Mechanical Soil Anchor Installation

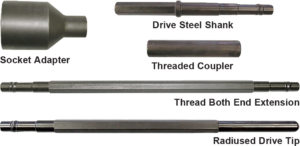

Drive Steel

Drive steel and accessories are available for all earth anchors in basic lengths of 3 feet and 6 feet. Multiple sections are coupled together to achieve the required depth of installation.

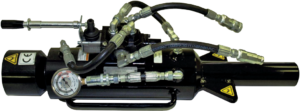

Load Locking Kits

For Manta Ray Anchors, the LL-1 is a 10-ton fast acting jack with an 8 inch stroke. The direct reading gauge and rod gripping jaws make load locking easy and quick. The base and jack are self-aligning to the actual installed angle of the anchor. It requires a hydraulic flow of 2 to 8 gallons per minute and a maximum pressure of 2,000 psi. A power supply is not included with this load-locking kit, it must be provided separately. Models GPU18-8 or GPU-2 are suitable. Consult your WFEC representative for more information.

Installation Methods

Vehicle Mounted Breakers or Compactors

Boom mounted demolition breakers are very effective for driving earth anchors. This method requires a special tool in the breaker to adapt to the drive steel. Skid steer loaders, backhoes or excavators work well. Breaker rated at between 250 to 500 foot-pound pavement breakers are best. Breaker tools are made for a variety of diameters. Consult your WFEC representative for more information.

Rock Drills

Top hammer or down-the-hole hammer rock drills are very effective for installation of soil anchors. For hard soil or weak rock installations, the drill can be used to drill a pilot hole. Williams can provide striker bar adapters for these types of drills. Rock drilling steel can also be modified to drive WFEC soil anchors.

Manual Installation

In some applications, earth anchors are driven into the soil with a 90 lb. pavement breaker and coupled drive steel. Pneumatic or hydraulic breakers are acceptable.