex knocker wrenches are used for safe hex nut adjustment inside of open frame jacks.

Spin Adapter

This tool provides a transition between the drill steel and the setting tool when the drilling equipment is used to spin the anchor bar through the resin cartridges. Adaptations to various drill steel types are available and must be specified when placing order.

S6Z Spin-Lock Setting Tool

This tool is required for torque setting the Spin-Lock anchors or for spinning rebars into resin cartridges without jamming or scoring the bolt threads. Special two piece design allows lower hex to be held in place while upper hex is loosened for easy removal. Hardened steel allows for several reuses. Two piece design assures easy removal. Other thread forms are available for all Williams anchors.

| Bolt Rod Diameter |

Part Number |

|---|---|

| 1/2” | S6Z-OH-004 |

| 5/8” | S6Z-OH-005 |

| 3/4” | S6Z-OH-006 |

| 7/8” | S6Z-OH-007 |

| 1” | S6Z-OH-008 |

| 1-1/8” | S6Z-OH-009 |

| 1-1/4” | S6Z-OH-010 |

| 1-3/8” | S6Z-OH-011 |

| 1-1/2” | S6Z-OH-012 |

| 1-3/4” | S6Z-OH-014 |

| 1-7/8” | S6Z-OH-015 |

| 2” | S6Z-OH-016 |

R71 150 KSI All-Thread-Bar

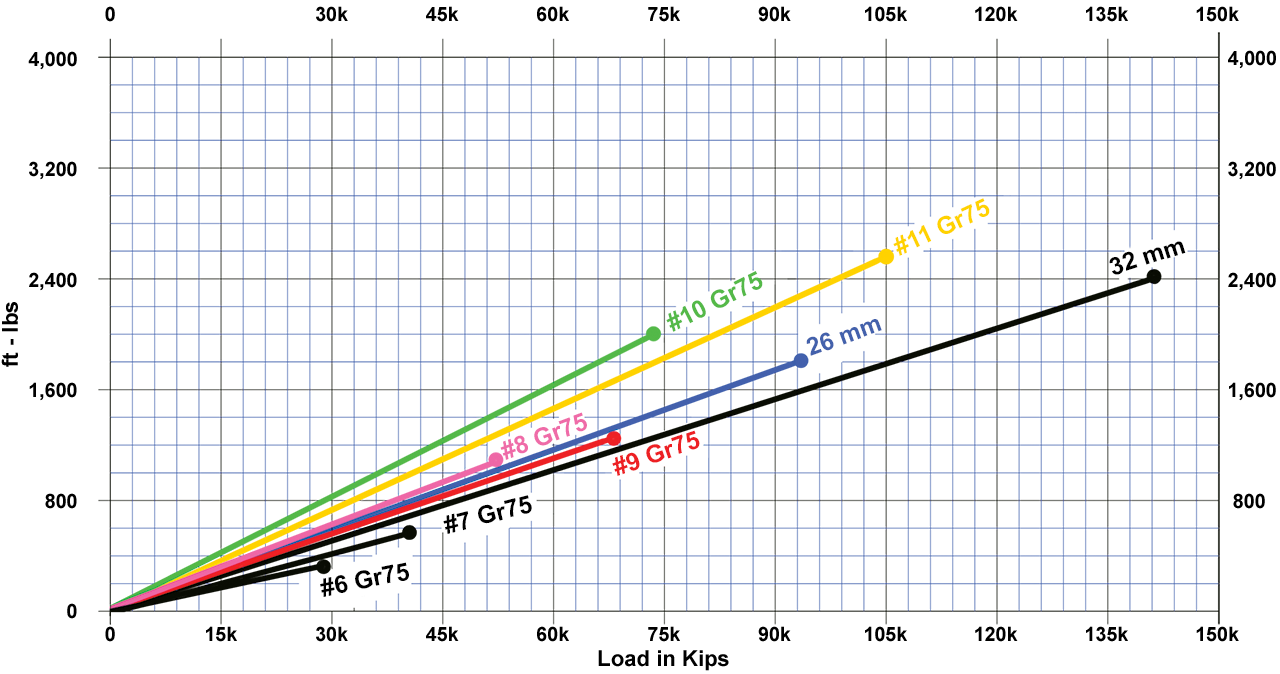

R61 Grade 75 & Grade 80 All-Thread Rebar Torque Tension Charts

All data based on greased (MolyKoat GN) threads and surfaces. Torque-tension relationships should be used as a guide and are only applicable to uncoated (plain finish) bars. Actual tension can vary significantly, and should be verified in the field. If accurate tension is required, Williams recommends tensioning using a hydraulic ram.

