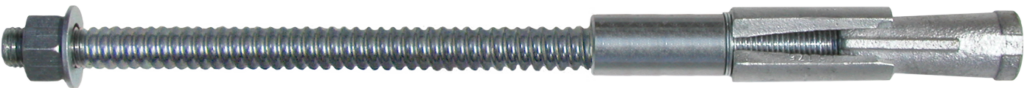

B7S Coil All-Thread Spin-Lock Rock Bolt

Williams B7S Coil All-Thread Spin-Lock Rock Anchor utilizes an ASTM A108 Grade C1045 steel which provides high strength capacity and has the advantage of utilizing a more common steel for greater availability.

B7S Structural Properties

| Diameter Range |

Yield Stress |

Ultimate Stress |

Elongation in 2” Gauge Length |

Reduction of Area |

|---|---|---|---|---|

| 1/2” to 1” (13 to 25 mm) |

92 KSI (634 MPa) |

120 KSI (827 MPa) |

11% min | 20% min |

| 1-1/8” and up (29 mm) |

81 KSI (558 MPa) |

105 KSI (723 MPa) |

11% min | 20% min |

Meets strength of ASTM A325

B7S Coil All-Thread Spin-Lock Rock Anchor

ASTM A108 Grade C1045

| Dia & Threads per In |

Max Recommended Design Load at 2:1 Safety Factor |

Yield Strength (fy) |

Ultimate Strength (fu) |

Drill Hole Diameter (1) |

Type Head Ass’y |

Torque (ft-lbs) | Part Number |

|

|---|---|---|---|---|---|---|---|---|

| To Expand Shell (2) |

On Nut for Tension (3) |

|||||||

| 1/2” – 13 (13 mm) |

8.45 kips (37.6 kN) |

13.0 kips (57.7 kN) |

16.9 kips (75.2 kN) |

1-1/4” – (32 mm) 1-5/8” – (41 mm) |

A 10 A 13 |

50 ft-lbs (70*) |

85 | B7S04A10 B7S04A13 |

| 5/8” – 11 (16 mm) |

13.3 kips (59.0 kN) |

20.3 kips (90.4 kN) |

26.5 kips (118 kN) |

1-1/4” – (32 mm) 1-5/8” – (41 mm) |

A 10 A 13 |

125 ft-lbs (250*) |

125 | B7S05A10 B7S05A13 |

| 3/4” – 10 (19 mm) |

20.0 kips (88.9 kN) |

30.6 kips (136 kN) |

40.0 kips (178 kN) |

1-3/4” – (44 mm) 1-3/4” – (44 mm) |

B 14 C 14 |

210 ft-lbs (250*) |

210 | B7S06B14 B7S06C14 |

| 7/8” – 9 (22 mm) |

27.5 kips (122 kN) |

42.1 kips (187 kN) |

55.0 kips (245 kN) |

2” – (51 mm) | B 16 | 390 ft-lbs (410*) |

390 | B7S07B16 |

| 1” – 8 (25 mm) |

35.4 kips (157 kN) |

54.3 kips (241 kN) |

70.8 kips (315 kN) |

2” – (51 mm) | B 16 | 500 ft-lbs (600*) |

550 | B7S08B16 |

| 1-1/8” – 7 (29 mm) |

38.8 kips (173 kN) |

59.9 kips (266 kN) |

77.6 kips (345 kN) |

2” – (51 mm) 2-1/4” – (57 mm) |

B 16 C 18 |

550 ft-lbs (600*) |

770 | B7S09B16 B7S09C18 |

| 1-1/4” – 7 (32 mm) |

50.8 kips (226 kN) |

78.5 kips (349 kN) |

102 kips (452 kN) |

2-1/4” – (57 mm) 2-1/2” – (64 mm) |

C 18 B 20 |

750 ft-lbs (1200*) |

1000 | B7S10C18 B7S10B20 |

| 1-1/2” – 6 (38 mm) |

73.8 kips (328 kN) |

114 kips (506 kN) |

148 kips (656 kN) |

3” – (76 mm) | B 24 | 1000 ft-lbs (1700*) |

Note (4) | B7S12B24 |

(*) Do not exceed these numbers

(1) Care should be taken to drill a straight and properly sized hole.

(2) A function of strata strength. More torque may be required on long anchors or in special rock conditions. Consult your Williams Representative.

(3) Torque value listed will achieve approximate load of 50% of the anchor ultimate strength, and is based on the torque tension curves here.

