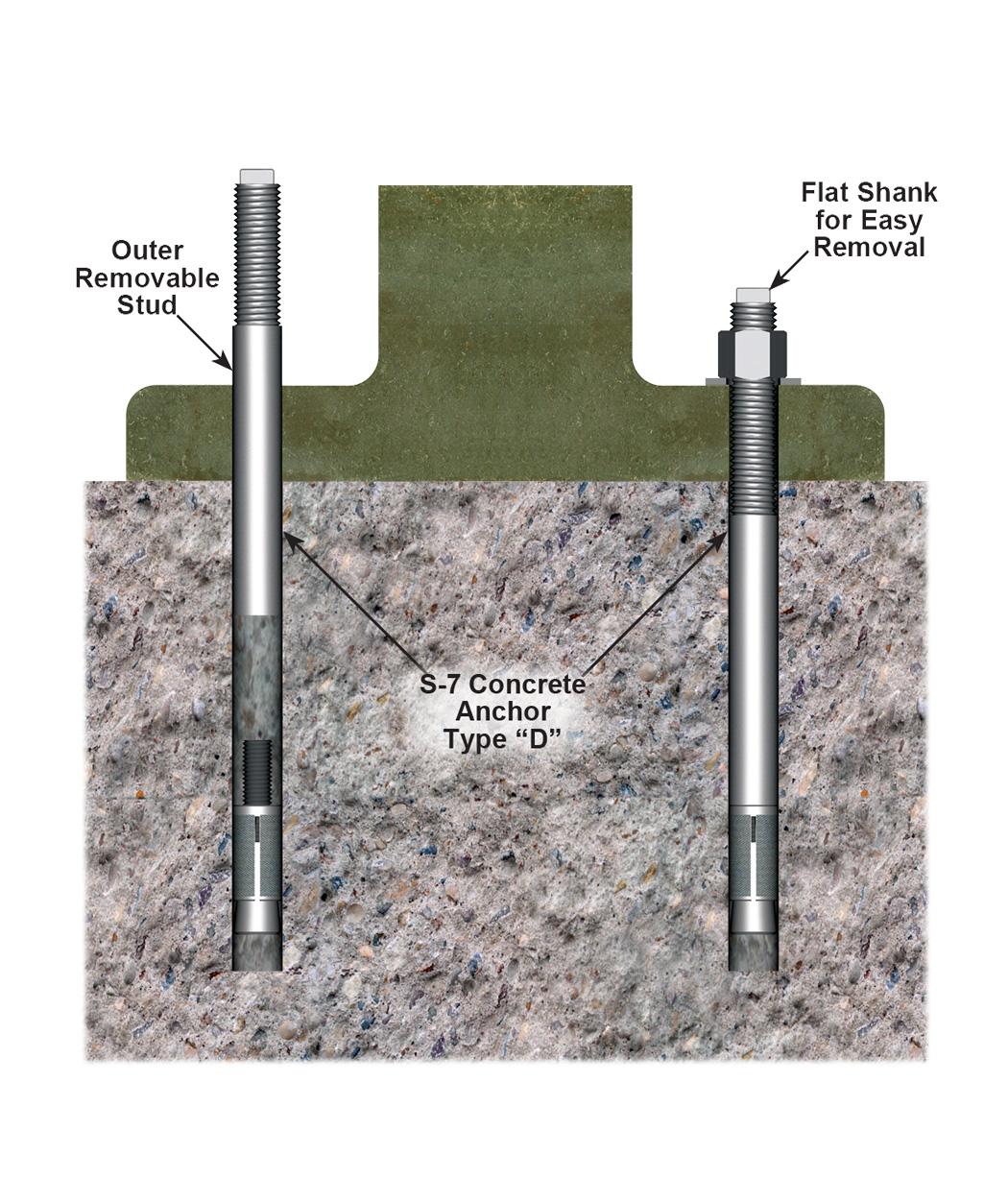

S-7 Concrete Anchors

The S-7 anchor consists of a reliable torque controlled expansion anchor assembly similar to the Spin-Lock, however the S-7 drill hole diameter is the same size as the anchor stud diameter. This non-grouted anchor system is easy for contractors to install and the fast setting procedure saves time and money on important anchor installations. S-7 anchors are ideal for conditions that do not require cement grout as a corrosion protection barrier and are generally specified as a multi-purpose product with re-usable capabilities. The head assembly boasts a full 300° bearing area. S-7 anchors come complete with outer hex nut and washer. Zinc plating for corrosion protection is standard up to 1” diameter bolts and optional on larger sizes. Anchors are also available in stainless up to 1” in diameter.

