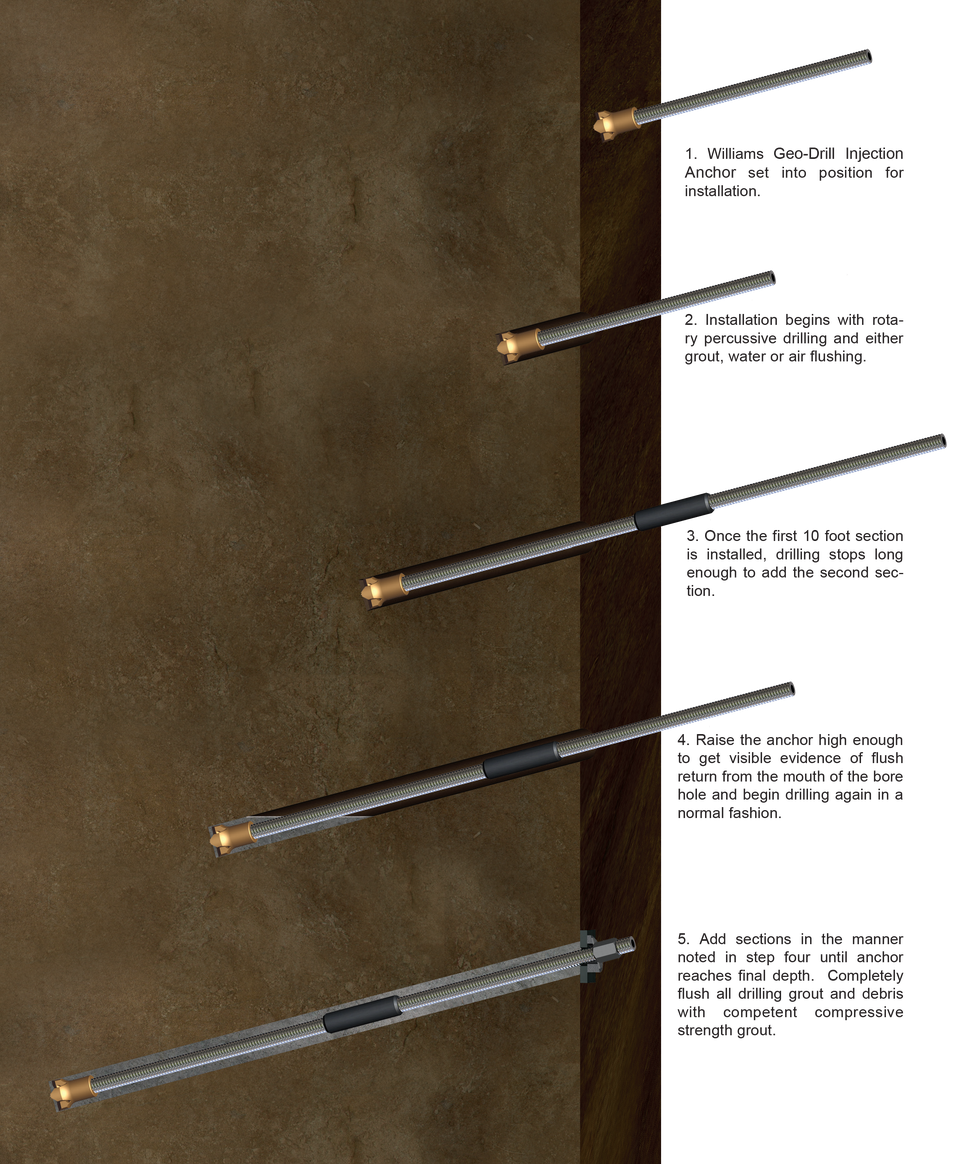

Geo-Drill Installation

The Williams Geo-Drill Injection Anchor System is optimally used in poor or very poor ground conditions ranging from inconsistent fill, boulders, rubble and weathered rock to sand and gravel. Generally the system is installed with rotary percussive drilling and continuous grouting. The thickness of grout can be varied depending on susceptibility of the borehole to collapse, however a grout mixture of 0.4 water to cement ratio is recommended in poor, collapsible soils to ensure a high enough density to support the annulus. In all cases, a final grout mixture of 0.40 w/c should be used for adequate in-situ structural capacity. Williams recommends mixing the grout in a colloidal (shear type) mixer, so once pumped, the fine grout particles are fully able to disperse into the small voids of the surrounding soil. This well mixed grout exits the side ports of the drill bit under pressure to flush and remove the softer parts of the soil while penetrating into the firmer material for increased bond capacity. Williams recommends to partially withdraw each fully drilled section up the drill mast prior to attaching new sections, this way the drilling can begin in a plunging type action to even further improve grout penetration. Utilizing proper drilling and grouting techniques is important as the system would generally fail between the soil/anchor interface, not the grout/anchor interface.

