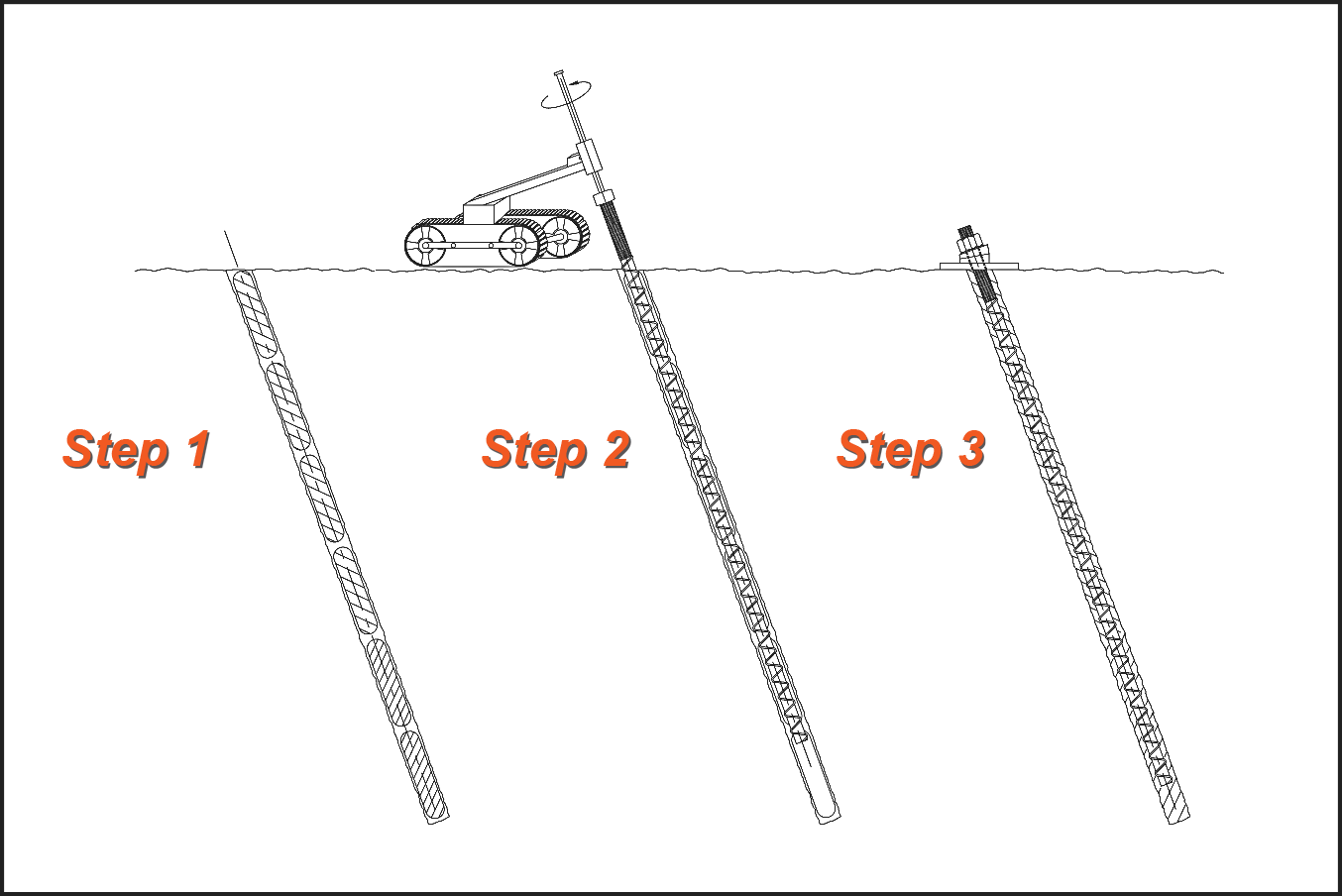

Resin Anchor Installation

Step 1

For Pre-Tensioned bolts, insert the necessary resin cartridges into the drill hole, by placing the fast-setting cartridges in first and the slow-setting cartridges last. Do not allow cartridges to free fall to bottom of hole.

Step 2

Push bolt into hole (rotating at this time is optional). When bolt is completely inserted into the hole, rotate 40-60 revolutions (approximately 10-15 seconds). Caution should be taken to avoid under-spinning or over-spinning.

Step 3

Install bearing plate, washer and hex nut. Complete pre-tensioning before slow-setting cartridges gel by using a hydraulic jack or torque wrench depending on design requirements. Installation is complete when slow-setting resin has hardened. Special accessories used for bolt angle adjustment are available here.

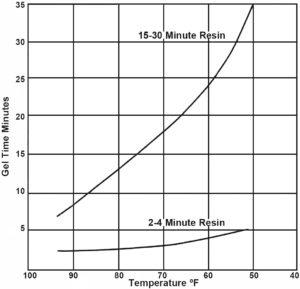

Gel Time

Two gel times are offered for varied conditions. The standard 2-4 minute gel time meets most requirements. However, for special conditions, where installations are difficult or full length anchored tensioned bolts are used, a 15-30 minute gel time is available. Gel times are standardized at 55-60º F. The effect of temperature on gel time is shown on the left. Temperatures below 35º F will significantly slow down set times. Call your Williams Representative for special fast set resins.

Compressive Strength

90% of Compressive Strength should be reached in 6 times gel time at 75ºF

Caution & Safety

This product is intended for industrial use only. Avoid contact with eyes and prolonged contact with skin. Wear safety glasses when handling or installing. If contact occurs, wash eyes or skin with water for 15 minutes. In case of eye contact, obtain medical attention. Cartridges contain benzoyl peroxide, polyester resin, styrene and inert fillers. The relationship between hole dimensions, bolt size and the size and number of cartridges is critical to good performance. Your Williams representative will be glad to assist in determining the proper combinations for specific applications.

Storage

Resin cartridges should be stored in a cool, well-ventilated and dry area away from direct sunlight. High temperature conditions can reduce shelf life. Cartridges stored in extreme temperatures should be “normalized” at 50-70º F for at least two days prior to use to provide the expected gel time. Pallets should not be stacked. Stock rotation is recommended so the oldest stock is used first.