S-9 Undercut Concrete Anchor Data

Structural Properties

| Yield Stress |

Ultimate Stress |

Elongation in 20 Bar Dia. |

Reduction of Area |

Charpy at -40ᵒ F (-40ᵒ C) |

|---|---|---|---|---|

| 105 KSI (723 MPa) |

125 KSI (861 MPa) |

16% min | 50% min | 20 ft/lbs (27 Joules) |

S-9 Undercut Concrete Anchor

ASTM A193 Grade B7

| Diameter & Threads per Inch |

Yield Strength (fy) |

Ultimate Strength (fu) |

Drill Hole Diameter (1) |

Minimum Embedment (3000 PSI – f’c) (2) |

Minimum Embedment (6500 PSI – f’c) (2) |

Part Number |

|---|---|---|---|---|---|---|

| 3/8” – 16 (9.5 mm) |

8.14 kips (36.2 kN) |

9.69 kips (43.1 kN) |

7/8” (22 mm) |

5” (127 mm) |

4” (102 mm) |

S9T-03 |

| 1/2” – 13 (13 mm) |

14.9 kips (66.3 kN) |

17.7 kips (78.9 kN) |

7/8” (22 mm) |

8” (204 mm) |

6” (153 mm) |

S9T-04 |

| 5/8” – 11 (16 mm) |

23.7 kips (105 kN) |

28.2 kips (125 kN) |

1-1/8” (29 mm) |

10” (254 mm) |

8” (204 mm) |

S9T-05 |

| 3/4” – 10 (19 mm) |

35.1 kips (156 kN) |

41.8 kips (186 kN) |

1-1/8” (29 mm) |

13” (331 mm) |

10” (254 mm) |

S9T-06 |

| 1” – 8 (25 mm) |

63.6 kips (283 kN) |

75.8 kips (337 kN) |

1-5/8” (41 mm) |

19” (483 mm) |

15” (381 mm) |

S9T-08 |

| 1-1/4” – 7 (32 mm) |

102 kips (453 kN) |

121 kips (539 kN) |

2” (51 mm) |

26” (661 mm) |

20” (508 mm) |

S9T-10 |

| 1-1/2” – 6 (38 mm) |

148 kips (656 kN) |

176 kips (781 kN) |

2-1/2” (64 mm) |

33” (839 mm) |

25” (635 mm) |

S9T-12 |

(1) Care should be taken to drill a straight and properly sized hole.

(2) Full ultimate strength of anchor can be achieved at listed embedment depth, provided there are no edge or spacing effects on the anchor.

