Strand Anchor System Accessories

| Number of Strands |

Cross-Sectional Area (Aps) |

Ultimate Load (fpu*Aps) |

Maximum Jacking Load (0.8*fpu*Aps) |

Maximum Design Load (0.6*fpu*Aps) |

HDPE Tubing |

Anchor Heads |

Weight per Foot |

|---|---|---|---|---|---|---|---|

| 1 | 0.217 in2 (140 mm2) |

58.6 kips (261 kN) |

46.9 kips (209 kN) |

35.2 kips (157 kN) |

3” nom (3.5” OD) |

C4.6 | 0.74 lbs (0.34 kg) |

| 2 | 0.434 in2 (280 mm2) |

117 kips (522 kN) |

93.8 kips (418 kN) |

70.4 kips (314 kN) |

3” nom (3.5” OD) |

C4.6 | 1.48 lbs (0.67 kg) |

| 3 | 0.651 in2 (420 mm2) |

176 kips (783 kN) |

141 kips (627 kN) |

106 kips (471 kN) |

3” nom (3.5” OD) |

C4.6 | 2.22 lbs (1.01 kg) |

| 4 | 0.868 in2 (560 mm2) |

234 kips (1044 kN) |

188 kips (836 kN) |

141 kips (628 kN) |

3” nom (3.5” OD) |

C7.6 – Class 1 C4.6 – Class 2 |

2.96 lbs (1.34 kg) |

| 5 | 1.09 in2 (700 mm2) |

293 kips (1305 kN) |

235 kips (1045 kN) |

176 kips (785 kN) |

3” nom (3.5” OD) |

C7.6 | 3.70 lbs (1.68 kg) |

| 6 | 1.30 in2 (840 mm2) |

352 kips (1566 kN) |

281 kips (1254 kN) |

211 kips (942 kN) |

3” nom (3.5” OD) |

C7.6 | 4.44 lbs (2.01 kg) |

| 7 | 1.52 in2 (980 mm2) |

410 kips (1827 kN) |

328 kips (1463 kN) |

246 kips (1099 kN) |

3” nom (3.5” OD) |

C7.6 | 5.18 lbs (2.35 kg) |

| 8 | 1.74 in2 (1120 mm2) |

469 kips (2088 kN) |

375 kips (1672 kN) |

282 kips (1256 kN) |

3” nom (3.5” OD) |

C9.6 | 5.92 lbs (2.69 kg) |

| 9 | 1.95 in2 (1260 mm2) |

527 kips (2349 kN) |

422 kips (1881 kN) |

317 kips (1413 kN) |

4” nom (4.6” OD) |

C9.6 | 6.66 lbs (3.02 kg) |

| 10 | 2.17 in2 (1400 mm2) |

586 kips (2610 kN) |

469 kips (2090 kN) |

352 kips (1570 kN) |

4” nom (4.6” OD) |

C12.6 | 7.40 lbs (3.36 kg) |

| 11 | 2.39 in2 (1540 mm2) |

645 kips (2871 kN) |

516 kips (2299 kN) |

387 kips (1727 kN) |

4” nom (4.6” OD) |

C12.6 | 8.14 lbs (3.69 kg) |

| 12 | 2.60 in2 (1680 mm2) |

703 kips (3132 kN) |

563 kips (2508 kN) |

422 kips (1884 kN) |

4” nom (4.6” OD) |

C12.6 | 8.88 lbs (4.03 kg) |

| 13 | 2.82 in2 (1820 mm2) |

