Grade 60 All-Thread Rebar

| Bar Designation Nominal Diameter & Pitch |

Minimum Net Area Thru Threads |

Minimum Ultimate Strength |

Minimum Yield Strength |

Nominal Weight |

Approx. Thread Major Dia. |

Part Number |

|---|---|---|---|---|---|---|

| #4 – 1/2” (13 mm) |

0.2 in2 (129 mm2) |

16 kips (71.2 kN) |

12.0 kips (53.4 kN) |

0.68 lbs/ft (1.0 kg/m) |

5/8” (16 mm) |

R51-04 |

| #5 – 5/8” (16 mm) |

0.32 in2 (206 mm2) |

25.6 kips (114 kN) |

19.2 kips (85.4 kN) |

1.09 lbs/ft (1.6 kg/m) |

3/4” (19 mm) |

R51-05 |

| #6 – 3/4” – 5 (19 mm) |

0.44 in2 (284 mm2) |

35.2 kips (157 kN) |

26.4 kips (117 kN) |

1.5 lbs/ft (2.4 kg/m) |

7/8” (22 mm) |

R51-06 |

| #7 – 7/8” – 5 (22 mm) |

0.60 in2 (387 mm2) |

48.0 kips (214 kN) |

36.0 kips (160 kN) |

2.0 lbs/ft (3.0 kg/m) |

1” (25 mm) |

R51-07 |

| #8 – 1” – 3-1/2 (25 mm) |

0.79 in2 (510 mm2) |

63.2 kips (281 kN) |

47.4 kips (211 kN) |

2.7 lbs/ft (3.9 kg/m) |

1-1/8” (29 mm) |

R51-08 |

Structural Properties

| Minimum Yield |

Ultimate Tensile |

Typical Elongation in 8″ bar |

|---|---|---|

| 60 KSI (413 MPa) |

80 KSI (552 MPa) |

7% min |

Williams All-Thread Grade 60 Rebar is a continuously threaded bendable alternative to traditional rebar. All-Thread-Rebar can be spliced with a mechanical coupling which is capable of developing 100% of the bars tensile capacity.

System Advantages

The Williams All-thread Rebar Splice System allows you to field produce RebarDowel Connections from stock inventory. The ease of producing your own splices simplifies the forming operation and helps meet scheduling deadlines.

- No waiting for custom sizes or lengths

- Easy field assembly

- No special tools required

- Eliminates Protruding Dowels

- No torque requirements

- Stop type coupling ensures proper engagement

- Reduces forming and stripping cost

- Full Strength Splice

System Compliance

The Grade 60 All-Thread Rebar Splice System complies with the following standards and specifications.

- IAPMO Evaluation Report # 0205

- American Concrete Institute (ACI Standard 318)

- 2009 International Building Code (IBC)

- 2009 International Residential Code (IRC)

