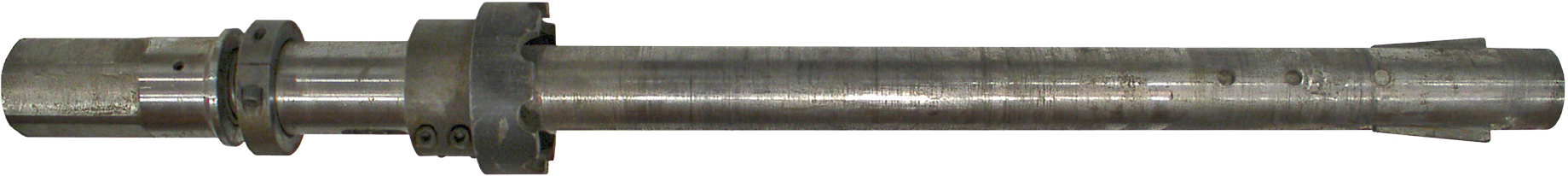

S9U Undercutting Tool

This tool is required for undercutting the holes to accommodate the S-9 Undercut Anchor. Designed to be attached to concrete coring equipment and apparatus with water flushing capabilities. Specifications available on request. Special length undercut tools can be manufactured upon request.

Typical Undercut Tools in Stock

| Bar Diameter |

Standard Embedment Range |

Part Number |

|---|---|---|

| 3/8” – 16 NC (9.5 mm) |

Up to 6-1/2” (165 mm) |

S9U-04H |

| 1/2” – 13 UNC (13 mm) |

Up to 8” (203 mm) |

S9U-04H |

| 5/8” – 11 UNC (16 mm) |

Up to 10” (254 mm) |

S9U-06H |

| 3/4” – 10 UNC (19 mm) |

Up to 12-1/4” (311 mm) |

S9U-06H |

| 1” – 8 UNC (25 mm) |

Up to 15-1/2” (394 mm) |

S9U-08H |

| 1-1/4” – 7 UNC (32 mm) |

Up to 21” (533 mm) |

S9U-10H |

| 1-1/2” – 6 NC (38 mm) |

Up to 27-1/2” (699 mm) |

S9U-12H |

Undercut Anchor Setting Chart

| Bar Diameter |

Cone Migration into Shell |

Distance per Revolution |

Revolutions Required to Set Cone to Shell |

|---|---|---|---|

| 3/8” – 16 UNC (9.5 mm) |

0.60” (15 mm) |

0.063” (1.59 mm) |

9 to 11 |

| 1/2” – 13 UNC (13 mm) |

0.72” (18 mm) |

0.077” (1.95 mm) |

9 to 11 |

| 5/8” – 11 UNC (16 mm) |

1.1 (28 mm) |

0.091” (2.31 mm) |

12 to 14 |

| 3/4” – 10 UNC (19 mm) |

1.2” (30 mm) |

0.100” (2.54 mm) |

11 to 13 |

| 1” – 8 UNC (25 mm) |

1.2” (30 mm) |

0.125” (3.18 mm) |

9 to 11 |

| 1-1/4” – 7 UNC (32 mm) |

1.6” (41 mm) |

0.143” (3.63 mm) |

11 to 13 |

| 1-1/2” – 6 NC (38 mm) |

3.0” (76 mm) |

0.167” (4.23 mm) |

18 to 20 |

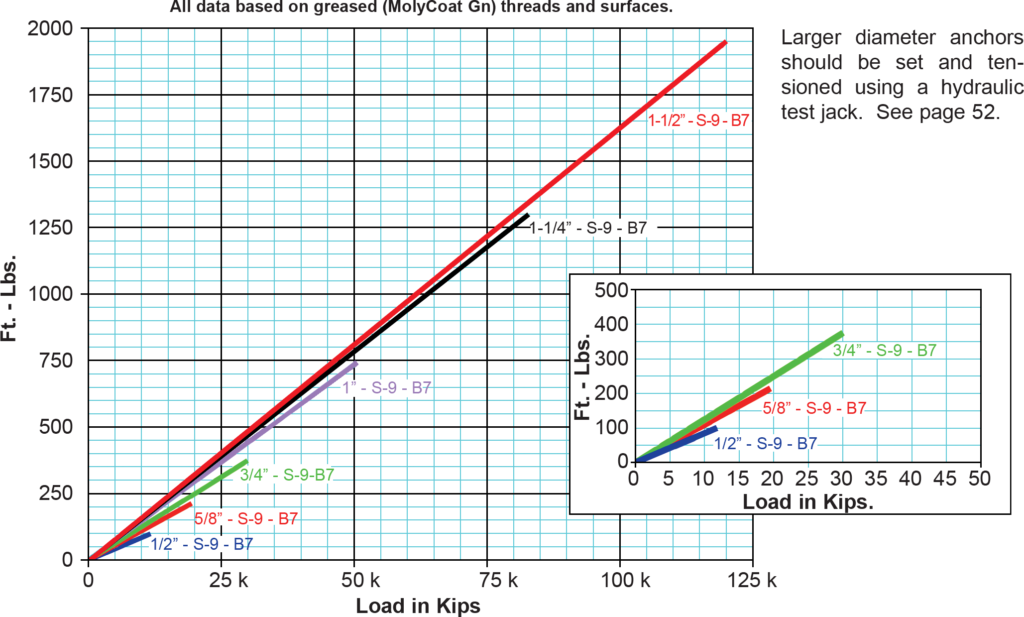