762 kips (3393 kN) |

610 kips (2717 kN) |

458 kips (2041 kN) |

4” nom (4.6” OD) |

C19.6 | 9.62 lbs (4.36 kg) |

| 14 | 3.04 in2 (1960 mm2) |

820 kips (3654 kN) |

657 kips (2926 kN) |

493 kips (2198 kN) |

4” nom (4.6” OD) |

C19.6 | 10.36 lbs (4.70 kg) |

| 15 | 3.26 in2 (2100 mm2) |

879 kips (3915 kN) |

704 kips (3135 kN) |

528 kips (2355 kN) |

4” nom (4.6” OD) |

C19.6 | 11.10 lbs (5.03 kg) |

| 16 | 3.47 in2 (2240 mm2) |

938 kips (4176 kN) |

750 kips (3344 kN) |

563 kips (2512 kN) |

5” nom (5.6” OD) |

C19.6 | 11.84 lbs (5.37 kg) |

| 17 | 3.69 in2 (2380 mm2) |

996 kips (4437 kN) |

797 kips (3553 kN) |

598 kips (2669 kN) |

5” nom (5.6” OD) |

C19.6 | 12.58 lbs (5.71 kg) |

| 18 | 3.91 in2 (2520 mm2) |

1055 kips (4698 kN) |

844 kips (3762 kN) |

634 kips (2826 kN) |

5” nom (5.6” OD) |

C19.6 | 13.32 lbs (6.04 kg) |

| 19 | 4.12 in2 (2660 mm2) |

1113 kips (4959 kN) |

891 kips (3971 kN) |

669 kips (2983 kN) |

5” nom (5.6” OD) |

C19.6 | 14.06 lbs (6.38 kg) |

| 20 | 4.34 in2 (2800 mm2) |

1172 kips (5220 kN) |

938 kips (4180 kN) |

704 kips (3140 kN) |

5” nom (5.6” OD) |

C22.6 | 14.80 lbs (6.71 kg) |

| 21 | 4.56 in2 (2940 mm2) |

1231 kips (5481 kN) |

985 kips (4389 kN) |

739 kips (3297 kN) |

6” nom (6.6” OD) |

C22.6 | 15.54 lbs (7.05 kg) |

| 22 | 4.77 in2 (3080 mm2) |

1289 kips (5742 kN) |

1032 kips (4598 kN) |

774 kips (3454 kN) |

6” nom (6.6” OD) |

C22.6 | 16.28 lbs (7.38 kg) |

| 23 | 4.99 in2 (3220 mm2) |

1348 kips (6003 kN) |

1079 kips (4807 kN) |

810 kips (3611 kN) |

6” nom (6.6” OD) |

C27.6 | 17.02 lbs (7.72 kg) |

| 24 | 5.21 in2 (3360 mm2) |

1406 kips (6264 kN) |

1126 kips (5016 kN) |

845 kips (3768 kN) |

6” nom (6.6” OD) |

C27.6 | 17.76 lbs (8.06 kg) |

| 25 | 5.43 in2 (3500 mm2) |

1465 kips (6525 kN) |

1173 kips (5225 kN) |

880 kips (3925 kN) |

6” nom (6.6” OD) |

C27.6 | 18.50 lbs (8.39 kg) |

| 26 | 5.64 in2 (3640 mm2) |

1524 kips (6786 kN) |

1219 kips (5434 kN) |

915 kips (4082 kN) |

6” nom (6.6” OD) |

C27.6 | 19.24 lbs (8.73 kg) |

| 27 | 5.86 in2 (3780 mm2) |

