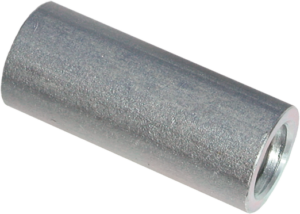

Sleeve Nuts

Sleeve Nuts are ideal when tensioning or adjusting of the tie rods is required internally at the bar to bar connection. The sleeve nut is less susceptible to bending than the turnbuckle and will develop 100% of the All-Thread-Bar published ultimate strength, however the turnbuckle allows the installer to see the thread engagement. Both components require right and left hand threads.

Sleeve Nut for 150 KSI All-Thread-Bar

| Bar Diameter |

Across Flats |

Overall Length |

Part Number |

|---|---|---|---|

| 1” (26 mm) |

2” (51 mm) |

6-1/2” (165 mm) |

R73-08SN |

| 1-1/4” (32 mm) |

2-1/2” (64 mm) |

8” (203 mm) |

R73-10SN |

| 1-3/8” (36 mm) |

2-3/4” (70 mm) |

9-1/2” (241 mm) |

R73-11SN |

| 1-3/4” (46 mm) |

3” (76 mm) |

13” (330 mm) |

R73-14SN |

| 2-1/4” (57 mm) |

3-1/2” (89 mm) |

14-1/4” (362 mm) |

R73-18SN |

| 2-1/2” (65 mm) |

4” (102 mm) |

16-1/2” (419 mm) |

R73-20SN |

| 3” * (75 mm) |

4-3/4” (121 mm) |

18-1/4” (464 mm) |

R74-24SN |

Sleeve Nut for Grade 75 All-Thread Rebar

| Bar Desig. & Nominal Dia. |

Across Flats |

Overall Length |

Part Number |

|---|---|---|---|

| #6 – 3/4” (19 mm) |

1-1/4” (32 mm) |

5-1/2” (140 mm) |

R63-06SN |

| #7 – 7/8” (22 mm) |

1-1/2” (38 mm) |

6-1/2” (165 mm) |

R63-07SN |

| #8 – 1” (25 mm) |

1-5/8” (41 mm) |

7-1/2” (191 mm) |

R63-08SN |

| #9 – 1-1/8” (29 mm) |

1-7/8” (48 mm) |

8-1/2” (216 mm) |

R63-09SN |

| #10 – 1-1/4” (32 mm) |

2-1/4” (57 mm) |

9-1/4” (235 mm) |

R63-10SN |

| #11 – 1-3/8” (36 mm) |

2-3/8” (60 mm) |

10” (254 mm) |

R63-11SN |

| #14 – 1-3/4” (43 mm) |

3” (76 mm) |

12” (305 mm) |

R63-14SN |

| #18 – 2-1/4” (57 mm) |

3-1/2” (89 mm) |

13-1/2” (343 mm) |

R63-18SN |

| #20 – 2-1/2” (64 mm) |

4” (102 mm) |

14-1/2” (368 mm) |

R63-20SN |

| #24 – 3” (76 mm) |

4-1/2” (114 mm) |

16” (406 mm) |

R64-24SN |

| #28 – 3-1/2” (89 mm) |

5-1/2” (140 mm) |

18” (457 mm) |

R64-28SN |

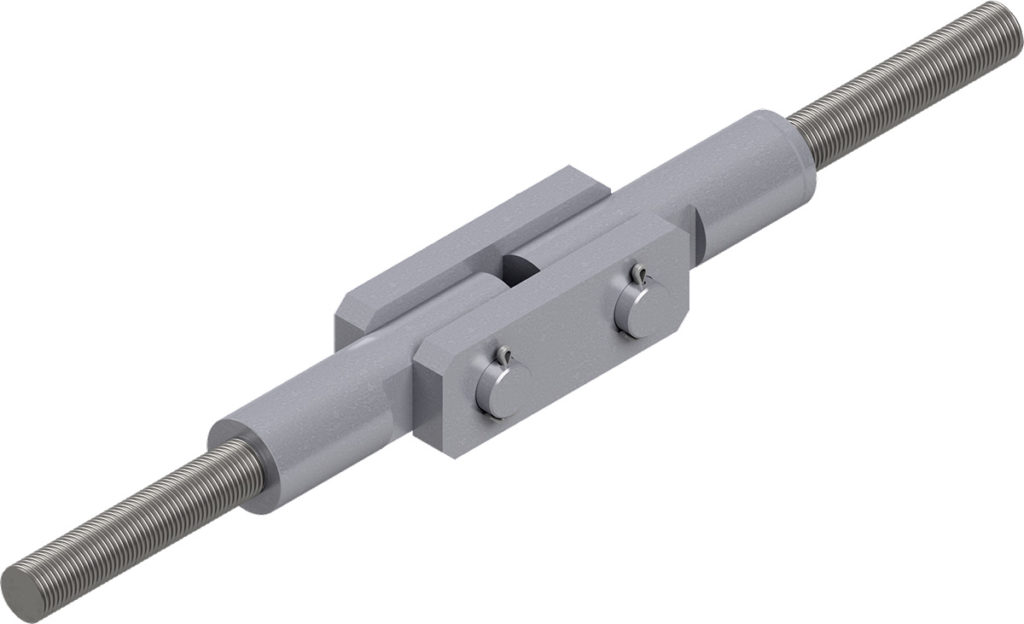

Turnbuckles

Turnbuckles are ideal when tensioning or adjusting of the tie rods is required internally at the bar to bar connection. he sleeve nut is less susceptible to bending than the turnbuckle, however the turnbuckle allows the installer to see the thread engagement. Both components require right and lefthand threads.

