Types of Earth Anchors

Williams Form Engineering is known throughout the world as one of the leaders in the manufacturing of ground anchor systems. With over 80 years of experience we are able to provide product and/or information for virtually any ground anchor application, and if necessary supply on-site technical assistance. Williams manufactures or distributes anchors in all four primary groups of ground anchor systems available on the market today. The four primary groups of ground anchors are as shown:

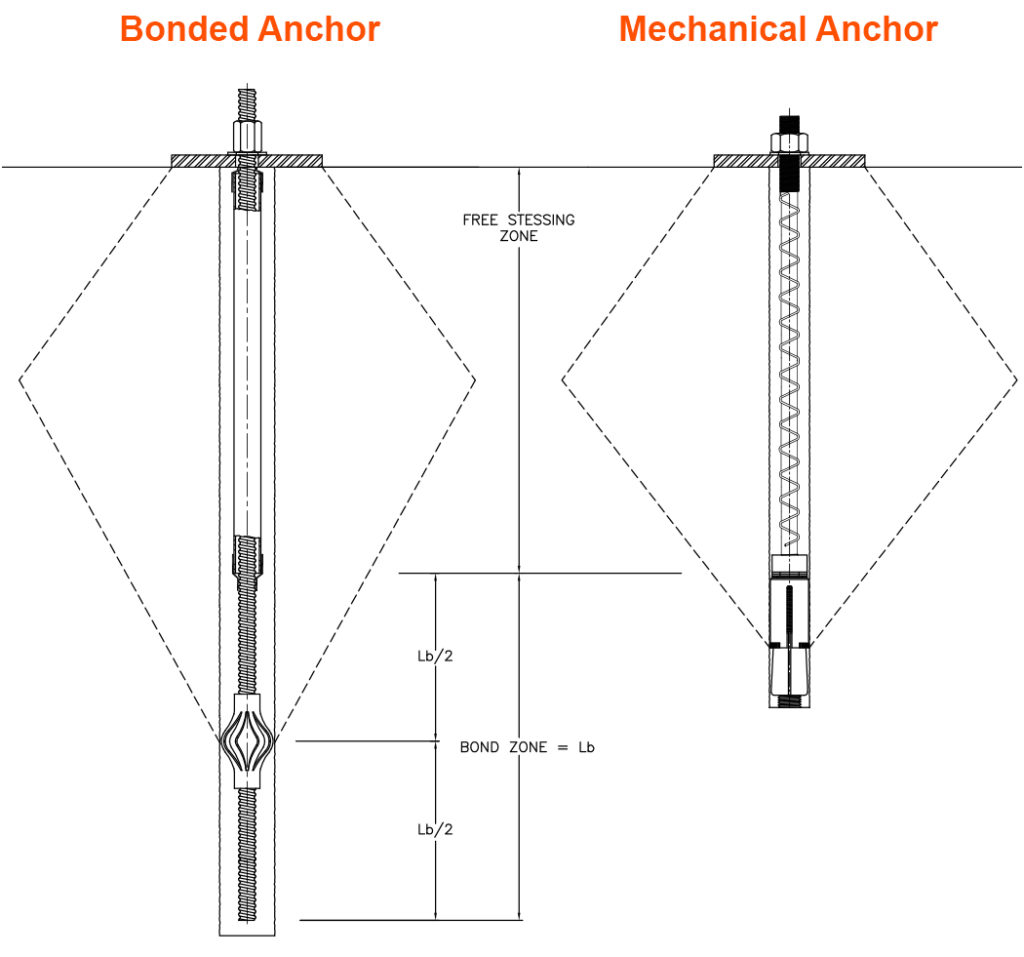

Cement Grout Bonded Anchors

Cement grout is used to develop a bond between the anchor and the soil or rock. Williams anchors can be made with several different types of steel grades.

Polyester Resin Anchors

Resin cartridges are used to develop anchorage between the anchor bar and the rock. Williams supplies All-Thread-Bars and threaded rebar for resin anchors. Resin anchors often are a fast and economical solution for temporary rock support.

Mechanical Rock Anchors

A mechanical head assembly with an expansion shell and cone is used to develop a friction lock between the rock and head assembly.

Mechanical Soil Anchors

A pivoting plate such as the one used with the Manta Ray soil anchor shown left, is driven to a specified depth and rotated 90° to develop anchorage in the soil.

Cement Grout Bonded Anchors

Advantages

1. Grout bonded anchors can be used in virtually all rock conditions and also in most soils.

2. The maximum working load with a single Williams bar anchor or multi-strand tendon can exceed 1,000 kips.

Disadvantages

1. The installer must wait for adequate compressive strength of the grout to be reached before prestressing the anchor.

2. A bond zone must be established, so deeper drilling is required to develop the design load in comparison to a mechanical anchor.

3. In weak rock or soils, a test program or sample borings should be used to determine drill hole diameter and anchor lengths.

Mechanical Rock Anchors

Advantages

1. No bond zone, so less drilling is necessary to develop the same shear cone as the bonded anchor system. Also, less grout is needed since there is less hole volume.

2. The installer can prestress and grout the anchor in the same day.

3. There is no cracking of the grout column, since the installer is prestressing the anchor before grouting.

4. The oversized drill hole provides for excellent grout coverage.

Disadvantages

1. The mechanical rock anchor should only be used in competent rock.

2. The maximum working load for Williams largest mechanical anchor, utilizing a 2:1 safety factor from the ultimate tensile steel capacity, is 180 kips.

Polyester Resin Anchors

Advantages

1. Prestressing can be accomplished within minutes of the installation.

2. Resin bonded anchor bolts are one of the most economical temporary rock anchor systems available.

3. Resin anchoring is successful in most rock types.

Disadvantages

1. Resin anchors are difficult to protect against corrosion. They require tight drill holes for propermixing of cartridges, resulting in only a thin resin cover. In addition, resin anchors cannot be centered in the drill hole, which allows the bolt to rest on the bottom or side of the hole. Resin is placed into the drill hole in a pre-measured amount which does not account for resin loss into rock seams and cracks. Loss of resin creates unprotected gaps along the anchor, essentially reducing the safety factor of the system.

2. Resin anchors with lengths over 25 feet are difficult to install because resin gel time often requires speedy installations. Couplings cannot be used with full column resin anchors because their outer diameter is too large relative to the drill hole diameter.

3. Water presence can greatly reduce the holding capacity of the anchor or cause the anchors to be susceptible to creep.

4. Temperature affects set and cure times of the resin.

Mechanical Soil Anchors

Advantages

1. Problems associated with drilling anchor holes are eliminated because the anchor is driven into the soil.

2. All anchors are tested during installation and provide immediate anchorage. Actual holding capacity is determined during pull testing.

3. Time and expense associated with mixing and dispensing grout is eliminated.

Disadvantages

1. The anchors are designed to hold no more than a 50 kip maximum working load. Holding capacity can be limited by the bearing strength of the soil.

2. Corrosion protection is limited.

3. Rocks or other obstructions in the installation path can prevent adequate embedment.