A193 Grade B7 Bar – Torque Tension Chart

All data based on greased (MolyKoat Gn) threads and surfaces. Torque tension relationships shown should be used as a guide. Actual tension can vary significantly, and should be verified in the field. If accurate tension is required, Williams recommends tensioning using a hydraulic ram.

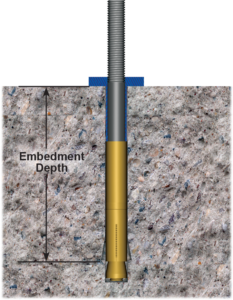

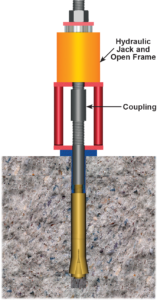

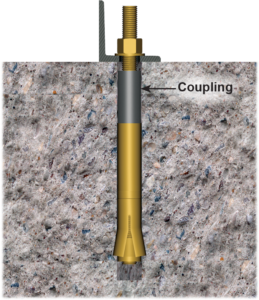

Installation

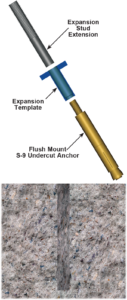

Flush Mount Anchor Installation

Williams also offers a flush mount S-9 Undercut Bearing Anchor that carries all the advantages of the standard S-9 , but adds the ease of installing in special conditions such as heavy machinery or large weldments. After hole is undercut, proceed as shown below in steps 1-5.

S-9 Flush Mount Undercut Concrete Anchor Data

| Anchor Size |

Minimum Embed. |

Offset | Coupling | |

|---|---|---|---|---|

| Dia | Length | |||

| 3/8” (9.5 mm) |

4-1/8” (105 mm) |

3/8” (10 mm) |

3/4” (19 mm) |

2-1/4” (57 mm) |

| 1/2” (13 mm) |

6” (152 mm) |

3/8” (10 mm) |

3/4” (19 mm) |

2-1/4” (57 mm) |

| 5/8” (16 mm) |

7-1/2” (191 mm) |

3/8” (10 mm) |

1” (25 mm) |

3” (76 mm) |

| 3/4” (19 mm) |

9-1/4” (235 mm) |

1/2” (13 mm) |

1-1/16” (27 mm) |

3” (76 mm) |

| 1” (25 mm) |

12-1/2” (318 mm) |

5/8” (16 mm) |

1-1/2” (38 mm) |

4-1/4” (108 mm) |

| 1-1/4” (32 mm) |

16” (406 mm) |

3/4” (19 mm) |

1-7/8” (48 mm) |

5-5/8” (143 mm) |

| 1-1/2” (38 mm) |

21-1/2” (546 mm) |

1” (25 mm) |

2-1/4” (57 mm) |

8-5/8” (219 mm) |

*For larger stainless diameters these dimensions may vary.