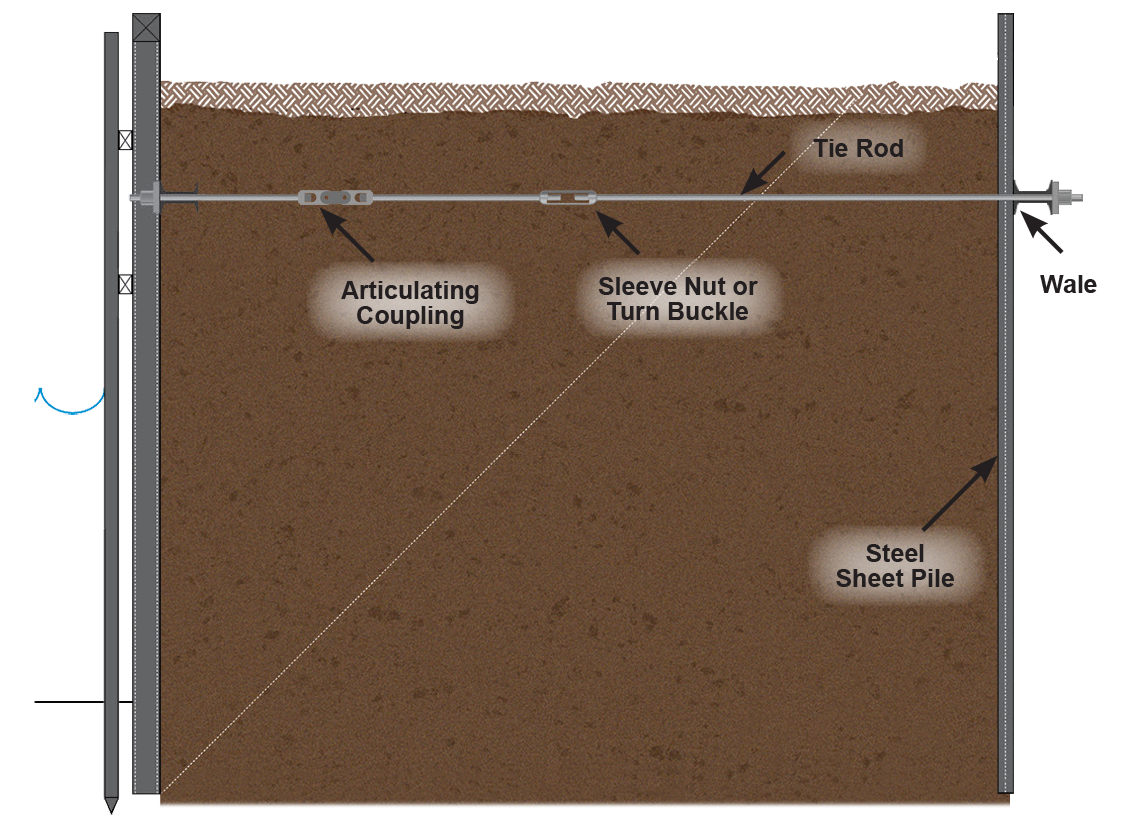

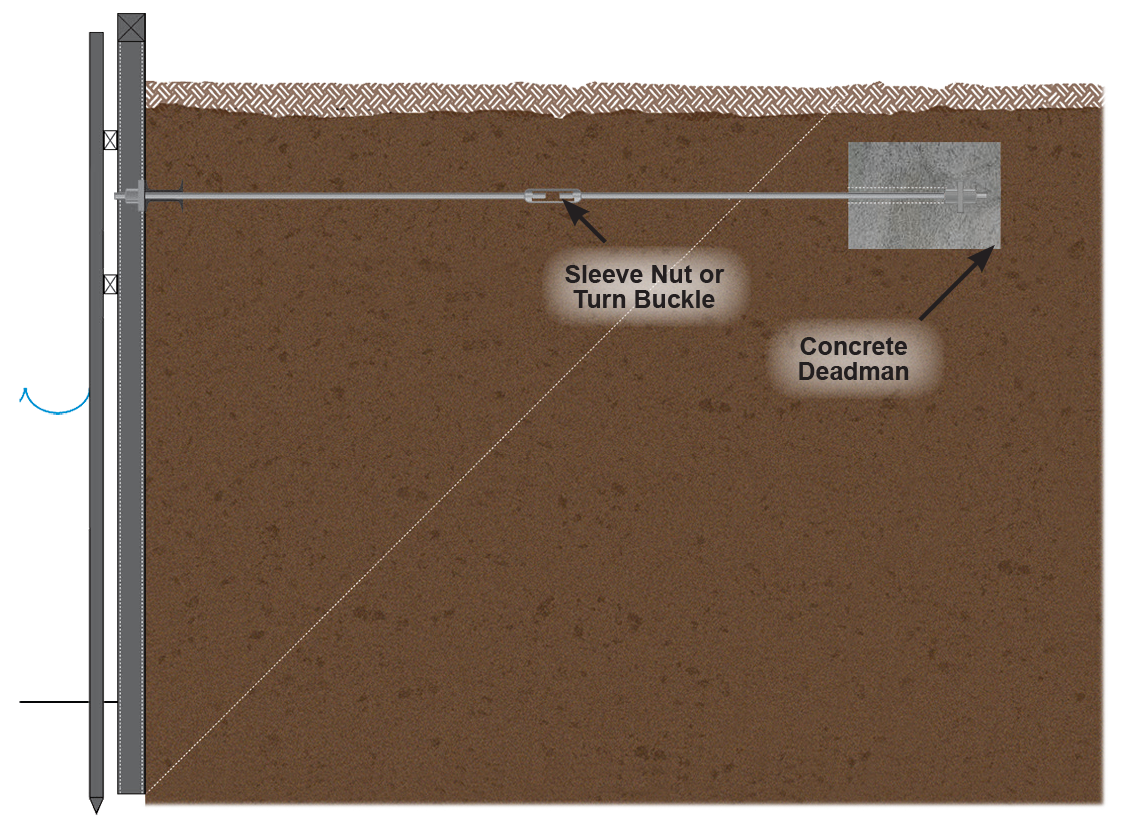

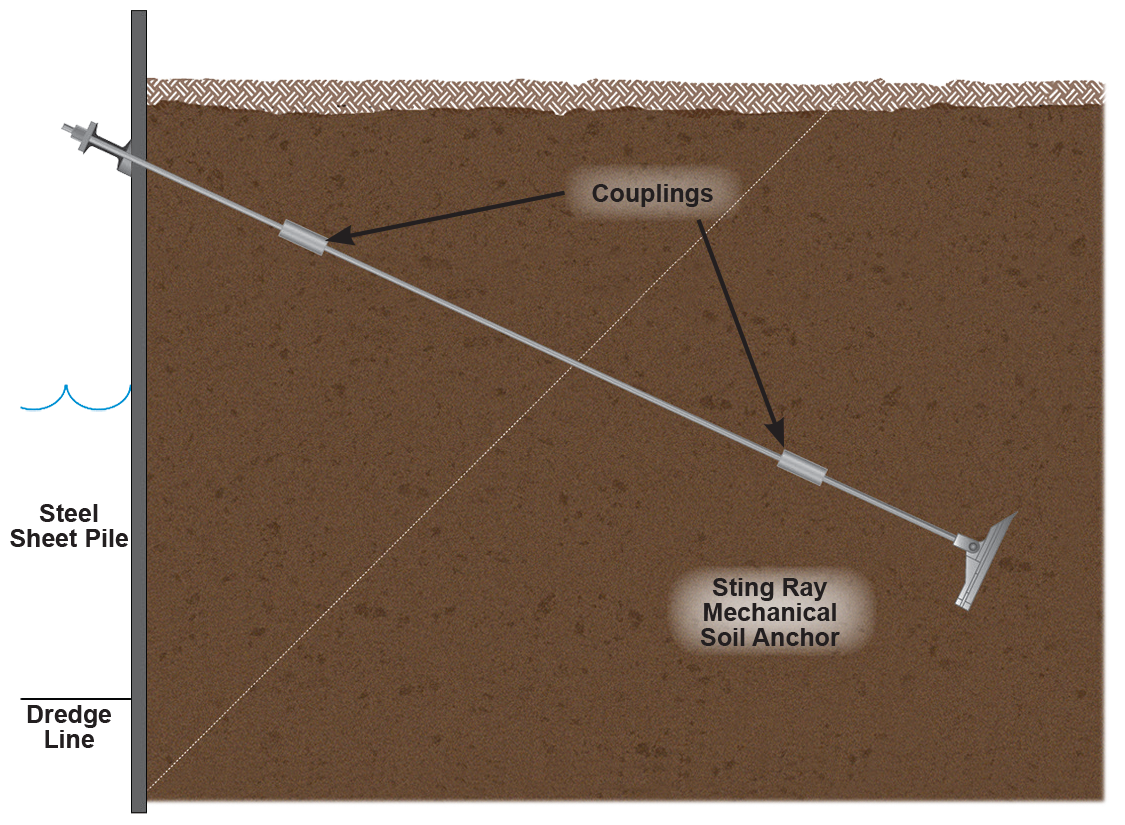

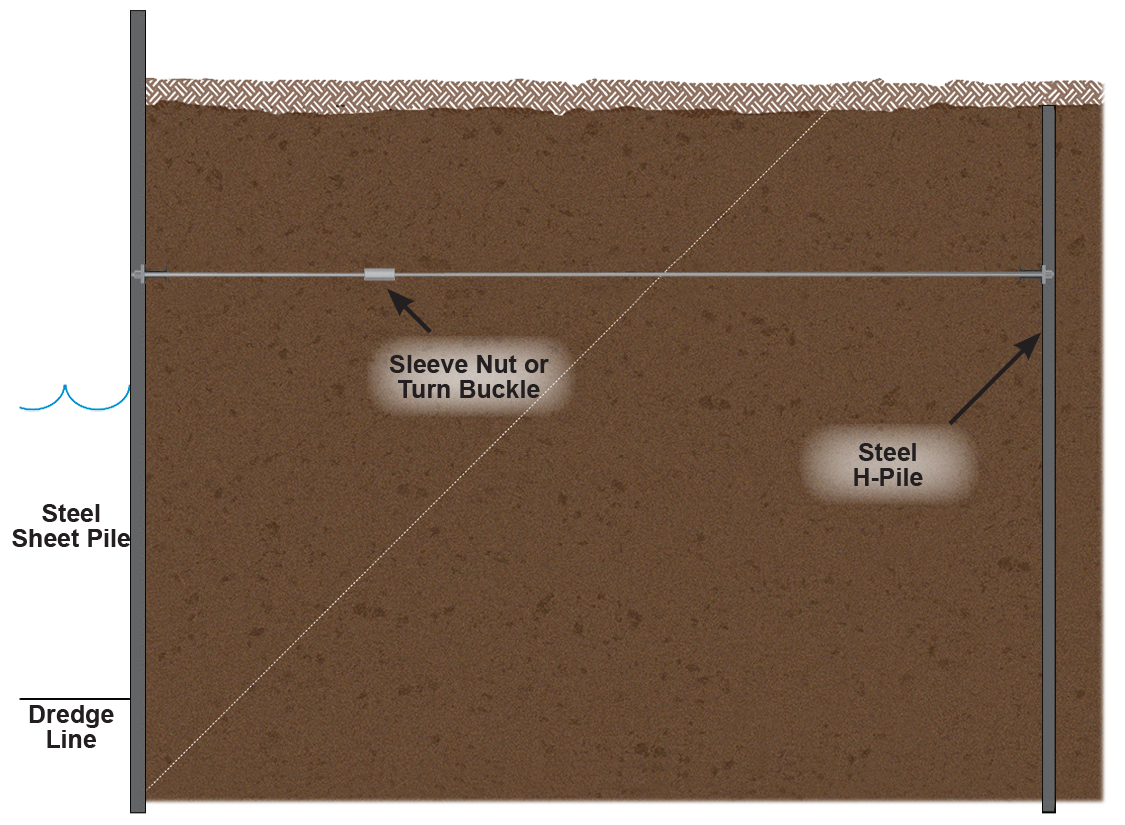

Williams Tie Rod Advantages

- Lower costs with higher strengths and lighter weights.

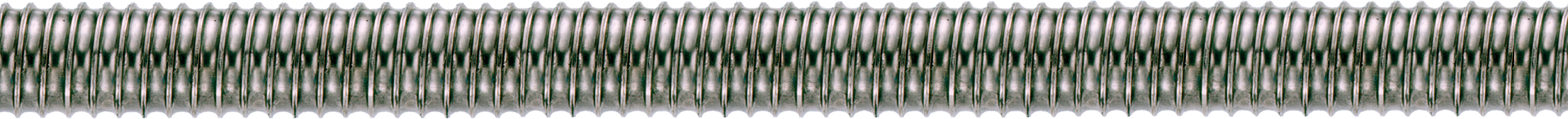

- Continuously threaded for maximum versatility or threaded on ends only

- Durable threads and components capable of developing the full capacity of the bar

- Both right hand and left hand threads available upon request to tighten tie rods using turnbuckles or sleeve nuts.

- 50 foot stock lengths, 60 foot available on special request.