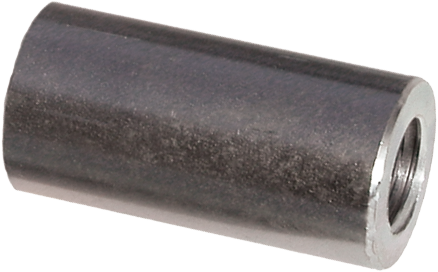

C2T Stop-Type Couplings & C2D Flange Couplings

| Bar Diameter |

Outside Diameter |

Overall Length |

Stop-Type Part Number |

Flange Coupling | |

|---|---|---|---|---|---|

| Flange Size | Part Number | ||||

| 3/8” (9.5 mm) |

3/4” (19 mm) |

1-1/2” (38 mm) |

C2T-03 | 2” x 2” (51 x 51 mm) |

C2D-03 |

| 1/2” (13 mm) |

3/4” (19 mm) |

1-1/2” (38 mm) |

C2T-04 | 2” x 2” (51 x 51 mm) |

C2D-04 |

| 5/8” (16 mm) |

1” (25 mm) |

1-3/4” (45 mm) |

C2T-05 | 2” x 2” (51 x 51 mm) |

C2D-05 |

| 3/4” (19 mm) |

1-1/8” (29 mm) |

2” (51 mm) |

C2T-06 | 2” x 2” (51 x 51 mm) |

C2D-06 |

| 1” (25 mm) |

1-1/2” (38 mm) |

3” (76 mm) |

C2T-08 | 3” x 3” (76 x 76 mm) |

C2D-08 |

| 1-1/4” (32 mm) |

1-7/8” (48 mm) |

3-3/4” (95 mm) |

C2T-10 | 3” x 3” (76 x 76 mm) |

C2D-10 |

| 1-1/2” (38 mm) |

2-1/4” (57 mm) |

5” (127 mm) |

C2T-12 | 3” x 3” (76 x 76 mm) |

C2D-12 |

H1F Heavy Duty Hex Nuts

| Bar Diameter |

Across Flats |

Across Corners |

Thickness | Part Number |

|---|---|---|---|---|

| 3/8” (9.5 mm) |

11/16” (18 mm) |

0.8” (20 mm) |

23/64” (9 mm) |

H1F-03 |

| 1/2” (13 mm) |

7/8” (22 mm) |

1.0” (26 mm) |

31/64” (12 mm) |

H1F-04 |

| 5/8” (16 mm) |

1-1/16” (27 mm) |

1.2” (31 mm) |

39/64” (16 mm) |

H1F-05 |

| 3/4” (19 mm) |

1-1/4” (32 mm) |

1.4” (37 mm) |

47/64” (19 mm) |

H1F-06 |

| 1” (25 mm) |

1-5/8” (41 mm) |

1.9” (48 mm) |

63/64” (25 mm) |

H1F-08 |

| 1-1/4” (32 mm) |

2” (51 mm) |

2.3” (59 mm) |

1-7/32” (31 mm) |

H1F-10 |

| 1-1/2” (38 mm) |

2-3/8” (60 mm) |

2.7” (70 mm) |

1-15/32” (37 mm) |

H1F-12 |

R9F Hardened Washers

| Bar Diameter |

Outside Diameter |

Inside Diameter |

Thickness | Part Number |

|---|---|---|---|---|

| 3/8” (9.5 mm) |

1” (25 mm) |

7/16” (11 mm) |

5/64” (2 mm) |

R9F-03-436 |

| 1/2” (13 mm) |

1-1/16” (27 mm) |

17/32” (14 mm) |

9/64” (3.56 mm) |

R9F-04-436 |

| 5/8” (16 mm) |

1-5/16” (33 mm) |

11/16” (17 mm) |

9/64” (3.6 mm) |

R9F-05-436 |

| 3/4” (19 mm) |

1-7/16” (37 mm) |

13/16” (21 mm) |

9/64” (3.6 mm) |

R9F-06-436 |

| 1” (25 mm) |

2” (51 mm) |

1-1/16” (29 mm) |

5/32” (4 mm) |

R9F-08-436 |

| 1-1/4” (32 mm) |

2-1/2” (64 mm) |

1-3/8” (35 mm) |

5/32” (4 mm) |

R9F-10-436 |

| 1-1/2” (38 mm) |

3” (76 mm) |

1-5/8” (41 mm) |

5/32” (4 mm) |

R9F-12-436 |

R8M Beveled Washers

| Bar Diameter |

Degree of Bevel |

Outside Diameter |

Inside Diameter |

Maximum Thickness |

Minimum Thickness |

Part Number |

|---|---|---|---|---|---|---|

| 3/8” (9.5 mm) |

14° | 1-1/4” (32 mm) |

9/16” (14 mm) |

7/16” (11 mm) |

1/8” (3 mm) |

R8M-03 |

| 1/2” (13 mm) |

14° | 1-1/4” (32 mm) |

9/16” (14 mm) |

7/16” (11 mm) |

1/8” (3 mm) |

R8M-04 |

| 5/8” (16 mm) |

11° | 1-9/16” (40 mm) |

13/16” (21 mm) |

1/2” (13 mm) |

3/16” (5 mm) |

R8M-06 |

| 3/4” (19 mm) |

11° | 1-9/16” (40 mm) |

13/16” (21 mm) |

1/2” (13 mm) |

3/16” (5 mm) |

R8M-06 |

| 1” (25 mm) |

15° | 2-1/16” (52 mm) |

1” (25 mm) |

3/4” (19 mm) |

1/4” (6 mm) |

R8M-08S |

| 1-1/4” (32 mm) |

15° | 3-3/8” (86 mm) |

1-9/16” (40mm) |

1-15/64” (31 mm) |

3/8” (9.5 mm) |

R8M-12S |

| 1-1/2” (38 mm) |

15° | 3-1/2” (89 mm) |

1-3/4” (45 mm) |

1-1/4” (32mm) |

3/8” (9.5 mm) |

R8M-13S |

To achieve full strength of the nut, beveled washers must be used in conjunction with a hardened washer.