(4) Stress to desired tensile load using a hollow ram hydraulic jack. Consult your Williams Representative. – Inconsistencies in rock from site to site and even from hole to hole may affect anchor performances. Fissures, voids, seams, rock psi, drilling through clay or bentonite and direction of bedding planes are all possible variables. Should problems occur, consult Williams for troubleshooting.

– Spin-Locks come standard with 12” of threaded area. Other lengths available upon request.

– WILLIAMS reserves the right to ship full length or coupled units as necessary.

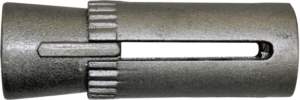

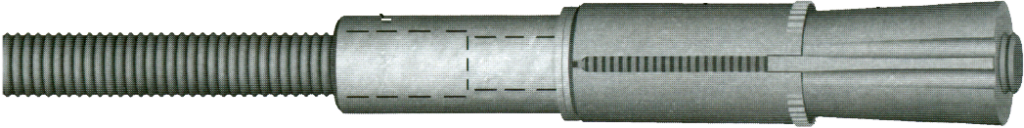

Head Assemblies

The Williams Spin-Lock anchor assembly gives full 300° bearing area. The smooth shell design allows for maximum shell to rock contact and eliminates “point of contact” created by serrated designs. The cone design supports the shell 300°, thereby eliminating any possible collapse of the shell under high load conditions. The thrust ring stop in front of the shell prevents any possible rebound of the expanded shell down the cone when subjected to nearby blasting. The Williams Spin-Lock anchor has been field proven on the world’s largest projects to far exceed in tension capacity any other mechanical anchor on the market.

| Head Assembly |

Drill Hole Diameter |

Bolt Diameter & Pitch |

Cone | Shell | Thrust Ring | Slip Rings |

Overall Assembly Length |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| Length | Part No. | Length | Part No. | Diameter | Thickness | |||||