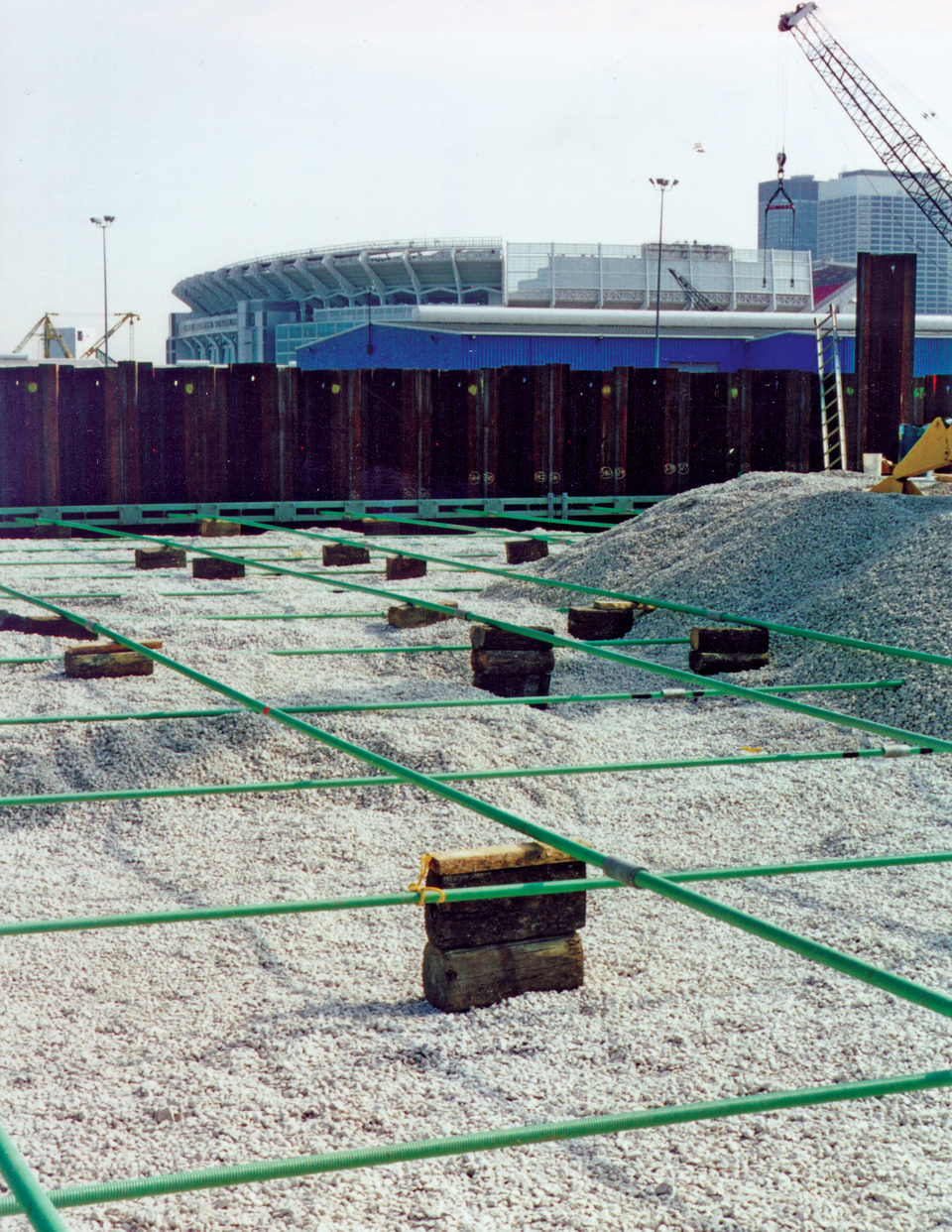

- Several options of corrosion protection available from simple coatings to advanced designs for aggressive environments.

