Micropile Accessories

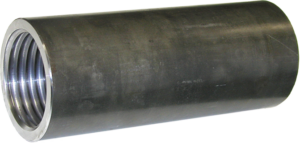

Compression Sleeves

Compression Sleeves are smaller in diameter than standard coupings and are offered for use in splicing steel reinforcement for compression-only micropile designs. Compression Sleeves offer the advantage of designing around smaller diameter casings. Compression Sleeves will not develop the full tensile strength of the bar.

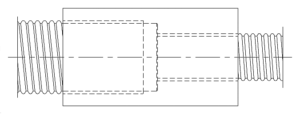

Reducer Coupling

Reducer Couplings are available to transition from a larger diameter bar to a smaller diameter bar. Reducer Couplings will develop the full ultimate strength of the smaller diameter bar.

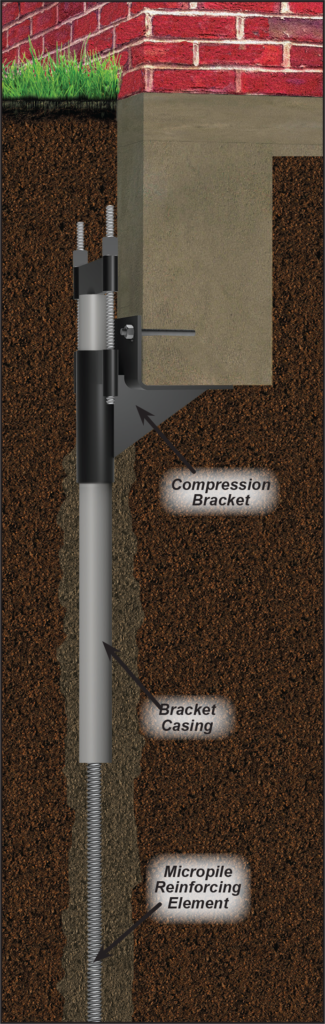

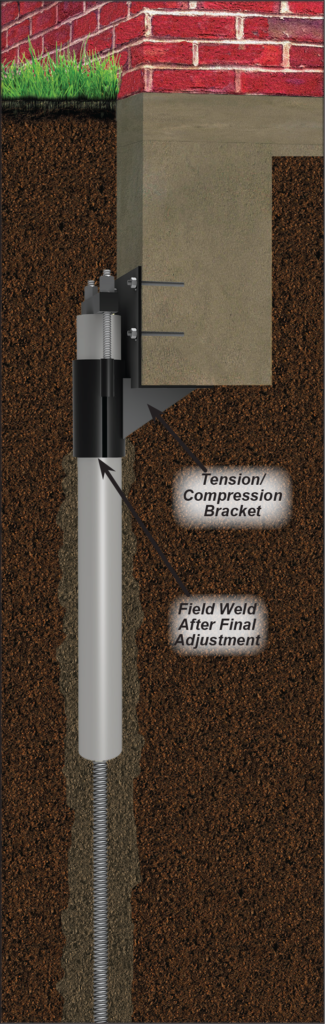

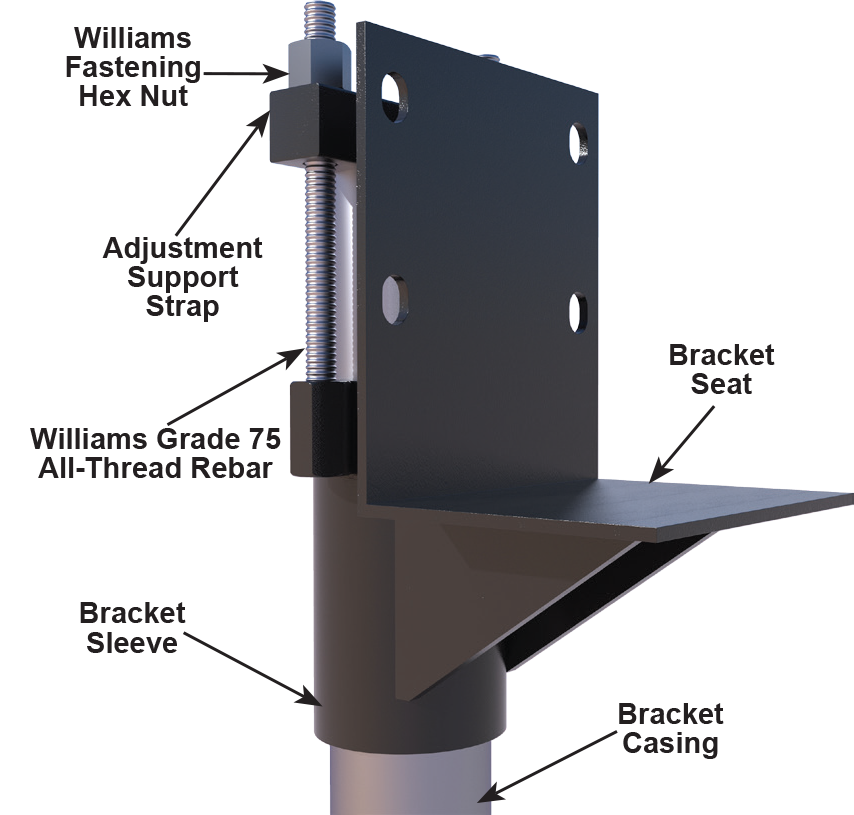

Micropile Remedial Repair Underpinning Brackets

Williams Form Engineering Corp. offers underpinning brackets for compression foundation remediation, tension/compression foundation remediation and floorslab remediation applications. Compression foundation remediation and tension/compression foundation remediation brackets are offered in three sizes ranging from 20 kip to 63 kip allowable capacities where the bracket is attached to a grouted micropile casing in medium stiff soils (N>4). The unbraced length of micropile is minimum 5’; so per section 1810.2.1 of IBC, a casing length of min 6’ is required to resist buckling and bending stresses. Brackets can be used in soft soils (N<4), however, the capacity may be reduced as the unbraced length of the micropile would be greatly increased in weaker soils. Please consult with a professional engineer to determine allowable working design load.