Turnbuckle for 150 KSI All-Thread-Bar

| Bar Diameter |

Overall Length |

Working Load |

Part Number |

|---|---|---|---|

| 1” (26 mm) |

17-1/2” (445 mm) |

26 kips (116 kN) |

CTB40K08 |

| 1-1/4” (32 mm) |

17-1/2” (445 mm) |

37 kips (165 kN) |

CTB50K10 |

| 1-3/8” (36 mm) |

19-5/8” (498 mm) |

48 kips (214 kN) |

CTB54K11 |

| 1-3/4” (46 mm) |

22-1/2” (572 mm) |

79.4 kips (353 kN) |

CTB65K14 |

| 2-1/4” (57 mm) |

22-1/2” (572 mm) |

122 kips (544 kN) |

CTB87K18 |

| 2-1/2” (65 mm) |

18” (457 mm) |

168 kips (746 kN) |

CTB88K20 |

| 3” * (75 mm) |

22-1/2” (572 mm) |

234 kips (1040 kN) |

CTB98K24 |

Turnbuckle for Grade 75 All-Thread Rebar

| Bar Desig. & Nominal Dia. |

Overall Length |

Working Load |

Part Number |

|---|---|---|---|

| #6 – 3/4” (19 mm) |

8-7/8” (225 mm) |

9.3 kips (41 kN) |

CTB21G06 |

| #7 – 7/8” (22 mm) |

9-1/8” (232 mm) |

11.6 kips (52 kN) |

CTB26G07 |

| #8 – 1” (25 mm) |

15-1/8” (384 mm) |

15.2 kips (68 kN) |

CTB30G08 |

| #9 – 1-1/8” (29 mm) |

15-3/4” (400 mm) |

21 kips (93 kN) |

CTB36G09 |

| #10 – 1-1/4” (32 mm) |

17-1/2” (445 mm) |

26 kips (116 kN) |

CTB40G10 |

| #11 – 1-3/8” (36 mm) |

17-1/2” (445 mm) |

37 kips (165 kN) |

CTB46G11 |

| #14 – 1-3/4” (43 mm) |

12-5/8” (321 mm) |

48 kips (214 kN) |

CTB53G14 |

| #18 – 2-1/4” (57 mm) |

14-3/4” (375 mm) |

79.4 kips (353 kN) |

CTB67G18 |

| #20 – 2-1/2” (64 mm) |

22-1/2” (572 mm) |

100 kips (445 kN) |

CTB70G20 |

| #24 – 3” (76 mm) |

18” (457 mm) |

168 kips (746 kN) |

CTB88G24 |

| #28 – 3-1/2” (89 mm) |

22-1/2” (572 mm) |

234 kips (1040 kN) |

CTB98G28 |

Clevis

A clevis can be used when tie rods are designed for angle adjustment, or when access to the outer side of the sheet pile is difficult.Designers must provide the hole diameter required in the structural steel to allow for proper sizing of the clevis pin.Pin diameters are available from 3/4” through 4-1/4”diameter.