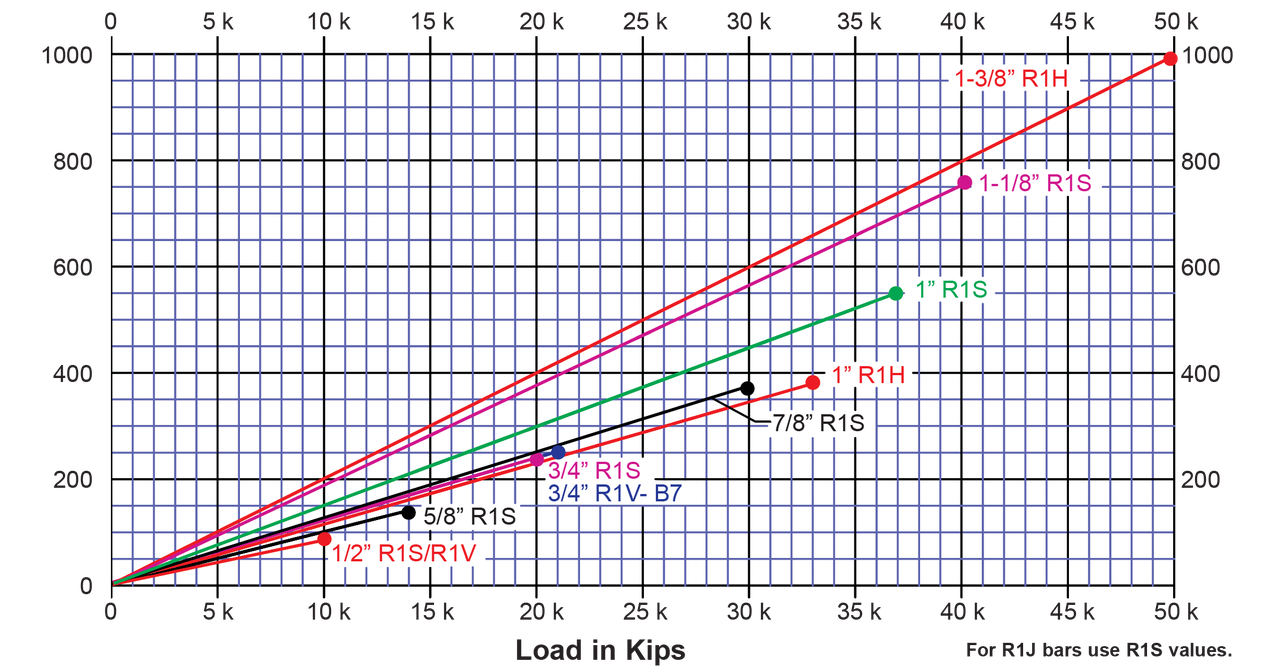

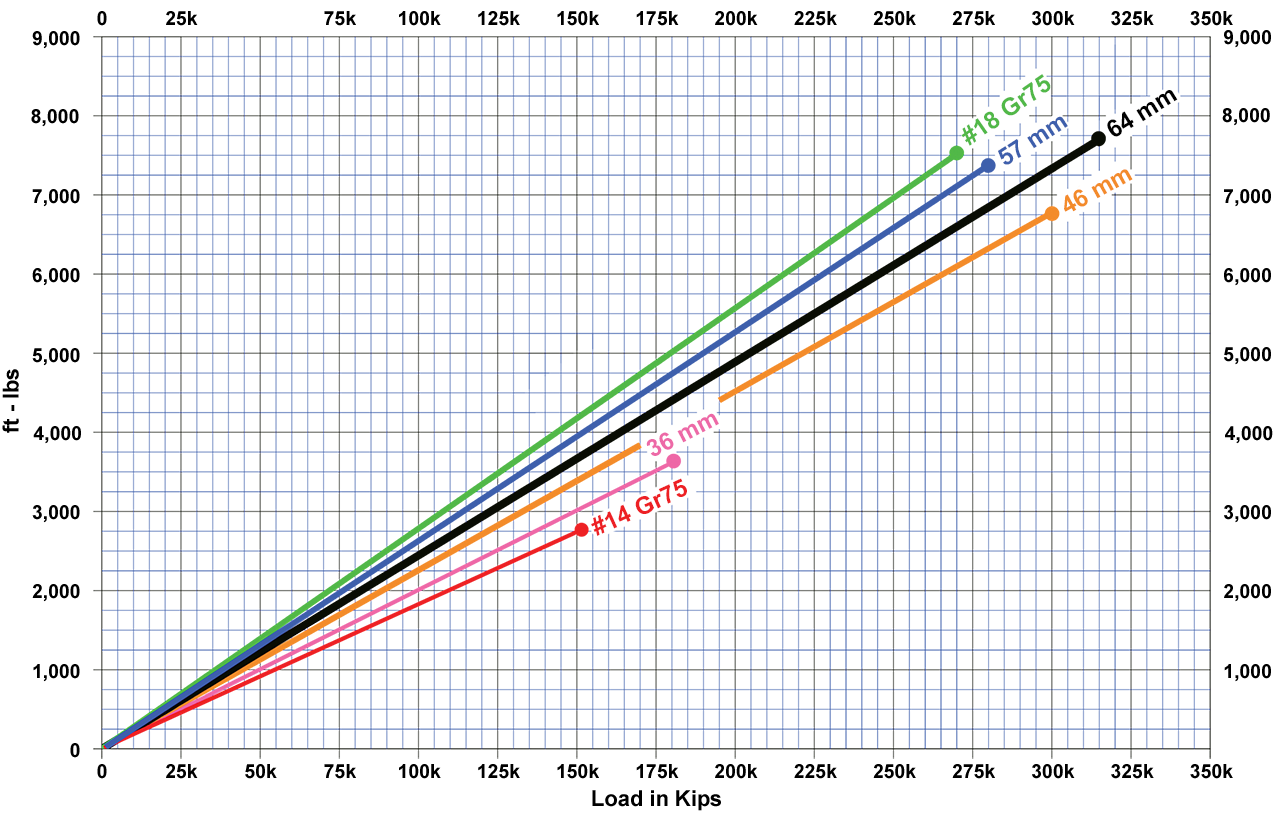

R1H Hollow-Core, R1V High Impact, R1S High Tensile, R1J Threaded Rebar & R7S 150 KSI Spin-Lock Torque Tension Charts

All data based on greased (MolyKoat GN) threads and surfaces. Torque-tension relationships should be used as a guide and are only applicable to uncoated (plain finish) bars. Actual tension can vary significantly, and should be verified in the field. If accurate tension is required, Williams recommends tensioning using a hydraulic ram.