1582 kips (7047 kN) |

1266 kips (5643 kN) |

950 kips (4239 kN) |

6” nom (6.6” OD) |

C27.6 | 19.98 lbs (9.06 kg) |

| 28 | 6.08 in2 (3920 mm2) |

1640 kips (7308 kN) |

1313 kips (5852 kN) |

986 kips (4396 kN) |

6” nom (6.6” OD) |

C31.6 | 20.72 lbs (9.40 kg) |

| 29 | 6.29 in2 (4060 mm2) |

1699 kips (7569 kN) |

1360 kips (6061 kN) |

1021 kips (4553 kN) |

6” nom (6.6” OD) |

C31.6 | 21.46 lbs (9.73 kg) |

| 30 | 6.51 in2 (4200 mm2) |

1758 kips (7820 kN) |

1407 kips (6270 kN) |

1056 kips (4710 kN) |

6” nom (6.6” OD) |

C31.6 | 22.20 lbs (10.07 kg) |

| 31 | 6.73 in2 (4340 mm2) |

1816 kips (8091 kN) |

1454 kips (6479 kN) |

1091 kips (4867 kN) |

6” nom (6.6” OD) |

C31.6 | 22.94 lbs (10.41 kg) |

| 32 | 6.94 in2 (4480 mm2) |

1875 kips (8352 kN) |

1500 kips (6688 kN) |

1126 kips (5024 kN) |

8” nom (9-1/2” OD) |

C37.6 | 23.68 lbs (10.74 kg) |

| 37 | 8.03 in2 (5180 mm2) |

2168 kips (9657 kN) |

1735 kips (7733 kN) |

1302 kips (5809 kN) |

8” nom (9-1/2” OD) |

C37.6 | 27.38 lbs (12.42 kg) |

| 55 | 11.94 in2 (7700 mm2) |

3223 kips (14337 kN) |

2578 kips (11468 kN) |

1934 kips (8603 kN) |

10” nom (11.9” OD) |

C55.6 | 40.70 lbs (18.46 kg) |

| 61 | 13.24 in2 (8540 mm2) |

3575 kips (15901 kN) |

2860 kips (12722 kN) |

2145 kips (9541 kN) |

10” nom (11.9” OD) |

C61.6 | 45.14 lbs (20.48 kg) |

1) Mill certification provided upon request to indicate the actual tensile strength of the 7-wire strand with each shipment of Williams strand anchors.

2) Larger diameter anchors available upon request.

3) Minimum grout cover shall be 1/2” (13mm) over the OD of the encapsulation in a Class I Protected anchor and 1/2” (13mm) over the tendon bond length in a Class II protected anchor.

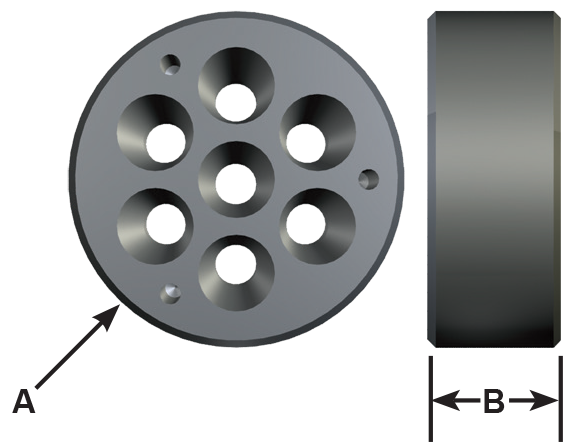

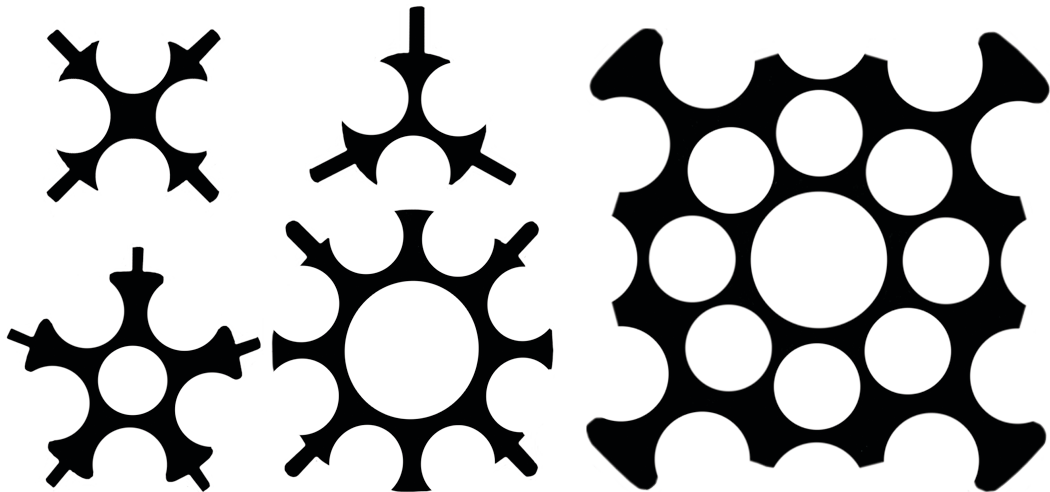

Wedge Plates (Anchor Heads)

Williams Wedge Plates are full strength permanent components. Williams C4.6 and C7.6 Plates are prequalified by CALTRANS, with approval Nos. 040114a & 040114b respectively, for prestressed ground anchor construction.