| A10 | 1-1/4” (32 mm) |

1/2” – 13 NC (19 mm) |

1-7/8” (48 mm) |

SC-114-4 | 1-7/8” (48 mm) |

SS-114 | 1-1/8″ (29 mm) |

9/16″ (14 mm) |

1/16″ (1.6 mm) |

4-7/16” (112 mm) |

| 5/8” – 11 NC (16 mm) |

1-7/8” (48 mm) |

SC-114-5 | 1-7/8” (48 mm) |

SS-114 | 1-1/8″ (29 mm) |

9/16″ (14 mm) |

1/16″ (1.6 mm) |

4-7/16” (112 mm) |

||

| A13 | 1-5/8” (41 mm) |

1/2” – 13 NC (13 mm) |

1-7/8” (48 mm) |

SC-158-4 | 1-7/8” (48 mm) |

SS-158 | 1-1/2″ (38 mm) |

9/16″ (14 mm) |

1/16″ (1.6 mm) |

3-3/4” (95 mm) |

| 5/8” – 11 NC (16 mm) |

1-7/8” (48 mm) |

SC-158-5 | 1-7/8” (48 mm) |

SS-158 | 1-1/2″ (38 mm) |

9/16″ (14 mm) |

1/16″ (1.6 mm) |

3-3/4” (95 mm) |

||

| B14 | 1-3/4” (44 mm) |

3/4” – 10 NC (19 mm) |

3-3/4” (95 mm) |

LC-158-6 | 3-3/4” | LS-175 | 1-5/8” (41mm) |

15/16″ (24 mm) |

1/16″ (1.6 mm) |

8” (203 mm) |

| B16 | 2” (51 mm) |

7/8” – 9 NC (22 mm) |

2-1/2” (64 mm) |

LC-200-7 | 4” (102 mm) |

LS-200 | 1-7/8” (48 mm) |

15/16″ (24 mm) |

1/16″ (1.6 mm) |

7-3/8” (187 mm) |

| 1” – 8 NC (25 mm) |

2-1/2” (64 mm) |

LC-200-8 | 4” (102 mm) |

LS-200 | 1-7/8” (48 mm) |

15/16″ (24 mm) |

1/16″ (1.6 mm) |

7-3/8” (187 mm) |

||

| 1-1/8” – 7 NC (30 mm) |

2-1/2” (64 mm) |

LC-200-9 | 4” (102 mm) |

LS-200 | 1-7/8” (48 mm) |

1-1/8″ (29 mm) |

1/16″ (1.6 mm) |

7-1/2” (191 mm) |

||

| B20 | 2-1/2” (64 mm) |

1-1/4” – 7 NC (32 mm) |

4” (102 mm) |

LC-250 | 4” (102 mm) |

LS-250 | 2-1/8” (54 mm) |

1-1/4″ (32 mm) |

9/64″ (3.6 mm) |

9-1/2” (241 mm) |

| B24 | 3” (76 mm) |

1-1/2” – 6 NC (38 mm) |

5-1/2” (140 mm) |

LC-300 | 5-1/2” (140 mm) |

LS-300 | 2-3/4” (70 mm) |

1-1/2″ ( 38mm) |

5/32″ (4 mm) |

12-7/8” (325 mm) |

| C14 | 1-3/4” (44 mm) |

3/4” – 10 NC (19 mm) |

4-1/4” (108 mm) |

LCF-175-6 | 3-3/4” (95 mm) |

LS-175 | 1-5/8″ (41 mm) |

3/4″ (19 mm) |

1/16″ (1.6 mm) |

9” (229 mm) |

| 7/8” – 9 NC (22 mm) |

4-1/4” (108 mm) |

LCF-175-7 | 3-3/4” (95 mm) |

LS-175 | 1-5/8″ (41 mm) |

1″ (25 mm) |

1/16″ (1.6 mm) |

9-3/16” (233 mm) |

||

| C18 | 2-1/4” (57 mm) |

1-1/8” – 7 NC (30 mm) |

4-7/8” (124 mm) |

LCF-225-9 | 4” (102 mm) |

LS-225 | 2” (51 mm) |

1-1/4″ (32 mm) |

1/16″ (1.6 mm) |

10” (254 mm) |

| 1-1/4” – 7 NC (32 mm) |

4-7/8” (124 mm) |

LCF-225-10 | 4” (102 mm) |

LS-225 | 2” (51 mm) |

1-3/8″ (35 mm) |

1/16″ (1.6 mm) |

10-1/4” (260 mm) |

||

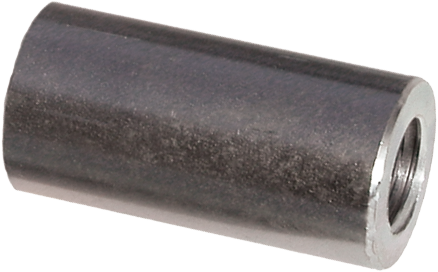

Coupled Head Assemblies

Williams can manufacture Spin-Lock Anchor systems with the use of a transition coupling, which allows the anchor to be designed with a continuously workable thread-form. This is advantageous when the anchor length may need to be adjusted in the field due to variable site conditions. The transition coupling engages a continuously threaded U.N. bar into the head assembly and the All-Thread Bar (typically Grade 75 & Grade 80 All-Thread Rebar or 150 KSI All-Thread-Bar) is attached to the other end of the coupling.

