Polyester Resin Rock Anchor Systems

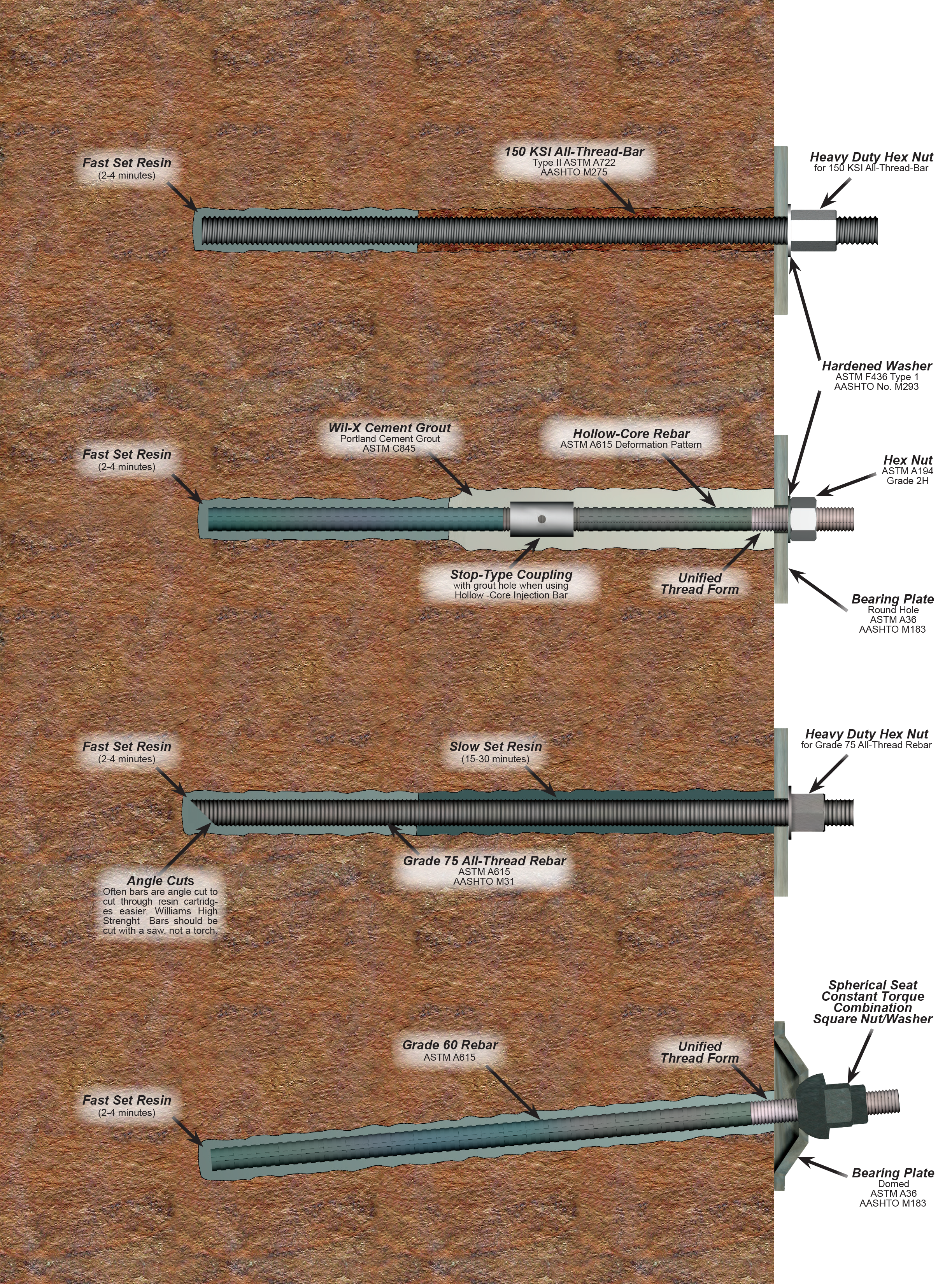

Resin anchoring provides quick rock reinforcement for active and passive installations for dams, locks, underground structures, rock cuts, and tie downs. Both Williams Grade 75 & Grade 80 and 150 KSI All-Thread Bars are used for resin anchoring.

Williams inventories quality resin cartridges. Resin cartridges consist of two components: (1) A polyester resin grout and (2) its catalyst. These precisely measured quantities are separated by a thin plastic film and are enclosed by this same film. After holes are drilled, the sausage-shaped cartridges are inserted. When rotating a deformed bar through the cartridge and into the hole, the components are mixed and the curing action begins. When cured, the comprehensive strength of the resin is often stronger than the surrounding rock. Resin systems offer a quick economical approach resulting in an encapsulated rock anchor.

Tensioned Bolts vs. Non-Tensioned Bolts

Tensioned bolt systems use fast-setting resin for anchorage in the back (bond zone) portion of the drill hole. The forward portion of the hole can be left open for temporary bolting situations, filled with slow-setting resin or pumped with cement grout depending on the situation.

