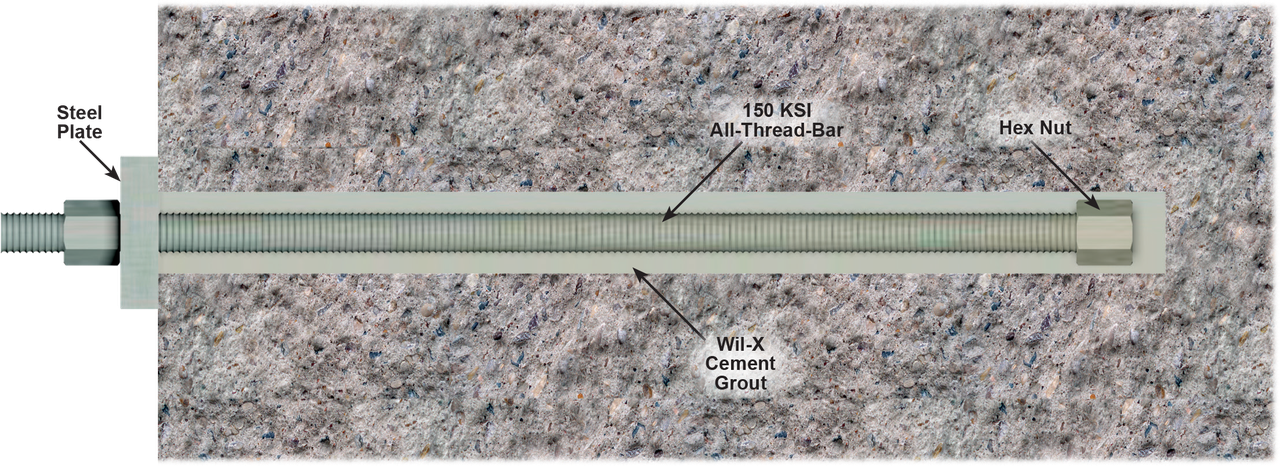

Grout Bonded Concrete Anchors

Williams’ grouted concrete anchors are post-installed bars utilizing a high strength grout for the bonding material. The advantage of using a grout versus and epoxy is cement grout does not break down in high heat areas and can be pumped into deep embedded holes easier than epoxy. The disadvantages are longer set times than epoxy and the bond stress may also be lower. Williams offers US Spec RA Grout (High Flow, Non-aggregate, Non-shrink grout) for cement grout bonded anchors. This product is manufactured by US Spec. Has excellent grout bond characteristics and quick set-up times. Click here for the RA Grout properties.

Grouted concrete anchors typically use a hex nut at the bottom of the anchor rod. This helps to assure that a failure will not occur at the grout to bar interface. The modes of failure that can be evaluated for a single grouted concrete anchor include, ductile steel failure, concrete breakout failure and bond failure. By setting the bar’s ultimate steel strength equal to the concrete breakout strength, the designer can estimate a recommended embedment depth using industry design models. In addition bond failure can be checked by using a Uniform Bond Stress Model. Presently the anchor industry is absent of a formal design code for grouted anchors, however the designer can consider the following equations taken from ACI 318-14 Chapter 17 for assistance.

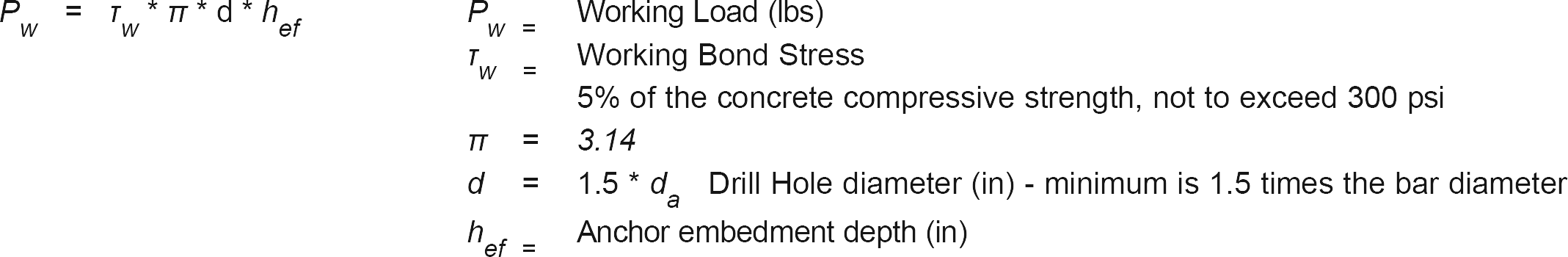

Uniform Bond Stress Model

Concrete Breakout Strength

Note: Williams recommends designing for ductile steel failure whenever possible. Steel strengths can be collected from the strength charts.