C2T Stop-Type Couplings & C2D Flange Couplings

| Bar Diameter |

Outside Diameter |

Overall Length |

Stop-Type Part Number |

Flange Coupling | |

|---|---|---|---|---|---|

| Flange Size | Part Number | ||||

| 1/2” (13 mm) |

3/4” (19 mm) |

1-1/2” (38 mm) |

C2T-04 | 2” x 2” (51 x 51 mm) |

C2D-04 |

| 5/8” (16 mm) |

1” (25 mm) |

1-3/4” (45 mm) |

C2T-05 | 2” x 2” (51 x 51 mm) |

C2D-05 |

| 3/4” (19 mm) |

1-1/8” (29 mm) |

2” (51 mm) |

C2T-06 | 2” x 2” (51 x 51 mm) |

C2D-06 |

| 7/8” (22 mm) |

1-1/4” (32 mm) |

2-1/4” (57 mm) |

C2T-07 | 3” x 3” (76 x 76 mm) |

C2D-07 |

| 1” (25 mm) |

1-1/2” (38 mm) |

3” (76 mm) |

C2T-08 | 3” x 3” (76 x 76 mm) |

C2D-08 |

| 1-1/8” (29 mm) |

1-5/8” (41 mm) |

3-1/2” (89 mm) |

C2T-09 | 3” x 3” (76 x 76 mm) |

C2D-09 |

| 1-1/4” (32 mm) |

1-7/8” (48 mm) |

3-3/4” (95 mm) |

C2T-10 | 3” x 3” (76 x 76 mm) |

C2D-10 |

| 1-1/2” (38 mm) |

2-1/4” (57 mm) |

5” (127 mm) |

C2T-12 | 3” x 3” (76 x 76 mm) |

C2D-12 |

H1F Heavy Duty Hex Nuts

| Bar Diameter |

Across Flats |

Across Corners |

Thickness | Part Number |

|---|---|---|---|---|

| 1/2” (13 mm) |

7/8” (22 mm) |

1.0” (26 mm) |

31/64” (12 mm) |

H1F-04 |

| 5/8” (16 mm) |

1-1/16” (27 mm) |

1.2” (31 mm) |

39/64” (16 mm) |

H1F-05 |

| 3/4” (19 mm) |

1-1/4” (32 mm) |

1.4” (37 mm) |

47/64” (19 mm) |

H1F-06 |

| 7/8” (22 mm) |

1-7/16” (37 mm) |

1.7” (42 mm) |

55/64” (22 mm) |

H1F-07 |

| 1” (25 mm) |

1-5/8” (41 mm) |

1.9” (48 mm) |

63/64” (25 mm) |

H1F-08 |

| 1-1/8” (29 mm) |

1-13/16” (46 mm) |

2.1” (53 mm) |

1-7/64” (28 mm) |

H1F-09 |

| 1-1/4” (32 mm) |

2” (51 mm) |

2.3” (59 mm) |

1-7/32” (31 mm) |

H1F-10 |

| 1-1/2” (38 mm) |

2-3/8” (60 mm) |

2.7” (70 mm) |

1-15/32” (37 mm) |

H1F-12 |

R9F Hardened Washers

| Bar Diameter |

Outside Diameter |

Inside Diameter |

Thickness | Part Number |

|---|---|---|---|---|

| 1/2” (13 mm) |

1-1/16” (27 mm) |

17/32” (14 mm) |

9/64” (3.56 mm) |

R9F-04-436 |

| 5/8” (16 mm) |

1-5/16” (33 mm) |

11/16” (17 mm) |

9/64” (3.6 mm) |

R9F-05-436 |

| 3/4” (19 mm) |

1-7/16” (37 mm) |

13/16” (21 mm) |

9/64” (3.6 mm) |

R9F-06-436 |

| 7/8” (22 mm) |

1-3/4” (45 mm) |

15/16” (24 mm) |

5/32” (4 mm) |

R9F-07-436 |

| 1” (25 mm) |

2” (51 mm) |

1-1/16” (29 mm) |

5/32” (4 mm) |

R9F-08-436 |

| 1-1/8” (29 mm) |

2-1/4” (57 mm) |

1-3/16” (30 mm) |

5/32” (4 mm) |

R9F-09-436 |

| 1-1/4” (32 mm) |

2-1/2” (64 mm) |

1-3/8” (35 mm) |

5/32” (4 mm) |

R9F-10-436 |

| 1-1/2” (38 mm) |

3” (76 mm) |

1-5/8” (41 mm) |

5/32” (4 mm) |

R9F-12-436 |

R8M Beveled Washers

| Bar Diameter |

Degree of Bevel |

Outside Diameter |

Inside Diameter |

Maximum Thickness |

Minimum Thickness |

Part Number |

|---|---|---|---|---|---|---|

| 1/2” (13 mm) |

14° | 1-1/4” (32 mm) |

9/16” (14 mm) |

7/16” (11 mm) |

1/8” (3 mm) |

R8M-04 |

| 5/8” (16 mm) |

11° | 1-9/16” (40 mm) |

13/16” (21 mm) |

1/2” (13 mm) |

3/16” (5 mm) |

R8M-06 |

| 3/4” (19 mm) |

11° | 1-9/16” (40 mm) |

13/16” (21 mm) |

1/2” (13 mm) |

3/16” (5 mm) |

R8M-06 |

| 7/8” (22 mm) |

15° | 2-1/16” (52 mm) |

1” (25 mm) |

3/4” (19 mm) |

1/4” (6 mm) |

R8M-08S |

| 1” (25 mm) |

15° | 2-1/16” (52 mm) |

1” (25 mm) |

3/4” (19 mm) |

1/4” (6 mm) |

R8M-08S |

| 1-1/8” (29 mm) |

15° | 2-13/16” (71 mm) |

1-5/16” (33 mm) |

1” (25 mm) |

5/16” (8 mm) |

R8M-09S |

| 1-1/4” (32 mm) |

15° | 3-3/8” (86 mm) |

1-9/16” (40mm) |

1-15/64” (31 mm) |

3/8” (9.5 mm) |

R8M-12S |

| 1-1/2” (38 mm) |

15° | 3-1/2” (89 mm) |

1-3/4” (45 mm) |

1-1/4” (32mm) |

3/8” (9.5 mm) |

R8M-13S |

To achieve full strength of the nut, beveled washers must be used in conjunction with a hardened washer.