- State Departments of Transportation

Accessories

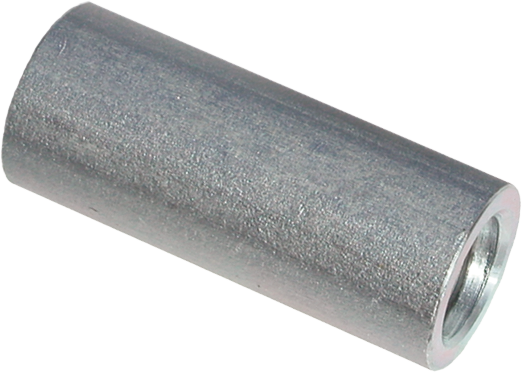

R52 Stop-Type Couplings

| Bar Desig. & Nominal Dia. |

Outside Diameter |

Overall Length |

Part Number |

|---|---|---|---|

| #4 – 1/2” (13 mm) |

15/16” (24 mm) |

2-1/8” (54 mm) |

R52-04 |

| #5 – 5/8” (16 mm) |

1-1/16” (27 mm) |

2-3/8” (60 mm) |

R52-05 |

| #6 – 3/4” (19 mm) |

1-1/4” (32 mm) |

2-3/4” (70 mm) |

R52-06 |

| #7 – 7/8” (22 mm) |

1-3/8” (35 mm) |

3-1/4” (83 mm) |

R52-07 |

| #8 – 1” (25 mm) |

1-5/8” (41 mm) |

3-7/8” (98 mm) |

R52-08 |

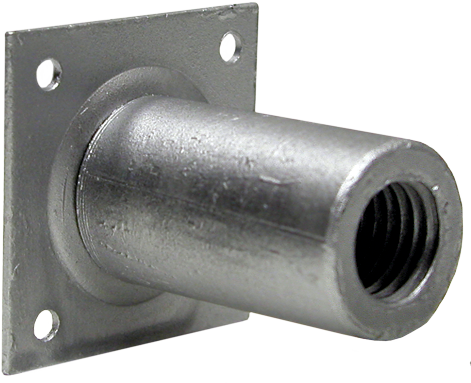

C2DD Flange Coupling

| Bar Desig. & Nominal Dia. |

Outside Diameter |

Coupling Length |

Flange Depth |

Flange Width |

Part Number |

|---|---|---|---|---|---|

| #4 – 1/2” (13 mm) |

15/16” (24 mm) |

2-1/8” (54 mm) |

0.06” (1.6 mm) |

2” (51 mm) |

C2DD-04 |

| #5 – 5/8” (16 mm) |

1-1/16” (27 mm) |

2-3/8” (60 mm) |

0.06” (1.6 mm) |

2” (51 mm) |

C2DD-05 |

| #6 – 3/4” (19 mm) |

1-1/4” (32 mm) |

2-3/4” (70 mm) |

0.06” (1.6 mm) |

2” (51 mm) |

C2DD-06 |

| #7 – 7/8” (22 mm) |

1-3/8” (35 mm) |

3-1/4” (83 mm) |

0.06” (1.6 mm) |

3” (76 mm) |

C2DD-07 |

| #8 – 1” (25 mm) |

1-5/8” (41 mm) |

3-7/8” (98 mm) |

0.06” (1.6 mm) |

3” (76 mm) |

C2DD-08 |

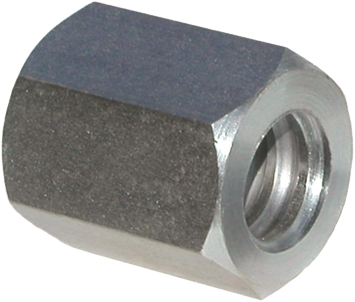

R53 Hex Nuts

| Bar Desig. & Nominal Dia. |

Across Flats |

Across Corners |

Thickness | Part Number |

|---|---|---|---|---|

| #4 – 1/2” (13 mm) |

15/16” (24 mm) |

1.08” (28 mm) |

5/8” (16m) |

R53-04 |

| #5 – 5/8” (16 mm) |

1-1/16” (27 mm) |

1.23” (31 mm) |

3/4” (19 mm) |

R53-05 |

| #6 – 3/4” (19 mm) |

1-1/4” (32 mm) |

1.44” (37 mm) |

7/8” (22 mm) |

R53-06 |

| #7 – 7/8” (22 mm) |

1-7/16” (37 mm) |

1.66” (42 mm) |

1” (25 mm) |

R53-07 |

| #8 – 1” (25 mm) |

1-5/8” (41 mm) |

1.88” (48 mm) |

1-1/8” (29 mm) |

R53-08 |

R9F Hardened Washers

| Bar Desig. & Nominal Dia. |

Outside Diameter |

Inside Diameter |

Thickness | Part Number |

|---|---|---|---|---|

| #4 – 1/2” (13 mm) |

1-5/16” (33 mm) |

11/16” (18mm) |

9/64” (3.6 mm) |

R9F-05-436 |

| #5 – 5/8” (16 mm) |

1-7/16” (37 mm) |

13/16” (21 mm) |

9/64” (3.6 mm) |

R9F-06-436 |

| #6 – 3/4” (19 mm) |

1-3/4” (45 mm) |

15/16” (24 mm) |

5/32” (4 mm) |

R9F-07-436 |

| #7 – 7/8” (22 mm) |

2” (51 mm) |

1-1/16” (29 mm) |

5/32” (4 mm) |

R9F-08-436 |

| #8 – 1” (25 mm) |

2-1/4” (57 mm) |

1-3/16” (30 mm) |

5/32” (4 mm) |

R9F-09-436 |