Fiber Glass Soil Nails

Williams Form fiberglass soil nails are ideally suited to be used for temporary shoring applications. Sireg Geotech, of Italy, has created a dependable flat bar fiberglass system that has been used on large projects in the United States, and now have teamed with Williams Form Engineering to provide local supply. The partnership between Williams and Sireg allows customers the benefit to have quick access to engineering support services offered by Williams.

The intended use of this product line is for temporary applications (<2 years duration). As such, the considerations documented in ACI 440.1R-06 are not pertinent to this application. Per ACI 440.1R-06, for permanent applications (sustained loads) there would be an advised environmental safety factor of 0.7 applied for degradation of the resin within the fiberglass strap as well as a sustained stress safety factor of 0.2. Since the intended use of this product is for temporary application, no degradation of the resin takes place in less than 2 years and no sustained stress losses need be accounted for as it is a short duration. An acceptable working/service load should not exceed 50% of the ultimate tensile strength of the tendon (equivalent to a reduction factor of 0.5).

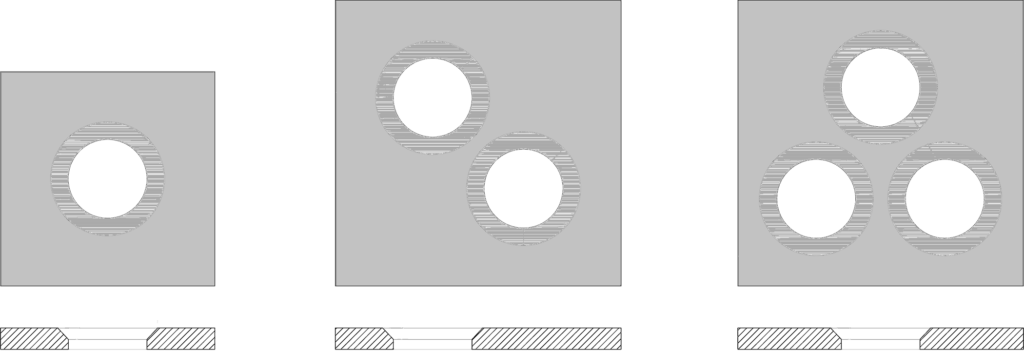

1-Durglass Soil Nail

2-Durglass Soil Nail

3-Durglass Soil Nail

Sireg 40mm x 9mm Geotech Durglass Soil Nails

| Durglass Soil Nail |

Nominal Area |

Weight ± 8% |

Ultimate Load Soil Nail |

Ultimate Load Blocking System |

Average Elastic Modulus |

Type of Spacer |

Part Number |

|---|---|---|---|---|---|---|---|

| 1-Durglass | 0.55 in² (355 mm²) |

0.46 lbs/ft (0.68 kg/m) |

65 kips (289 kN) |

33 kips (147 kN) |

6000 ksi (41 Gpa) |

Single | RFA1 |

| 2-Durglass | 1.11 in² (710 mm²) |

0.91 lbs/ft (1.36 kg/m) |

130 kips (578 kN) |

66 kips (294 kN) |

6000 ksi (41 Gpa) |

Double | RFA2 |

| 3-Durglass | 1.67 in² (1065 mm²) |

1.37 lbs/ft (2.04 kg/m) |

195 kips (867 kN) |

100 kips (445 kN) |

6000 ksi (41 Gpa) |

Triple | RFA3 |

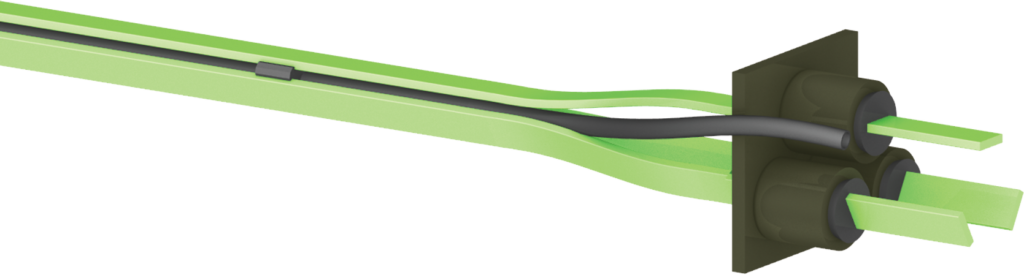

Long Lengths – No Splices

The continuous fiberglass flat bars come in rolls and can be cut to the length necessary for each individual nail. Also, by function of them being transported in rolls, there is an option to assemble in the field and have very long nails with no issues related to spontaneous length adjustments. The only fasteners used are those of the blocking system of the tendon anchorage.

Lightweight

The lightweight nature of the fiberglass bars lends to easy handling in the field. The soil nail elements can be very long and still require minimal lifting equipment. With a single fiberglass strap weighing a mere 0.454 lbs/ft, large quantities of this material can ship via flatbed, thus eliminating multiple shipments to project sites. The bulk of the weight in shipping comes from the steel bearing plates and wedge cups. The spacers and fiberglass wedges are non-steel and lightweight.

Removable

With urban development requirements of no permanent support of excavation steel tendons left in place for the upper 25 feet of excavation in some urban cities, the fiberglass product saves a great deal of time and money by not requiring anchor or nail removal. These fiberglass elements can simply be excavated through and buried with no harmful environmental side effects or costly damage to machinery.

Plastic Spacers

Blocking System

The Blocking system to be used with fiberglass soil nails is composed of a Steel Head Wedge Cup and Plastic Conical Wedges.

| Diameter | Length | Weight | Part Number |

|---|---|---|---|

| 3-1/4” (82 mm) |

3-3/8” (85 mm) |

4.5 lbs (2.1 kg) |

RFBS |

Steel Plates

| Durglass Soil Nail |

Number of Holes |

Length & Width |

Thickness | Part Number |

|---|---|---|---|---|

| 1-Durglass | 1 | 6” (150 mm) |

3/4” (19 mm) |

RFSP01 |

| 2-Durglass | 2 | 8” (200 mm) |

3/4” (19 mm) |

RFSP02 |

| 3-Durglass | 3 | 8” (200 mm) |

3/4” (19 mm) |

RFSP03 |