| Type | A Diameter |

B Thickness |

Part Number |

|---|---|---|---|

| C4.6 | 4-1/4” (108 mm) |

2” (51 mm) |

RSAH04W |

| C7.6 | 5” (127 mm) |

2” (51 mm) |

RSAH07W |

| C9.6 | 6-3/8” (162 mm) |

2-3/4” (70 mm) |

RSAH09W |

| C12.6 | 7-1/4” (184 mm) |

3” (78 mm) |

RSAH12S |

| C19.6 | 8-3/8” (213 mm) |

3-3/4” (95 mm) |

RSAH19S |

| C22.6 | 9” (229 mm) |

3-3/4” (95 mm) |

RSAH22 |

| C27.6 | 10” (254 mm) |

4” (102 mm) |

RSAH27 |

| C31.6 | 10-3/4” (273 mm) |

4-7/8” (122 mm) |

RSAH31 |

| C37.6 | 11-1/2” (292 mm) |

4-7/8” (122 mm) |

RSAH37 |

| C55.6 | 13-1/2” (343 mm) |

6-3/8” (162 mm) |

RSAH55 |

| C61.6 | 14-1/2” (368 mm) |

6-1/2” (165 mm) |

RSAH61 |

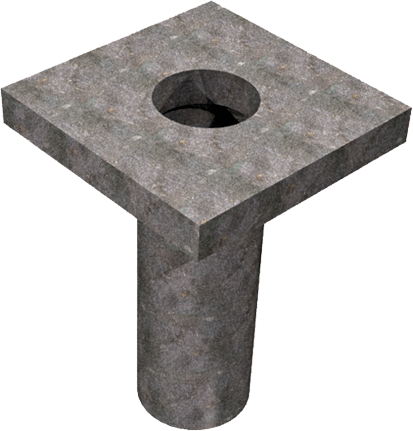

Bearing Plates

Williams Bearing Plates are available in sizes as required per anchor, and are designed in accordance with PTI specifications. Plate stock can be provided in Grade 36 or Grade 50. All plates are available galvanized upon request.

| Type | Trumpet | Center Hole Head Clearance |

|

|---|---|---|---|

| OD | ID (Nom) | ||

| C4.6 | 4-1/2” (114 mm) |

4” (102 mm) |

3-3/8” (86 mm) |

| C7.6 | 4-1/2” (114 mm) |

4” (102 mm) |

3-3/4” (95 mm) |

| C9.6 | 5-9/16” (141 mm) |

5” (127 mm) |

4-5/8” (117 mm) |

| C12.6 | 6-5/8” (168 mm) |

6” (152 mm) |

5-3/8” (137 mm) |

| C19.6 | 7-5/8” (194 mm) |

7-1/8” (181 mm) |

6-1/2” (165 mm) |

| C22.6 | 8-5/8” (219 mm) |

7-7/8” (200 mm) |

7-1/2” (191 mm) |

| C27.6 | 8-5/8” (219 mm) |

7-7/8” (200 mm) |

8” (203 mm) |

| C31.6 | 10-3/4” (273 mm) |

10” (254 mm) |

8-1/2” (216 mm) |

| C37.6 | 10-3/4” (273 mm) |

10” (254 mm) |

9-1/2” (241 mm) |

| C55.6 | 12-3/4” (324 mm) |

12” (305 mm) |

10-1/2” (267 mm) |

| C61.6 | 12-3/4” (324 mm) |

12” (305 mm) |

11-1/2” (292 mm) |

Steel End Caps

Williams offers a bolt-on steel end cap to provide corrosion protection for exposed anchor ends. Caps are provided with a closed cell neoprene seal. Most often the caps are packed with corrosion inhibiting wax or grease.