In all cases the hollow bar system should be drilled slow enough to ensure rotation through the soil as opposed to excessive percussion and feed pressure with limited rotation. Such practice will provide the formation of a true borehole with consistent grout cover. Grouting pressure should be sufficient to maintain circulation at all times with a small amount of grout return visible at the mouth of the borehole. In permeable ground, this can result in an increase in the grout column diameter by several inches. Consult a Williams Representative for more detailed information on what to expect based on your specific geotechnical report. Normal drilling rotation is in the range of 40 and 100 RPM.

Drill Rigs

The preferred method of installation for the Williams Geo-Drill Injection Anchor System is rotary percussion drilling, as this method offers good directional stability and high rates of production. Hand-held drill rigs can be used to install 32 mm (1-1/4”) bars. Hand-held equipment works best when used in conjunction with a jackleg or within a slideframe arrangement.

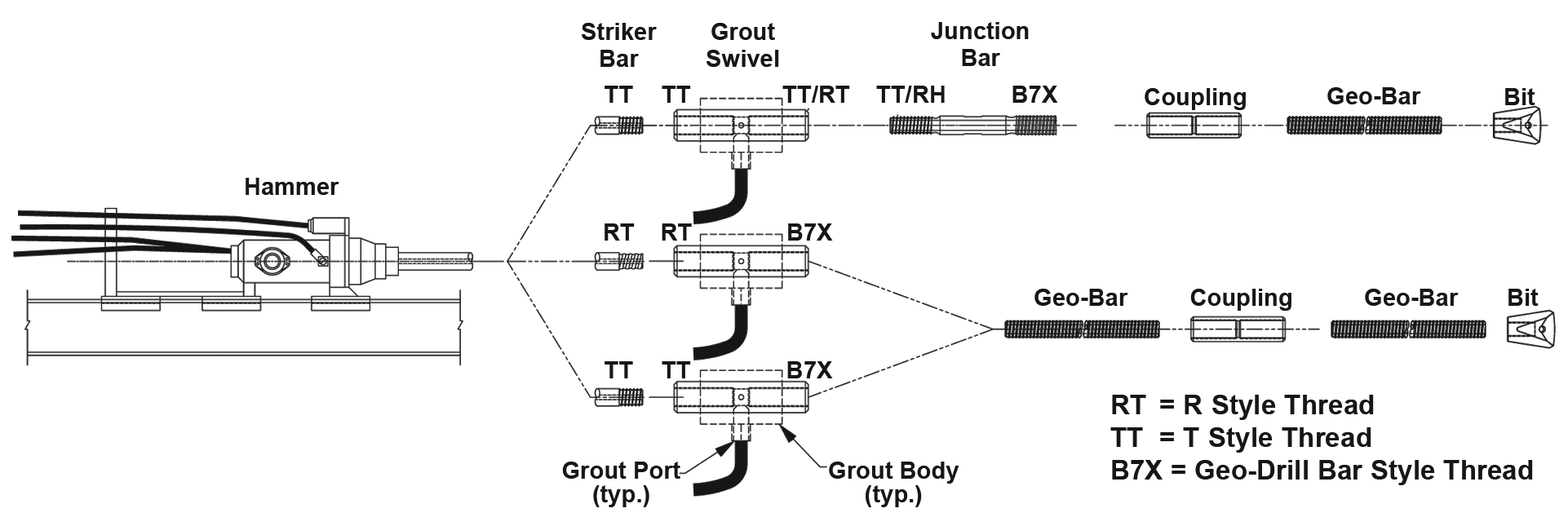

Grout-Swivel System for Rig Installation

For simultaneous drilling and grouting installations a grout-swivel system is required. The grout-swivel consists of a Grout Body and Grout Shank. The Grout Shank fits within the Grout Body and contains grout inlet ports. One end of the shank attaches to the striker bar while the other end attaches to the hollow bar anchor. The Grout Body contains an inlet pipe to allow grout to enter into the shank and down the hollow bar. The body remains stationary while the shank spins with the rotary action of the drill. To hold the body into position and prevent spinning with the rotary action of the drill, it is necessary to attach a locator frame from the body to the drifter.

We recommend water or grout flush (not air) be used with the grout-swivel system. In all cases, grease should be applied to the grout-swivel system prior to use.

Junction Bar

When using a grout shank with a T or R type thread, Williams recommends the use of a Junction Bar to transition between the Grout Shank and the Geo-Drill Bar. Coming out the anchor end of the Junction Bar would either be a Geo-Drill Coupling or Coupling Adapter. All disengagement during drilling to add sections or move to another anchor location would be done from below the Junction Bar and not at the Grout Shank, thus prolonging the life of the Grout Swivel.

Coupling Adapter

A Coupling Adapter is a machined and case hardened adapter, which is usually located just below the drill hammer and is used to connect the striker bar to the hollow bar. Sizes are available in any striker bar thread type to connect to any Hollow Injection Bar size. Generally a Coupling Adapter would be used in place of a grout-swivel during an air flush installation.