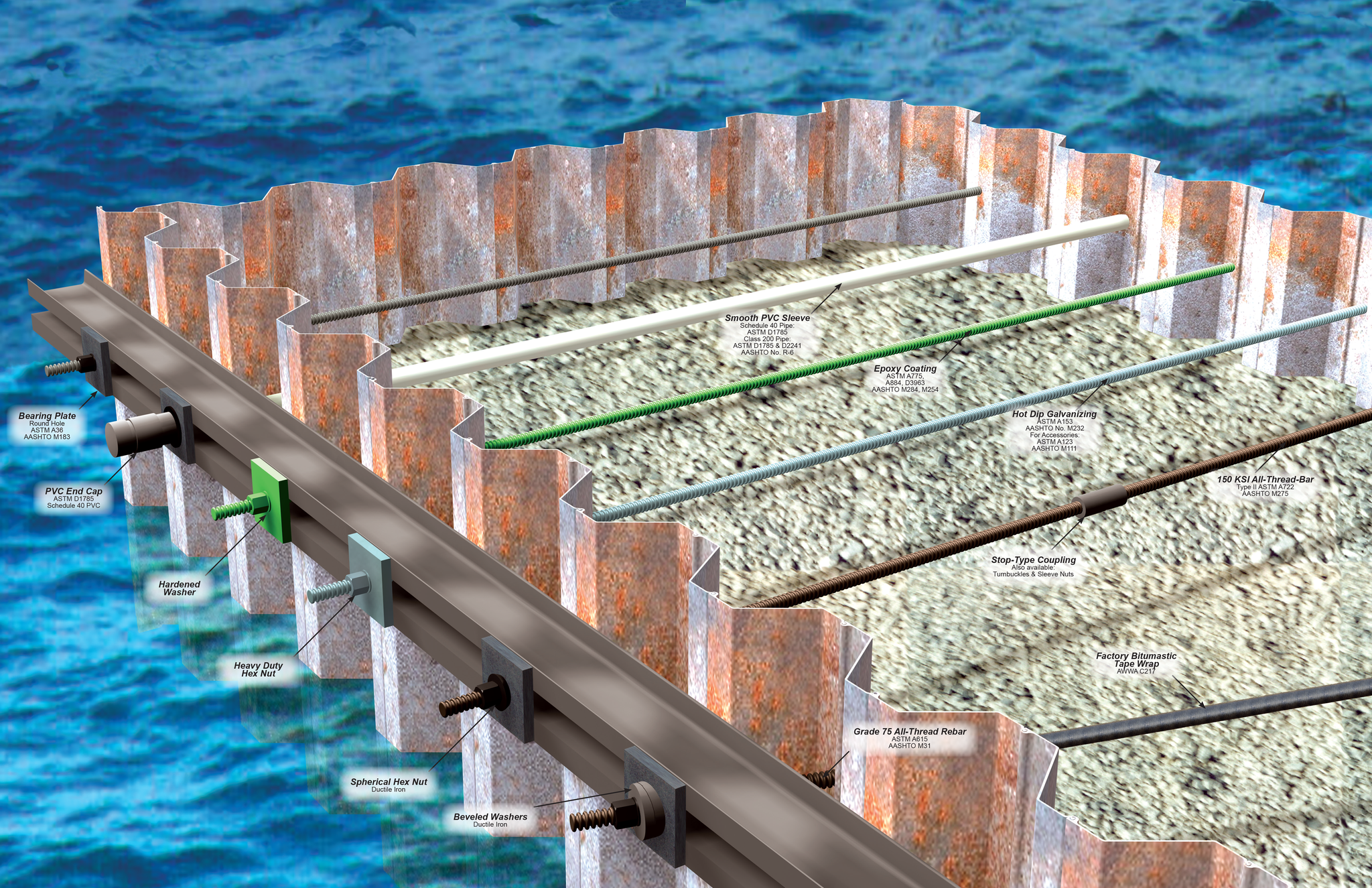

150 KSI All-Thread-Bar

Williams 150 KSI All-Thread Bar consist of high tensile steel available in seven diameters from 1” (26 mm) to 3” (75mm) with guaranteed tensile strengths up to 1027 kips (4568 kN). All diameters are available in continuous lengths up to 50’. Bars are provided with cold rolled threads over all or a portion of the bar’s length. All tension components for the systems are designed to develop 100% of the bars published ultimate strength. Bars are produced to ASTM A-722 physical standards. Williams All-Thread 150 KSI Bar must never be welded, subjected to the high heat of a torch, or used as aground. Field cutting should be done with an abrasive wheel or band saw. All components of the systems are designed and manufactured in the United States and have been proven on job sites around the world

Grade 75 All-Thread Rebar

Williams 75 All-Thread Rebar is a continuously threaded bar specially designed to be used with fasteners. Common applications for the Grade 75 All-Thread Rebar are tie rods and ground anchors. All-Thread Rebar is available in 11 diameters from #6 (20 mm) through #28 (89 mm) with ultimate tensile strengths up to 961 kips (4274 kN) and lengths up to 50feet. The bars are provided with a special thread designed to meet the requirements of ASTM A615 and Canadian RebarSpecifications CSA-G30.18-M92.

Threads are cold rolled on the entire length or a portion of the bar as desired. Because of the full 360 degrees concentric thread, Williams All-Thread Rebar should only be bent under special provisions. All tension components are designed to develop 100% of the bar’s published ultimate strengths. All components for the system are manufactured in North America.

Conversion Chart

Williams All-Thread-Bars are more economical than heavier ASTM A36 upset threaded rods. All-Thread Bars are usually on the order of 10-30% less expensive than A36 tie rods when bar comparisons are based on equivalent ultimate strengths. Not only are the bars less expensive but since the bars are smaller they are lighter. Additional savings result with smaller connectors, protective coatings and material freight. The bars below are shown in sizes relative to each other and have approximately equal yield strength.

Download the Comparison Chart as a PDF