Compression Underpinning Bracket (C)

Supports and raises existing foundations via connection to grouted micropile casing.

| Bracket Number |

Allowable Bracket Capacity * |

Bracket Sleeve | Bracket Seat | Bracket Casing ** | ||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thickness |

Bearing Area |

OD | Wall Thickness |

Standard Length |

Yield Stress |

||

| WMS-MPB-20-C | 20 kips (88.9 kN) |

3-1/2” (89 mm) |

1/4” (6.4 mm) |

90 in² (580 cm²) |

2-7/8” (73 mm) |

0.22” (5.5 mm) |

6’ (1.8 m) |

65 KSI (448 Mpa) |

| WMS-MPB-40-C | 40 kips (178 kN) |

5-9/16” (141 mm) |

3/8” (9.5 mm) |

90 in² (580 cm²) |

4-1/2” (114 mm) |

0.44” (11.1 mm) |

6’ (1.8 m) |

65 KSI (448 Mpa) |

| WMS-MPB-63-C | 63 kips (280 kN) |

6-5/8” (168 mm) |

0.43” (11 mm) |

90 in² (580 cm²) |

5-9/16” (141 mm) |

0.26” (6.6 mm) |

6’ (1.8 m) |

36 KSI (248 Mpa) |

* Allowable bracket capacity is based on the usage of an equal or greater size, grade, and length of bracket casing shown in the chart above and assumes the back of the bracket seat is no more than 1.5” from the edge of the footing.

** WFEC does not provide the bracket casing

Tension/Compression Underpinning Bracket (TC)

- Supports and raises existing foundations via connection to grouted micropile casing.

- In tension, bracket requires a postive connection to the foundation through four 1” diameter concrete anchors bolts designed to have adequate shear capacity from seismic and wind loads. To complete the tension load path, the bracket must be positively connected to the micopile casing by field welding the bracket sleeve to the mircropile casing or by attaching shear bolts from the bracket sleeve through the micropile casing.

| Bracket Number |

Allowable Bracket Capacity * |

Bracket Sleeve | Bracket Seat | Bracket Casing ** | ||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thickness |

Bearing Area |

OD | Wall Thickness |

Standard Length |

Yield Stress |

||

| WMS-MPB-20-TC | 20 kips (89 kN) |

3-1/2” (89 mm) |

1/4” (6.4 mm) |

90 in² (580 cm²) |

2-7/8” (73 mm) |

0.22” (5.5 mm) |

6’ (1.8 m) |

65 KSI (448 Mpa) |

| WMS-MPB-40-TC | 40 kips (178 kN) |

5-9/16” (141 mm) |

3/8” (9.5 mm) |

90 in² (580 cm²) |

4-1/2” (114 mm) |

0.44” (11 mm) |

6’ (1.8 m) |

65 KSI (448 Mpa) |

| WMS-MPB-63-TC | 63 kips (280 kN) |

6-5/8” (168 mm) |

0.43” (11 mm) |

90 in² (580 cm²) |

5-9/16” (141 mm) |

0.26” (6.6 mm) |

6’ (1.8 m) |

36 KSI (248 Mpa) |

* Allowable bracket capacity is based on the usage of an equal or greater size, grade, and length of bracket casing shown in the chart above and assumes the back of the bracket seat is no more than 1.5” from the edge of the footing.

** WFEC does not provide the bracket casing

Floor Slab Underpinning Bracket (FS)

- Capacity of 11.7 Kips to support and raise existing slab-on grade concrete supported by grouted micropile.

- Bracket should be installed through a 10” diameter hole in the existing floor slab.

- Casing should be set at a sufficient height above the bracket sleeve such that the fastening nuts and support strap are below the finished floor elevation after the slab has been raised.

- The spacing of the floor slab micropiles shall be the lesser of the slab punching shear capacity and the flexural strength of the floor slab to span between the piles or the bracket capacity. Consult with a professional engineer to determine the maximum spacing of the micropiles.

- Excavation under slab required.

| Bracket Number |

Allowable Bracket Capacity * |

Bracket Sleeve | Bracket Seat | Bracket Casing ** | ||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thickness |

Bearing Area |

OD | Wall Thickness |

Standard Length |

Yield Stress |

||

| WMS-MPB-11.7-FS | 11.7 kips (52 kN) |

3-1/2” (89 mm) |

1/4” (6.4 mm) |

40 in² (258 cm²) |

2-7/8” (73 mm) |

0.22” (5.5 mm) |

6’ (1.8 m) |

65 KSI (448 Mpa) |

* Allowable bracket capacity is based on the usage of an equal or greater size, grade, and length of bracket casing shown in the chart above.

** WFEC does not provide the bracket casing