| Type | Pipe Outer Diameter |

Flange Diameter |

Height |

|---|---|---|---|

| C4.6 | 5-9/16” (141 mm) |

8” (203 mm) |

4-5/8” (117 mm) |

| C7.6 | 6-5/8” (168 mm) |

8” (203 mm) |

4-5/8” (117 mm)> |

| C9.6 | 8-5/8” (219 mm) |

10” (254 mm) |

5-3/8” (137 mm) |

| C12.6 | 8-5/8” (219 mm) |

10” (254 mm) |

5-3/8” (137 mm) |

| C19.6 | 10-3/4” (273 mm) |

12” (305 mm) |

6” (152 mm) |

| C22.6 | 10-3/4” (273 mm) |

12” (305 mm) |

6” (152 mm) |

| C27.6 | 10-3/4” (273 mm) |

14” (356 mm) |

7-7/8” (200 mm) |

| C31.6 | 12-3/4” (324 mm) |

14” (356 mm) |

7-7/8” (200 mm) |

| C37.6 | 12-3/4” (324 mm) |

14” (356 mm) |

8-7/8” (225 mm) |

| C55.6 | 16” (406 mm) |

18” (457 mm) |

12” (305 mm) |

| C61.6 | 16” (406 mm) |

18” (457 mm) |

12” (305 mm) |

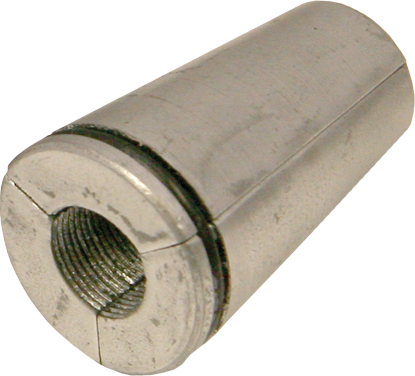

Anchor Head Wedges

RSWG03

All wedges are equipped with a ring to keep the wedge attached to the tendon during elongation and/or tensioning operations.

The 3-Piece anchor wedges are PTI recommended for use on permanent anchors and/or anchors requiring incremental loading. They uniformly engage the strand with less relaxation at low loads. They are manufactured from quality steels and are carburized for durability.

Stressing Head Wedges

RSXSHW

Stressing head wedges are necessary for prestressing all classes of strand anchors. The stressing wedges are heat treated, chrome plated and designed for multiple uses.

Centralizers

Centralizers are placed over the strand anchor assembly to maintain the minimum required 0.5” distance between the assembled anchor bundle and the drill hole wall. Depending on the anchor type and orientation, there are a wide variety of centralizers available for every application. State drill hole size for ordering.

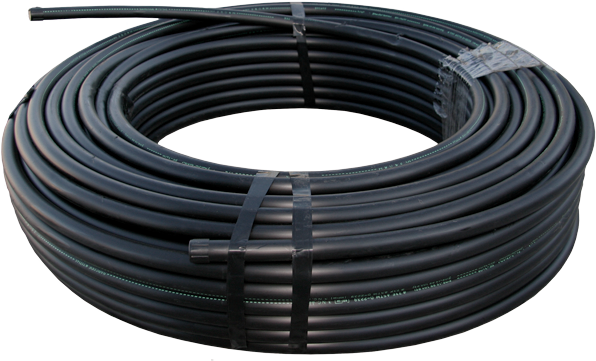

Heavy Duty Plastic Grout Tube

Available with a 1” nominal OD and 3/4” nominal ID. Furnished in product lengths or in rolls.

Post-Grout Tube

Williams will provide post-grout tubes for anchors bonded in weak rock or soil upon request. Williams supplies flexible Post-Grout Tube with bursting strengths of 1000 psi, as well as PVC Post-Grout Tube with bursting strengths of 900 psi. The Post-Grout Tube length and valve placement are adjustable and can be specified at the time of order. Drill hole diameter should be a 1” minimum clearance to accommodate Post-Grout Tube.

Corrosion Inhibiting Grease or Gel

Williams corrosion inhibiting compounds can be placed in the free stressing areas, in the end caps, and trumpet areas. Each are of an organic compound with either a grease or gel base. They provide the appropriate polar moisture displacement and have corrosion inhibiting additives with self-healing properties. They can be pumped or applied manually. Corrosion inhibiting compounds stay permanently viscous, chemically stable and non-reactive with the prestressing steel, duct materials or grout. Both compounds meet PTI standards for Corrosion Inhibiting Coating.

Spacers

Strand spacers are provided in the anchor bond zone to separate the strand and provide for the minimum required grout cover around each strand for corrosion protection and bond strength development. The strand spacers are normally located 1-2 feet above the bottom of the anchor and at the top of the bond zone. The intermediate strand spacers are typically placed at a distance of 5-10 feet, center to center along the bond zone between the top and bottom spacer.

Corrugated Duct

Williams utilizes corrugated duct that complies with the required wall thickness (0.060” nominal) as specified by the Post-Tensioning Institute’s Recommendations for Prestressed Rock and Soil Anchors.

Heat Shrink Tubing

Provides a corrosion protected seal when connecting or repairing smooth and corrugated segments.

Corrosion Protection Coatings

Optional coatings for steel end caps, bearing plates with trumpet and anchor heads are available for additional corrosion protection as required by the designer. Coating specifications are as follows.

Electro Zinc Plating: ASTM B633 (wedge plates)

Hot Dip Galvanizing: ASTMA123 (bearing plates/trumpets and steel end caps)

Epoxy Coating: ASTM A775 (bearing plates/trumpets and steel end caps