Non-tensioned systems would use resin of the same set time the full length of the drill hole.

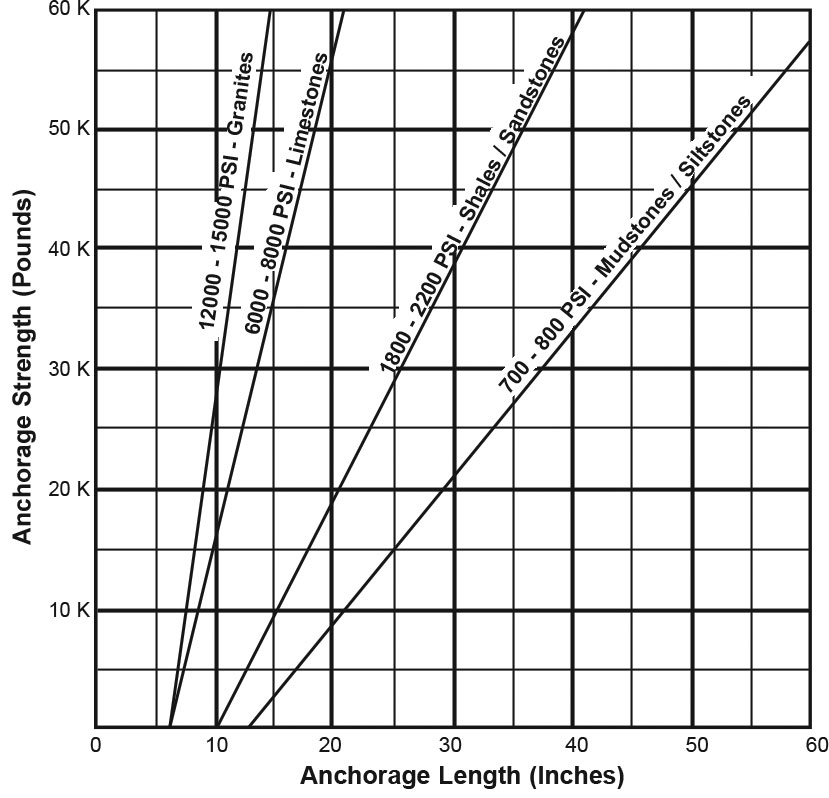

Anchorage Chart

This chart is intended as a guide for on site trials which will establish the working specifications in the actual ground conditions.

Drill Hole Fill Charts

The charts to the left show the length of drill hole that will be encapsulated by a twelve inch long polyester resin cartridge. It should be used as a guide to the most common combinations of hole diameter, bolt diameter, and resin diameter. Other combinations are possible provided the annular space does not exceed 1/4 to 3/8”.

Due to the difficulty of overcoming the drag of the bar through the resin cartridges during insertion, encapsulated resin drill holes are most practical with shorter anchorages. Other Resin Cartridge diameters may be available upon special order.

1-1/4″ (32 mm) Resin Cartridge

| Steel Type |

Bar Diameter |

Drill Hole | ||

|---|---|---|---|---|

| 1-3/8” (35 mm) |

1-1/2” (38 mm) |

1-5/8” (41 mm) |

||

| Grade 75 & Grade 80 All-Thread RebarGrade 60 Rebar |

#7 – 7/8” (22 mm) |

14.4” (366 mm) |

– | – |

| #8 – 1” (25 mm) |

18.2” (462 mm) |

13” (330 mm) |

– | |

| #9 – 1-1/8” (28 mm) |

– | 16” (406 mm) |

11.8” (300 mm) |

|

| #10 – 1-1/4” (32 mm) |

– | – | 15” (381 mm) |

|

| 150 KSI All-Thread-Bar |

1” (26 mm) |

15” (381 mm) |

12” (305 mm) |

– |

1-9/16″ (40 mm) Resin Cartridge

| Steel Type |

Bar Diameter |

Drill Hole | |||

|---|---|---|---|---|---|

| 1-3/4” (45 mm) |

1-7/8” (48 mm) |

2” (51 mm) |

2-1/4” (57 mm) |

||

| Grade 75 & Grade 80 All-Thread RebarGrade 60 Rebar |

#9 – 1-1/8” (28 mm) |

14.1” (358 mm) |

11.2” (284 mm) |

– | – |

| #10 – 1-1/4” (32 mm) |

16.9” (429 mm) |

13” (330 mm) |

10.4” (264 mm) |

– | |

| #11 – 1-3/8” (35 mm) |

23” (584 mm) |

16” (406 mm) |

12” (305 mm) |

– | |

| #14 – 1-3/4” (45 mm) |

– | – | – | 12.7” (323 mm) |

|

| 150 KSI All-Thread-Bar |

1-1/4” (32 mm) |

20” (508 mm) |

14” (356 mm) |

10.5” (267 mm) |

– |

| 1-3/8” (36 mm) |

– | 17” (432 mm) |

14” (356 mm) |

– | |

| 1-3/4” (46 mm) |

– | – | – | 16” (406 mm) |

|