Epoxy Anchors Installation

Job-Site Preparation and Work Flow

These installation procedures provide a general idea of proper epoxy adhesive anchor installation. However, to achieve the desired results and capacities, it is important to follow the preparation and installation instructions as detailed in the most current Manufacturer’s Printed Installation Instruction (MPII) included in the product packaging.

Dual Cartridge Anchoring & Doweling Into Concrete

1. Drill hole to proper diameter and depth. Blow out dust from the bottom of the hole. Brush the hole with a nylon brush. Blow out dust again. The hole should be dry and clean of dust and debris.

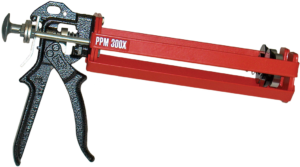

2. Insert cartridge into the gun with label side down. This allows you to see how much material is left in the cartridge.

3. Remove plastic band and black caps from the cartridge. Dispense a small amount of epoxy into a disposable container until you get an even flow of black and white material.

4. Thread nozzle onto cartridge, making sure the nozzle, and cartridge assembly are secure. Dispense enough epoxy into a disposable container, until the color becomes a consistent gray with no streaks.

5. Dispense the material from the bottom of the hole. Fill approximately 1/4 of the hole depth while slowly withdrawing the nozzle.

6. Insert the threaded bar or rebar to the bottom of the hole while turning bar into epoxy. The threaded bar or rebar should be free of dirt, grease, oil, or other foreign materials. Do not disturb or boltup until minimum boltup time has passed.