Clevis for 150 KSI All-Thread-Bar

| Bar Diameter |

Overall Length |

Working Load |

Part Number |

|---|---|---|---|

| 1” (26 mm) |

11-3/4” (298 mm) |

37.5 kips (167 kN) |

CL5K08 |

| 1-1/4” (32 mm) |

11-3/4” (298 mm) |

37.5 kips (167 kN) |

CL5K10 |

| 1-3/8” (36 mm) |

13-3/4” (349 mm) |

54 kips (240 kN) |

CL6K11 |

| 1-3/4” (46 mm) |

15-1/2” (394 mm) |

68.5 kips (305 kN) |

CL7K14 |

| 2-1/4” (57 mm) |

18-1/8” (460 mm) |

135 kips (601 kN) |

CL8K18 |

| 2-1/2” (65 mm) |

18-1/8” (460 mm) |

135 kips (601 kN) |

CL8K20 |

| 3” * (75 mm) |

18-1/8” (460 mm) |

135 kips (601 kN) |

CL8K24 |

Clevis for Grade 75 All-Thread Rebar

| Bar Desig. & Nominal Dia. |

Overall Length |

Working Load |

Part Number |

|---|---|---|---|

| #6 – 3/4” (19 mm) |

7-7/8” (200 mm) |

15 kips (67 kN) |

CL3G06 |

| #7 – 7/8” (22 mm) |

7-7/8” (200 mm) |

15 kips (67 kN) |

CL3G07 |

| #8 – 1” (25 mm) |

9-5/8” (244 mm) |

21 kips (93 kN) |

CL4G08 |

| #9 – 1-1/8” (29 mm) |

9-5/8” (244 mm) |

21 kips (93 kN) |

CL4G09 |

| #10 – 1-1/4” (32 mm) |

11-3/4” (298 mm) |

37.5 kips (167 kN) |

CL5G10 |

| #11 – 1-3/8” (36 mm) |

11-3/4” (298 mm) |

37.5 kips (167 kN) |

CL5G11 |

| #14 – 1-3/4” (43 mm) |

13-3/4” (349 mm) |

54 kips (240 kN) |

CL6G14 |

| #18 – 2-1/4” (57 mm) |

15-1/2” (394 mm) |

68.5 kips (305 kN) |

CL7G18 |

| #20 – 2-1/2” (64 mm) |

18-1/8” (460 mm) |

135 kips (601 kN) |

CL8G20 |

| #24 – 3” (76 mm) |

18-1/8” (460 mm) |

135 kips (601 kN) |

CL8G24 |

| #28 – 3-1/2” (89 mm) |

18-1/8” (460 mm) |

135 kips (601 kN) |

CL8G28 |

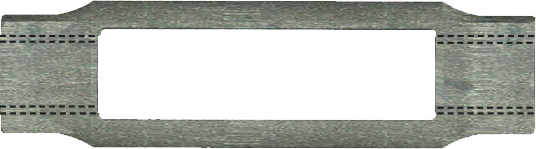

Stop Type Couplings

Williams mechanical couplers develop 100% of the All-Thread-Bar published ultimate strength.Couplers can be ordered Tap Thru or Stop-Type (ensuring 50:50 engagement). A coupler, as opposed to a turnbuckle or sleeve nut, is generally used when a splice is required and tensioning of the tie rod is easily accessible externally at the nut/plate interface.

R72 Stop-Type Coupling for 150 KSI All-Thread-Bar

| Bar Diameter |

Outside Diameter |

Overall Length |

Part Number |

|---|---|---|---|

| 1” (26 mm) |

1-3/4” (44 mm) |

4” (102 mm) |

R72-08 |

| 1-1/4” (32 mm) |

2-1/8” (54 mm) |

4-1/2” (114 mm) |

R72-10 |

| 1-3/8” (36 mm) |

2-3/8” (60 mm) |

5” (127 mm) |

R72-11 |

| 1-3/4” (46 mm) |

3” (76.2 mm) |

8-1/2” (216 mm) |

R72-14 |

| 2-1/4” (57 mm) |

3-1/2” (88.9 mm) |

8-1/2” (216 mm) |

R72-18 |

| 2-1/2” (65 mm) |

4-1/4” (108 mm) |

8-5/8” (219 mm) |

R72-20 |

| 3” (75 mm) |

5” (127 mm) |

11-7/8” (302 mm) |

R72-24 |

R62 Stop-Type Coupling for Grade 75 All-Thread Rebar

| Bar Desig. & Nominal Dia. |

Outside Diameter |

Overall Length |

Part Number |

|---|---|---|---|

| #6 – 3/4” (19 mm) |

1-1/4” (32 mm) |

3-1/2” (89 mm) |

R62-06 |

| #7 – 7/8” (22 mm) |

1-3/8” (35 mm) |

4” (102 mm) |

R62-07 |

| #8 – 1” (25 mm) |

1-5/8” (41 mm) |

4-1/2” (114 mm) |

R62-08 |

| #9 – 1-1/8” (29 mm) |

1-7/8” (48 mm) |

5” (127 mm) |

R62-09 |

| #10 – 1-1/4” (32 mm) |

2” (51 mm) |

5-1/2” (140 mm) |

R62-10 |

| #11 – 1-3/8” (36 mm) |

2-1/4” (57 mm) |

6” (152 mm) |

R62-11 |

| #14 – 1-3/4” (43 mm) |

2-7/8” (73 mm) |

6” (152 mm) |

R62-14 |

| #18 – 2-1/4” (57 mm) |

3-1/2” (89 mm) |

7-1/8” (181 mm) |

R62-18 |

| #20 – 2-1/2” (64 mm) |

4” (102 mm) |

8” (203 mm) |

R62-20 |

| #24 – 3” (76 mm) |

5” (127 mm) |

9-3/4” (248 mm) |

R62-24 |

| #28 – 3-1/2” (89 mm) |

5-1/2” (140 mm) |

12” (305 mm) |

R62-28 |

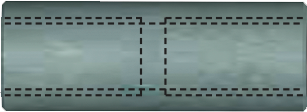

Articulating Coupler

Williams offers a specially designed articulating couplers for longer tie rod systems that allows the designer to mitigate soil backfill settlement concerns that potentially could cause failure of the tie rod in bending or shear. The articulating coupler allows freedom of vertical rotation on each side of the system as settlement occurs, and will develop 100% of the All-Thread-Bar published ultimate strength.