Spin-Lock Rock Anchor Installation

Step 1: Drilling

User Standard Rotary Percussion Equipment

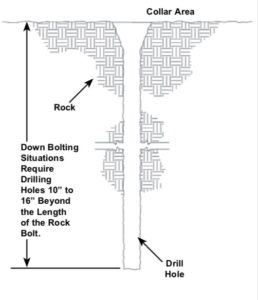

Care should be taken to insure an accurate diameter and a straight hole. The depth should be over drilled to allow any debris to fall to the bottom of the hole when the anchor is inserted. Clean the drill hole by blowing air to the full depth to remove debris. Efforts should be made to prepare the collar area with a flat surface and as perpendicular to the bolt axis as possible.

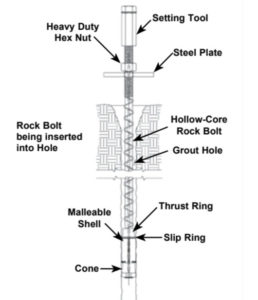

Step 2: Bolt Placement

Place the nut, washer, bevel washers (if required), and plate on the rock bolt and push the bolt into the hole to the correct embedment depth. If the bolt becomes stuck in the hole, attach a setting tool to the end of the bolt and drive it into the hole with a sledgehammer.

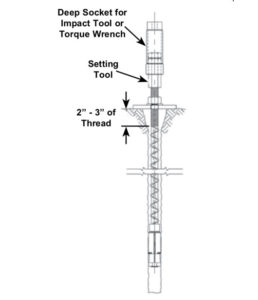

Step 3: Setting the Anchor

Install setting tool fully onto the exposed threaded end. Provide space between the setting tool and the hex nut. Initially torque the bolt to the required torque with an impact gun, pneumatic, or hydraulic torque wrench. This action migrates the cone into the shell, thus expanding the mechanical anchor into the rock. Final torque can be checked and adjusted with a manual or hydraulic torque wrench. Remove the setting tool by restraining the lower part while rotating it’s upper section until the setting tool is loose. Prepare collar area with fast setting grout sealer to ensure full bearing under the plate.

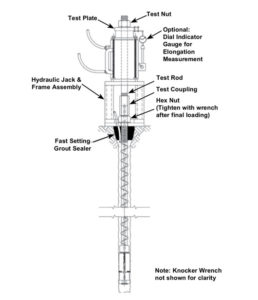

Step 4a: Testing the Anchor Bolt

Method A: Tensioning with a Test Jack

Place the jack and frame over the bolt and attach the test rod and couplings to the bolt. Attach the test nut and test plate over the test rod on top of the jack. Test the rock bolt by tensioning the jack to the required test load (usually half of the ultimate strength) but never to exceed the advertised yield strength of the anchor. Adjust the loading of the jack to the required final tension and lock in the final prestress load. This is done by tightening the rock bolt hex nut with a knocker wrench (through the frame opening) until a slight reduction is noticed on the jack gauge. The full prestress load will be transferred to the anchor bolt once the tension in the test jack has been released and test components removed.

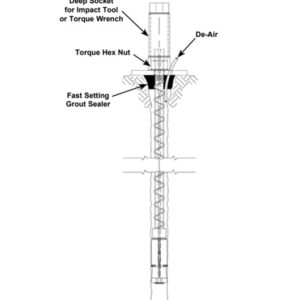

Step 4b: Testing the Anchor Bolt

Method B: Tensioning by Toque Tensioning

Place plate, bevel washers (if required), hardened washer, and hex nut on the rock bolt. Tension the bolt by torquing the hex nut with a torque wrench. For the recommended torque valve to obtain the advertised tensile working load, see the “Torque On Nut” column on the Spin-Lock Bolt charts. For other loads, see the torque tension graphs shown here. Please Note: The torque/tension relationship is not as accurate as direct tensioning with a hydraulic jack and should not be used where critical tension loads need to be verified. A high pressure lubricant should be used between all bearing components.

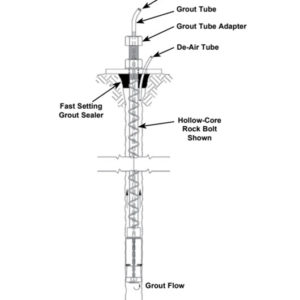

Step 5: Grouting the Anchor

Down Bolting

Always grout from the lowest gravitation point on the anchor bolt until a steady stream of pure grout is seen coming out around the bearing plate or grout tube, and/or from the de-air tube. For solid bolts, this means that a separate grout tube must be placed in the drill hole (through an opening in the bearing plate) as deep as possible before grouting. Long length solid bolts should have the grout tube attached to the bolt before inserting and setting the anchor. Down-grouting of Hollow Core Rock Bolts can be simply grouted through the hollow core by attaching a grout tube adapter to the outer end of the tensioned bolt and grouting. When the grouting is complete, all air and standing water has been removed from the drill hole by displacement and all cracks and voids in the anchor area are filled with cement grout.

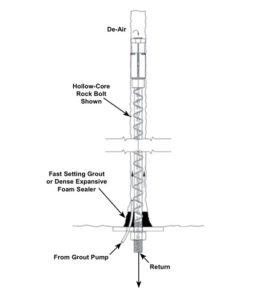

Up Bolting

Up-grouting of Hollow-Core Rock Bolts can be done by grouting through a short length grout tube extending just past the drill hole sealer in the collar area thus using the hollow core at the end of the rock bolt to de-air the hole. Up-grouting of solid rock bolts involves attaching a long length grout tube to the anchor (prior to insertion, setting, and tensioning) and grouting through a separate short length tube that extends past the sealer area thus allowing the rock bolt to de-air from the longer grout tube.

Williams offers a field installation advising service to aid contractors in the initial installation process of installing all types of anchor bolts. Contact your Williams sales representative for details.