S-7 Reusable Concrete Anchor Advantages

- Smaller drill holes

- Removable outer stud for reuse

- Field proven expansion anchor

- Convenient patching after removal

- Prestressable

- Anchor outer studs & heads can be purchased separately

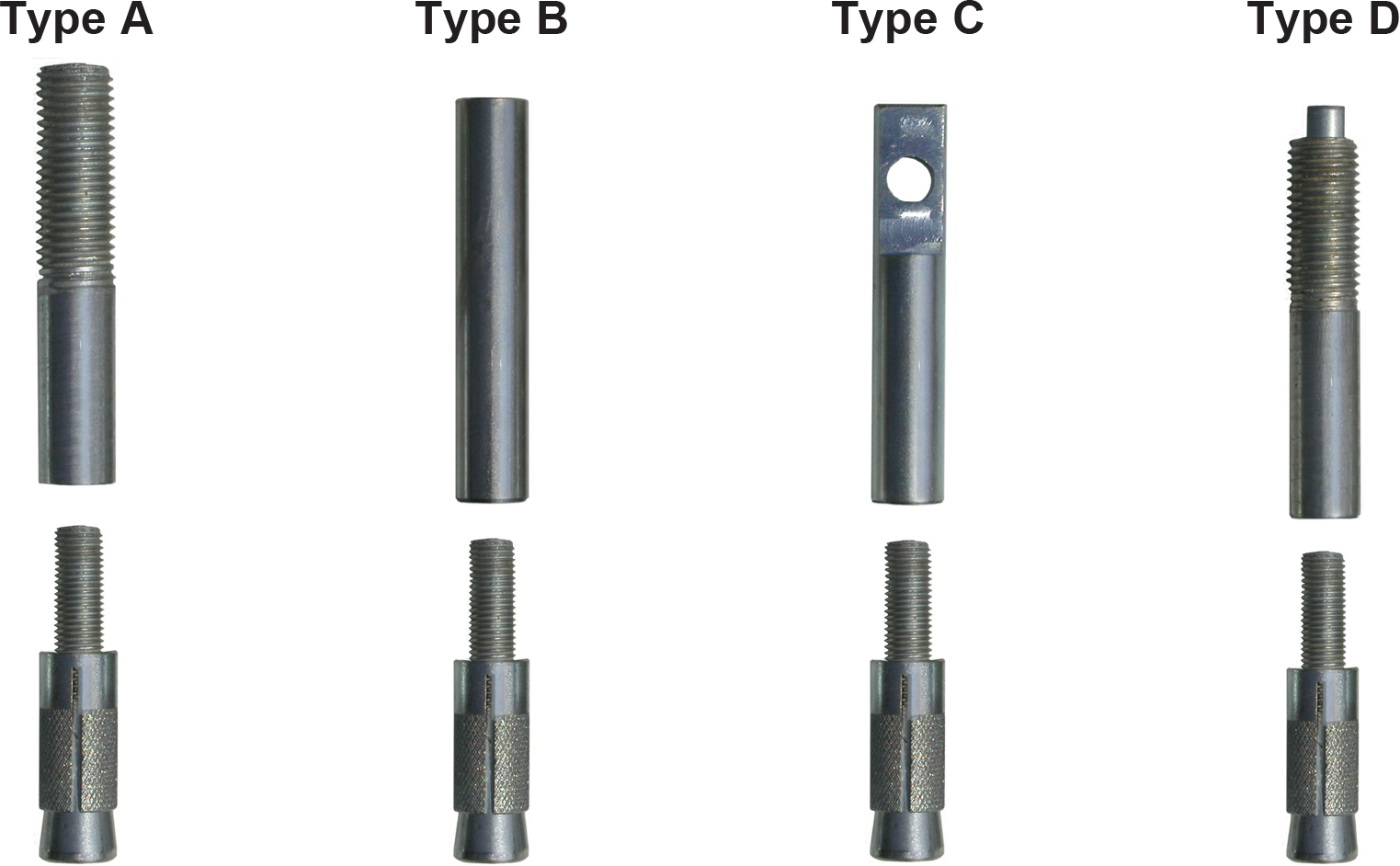

S-7 Reusable Concrete Anchor Stud Types

S-7 anchors are available with a variety of removable outer studs for special applications.

Type A – Typical for outer stud diameters over 1”.

Type B – For applications where a recessed, tapped hole is required. Type B anchors are usually flush with the concrete surface and installed with a special Williams setting tool.

Type C – For stringing cable or wire through the anchor end. This anchor is often used for wire hangers or guy type anchorages.

Type D – Typical for outer stud diameters of 1” or smaller. Outer stud end has flats that allow for easy anchor removal.

Applications

The S-7’s unique design allows the hole to be drilled and the bolt to be placed through an existing plate, tower base or machine base when required. In a temporary bolting situation, the outer portion of the bolt may be removed and dis-carded or reused once the anchor is no longer needed. Since it is unnecessary to pull out or burn off unwanted anchors, patching operations are quick and clean.

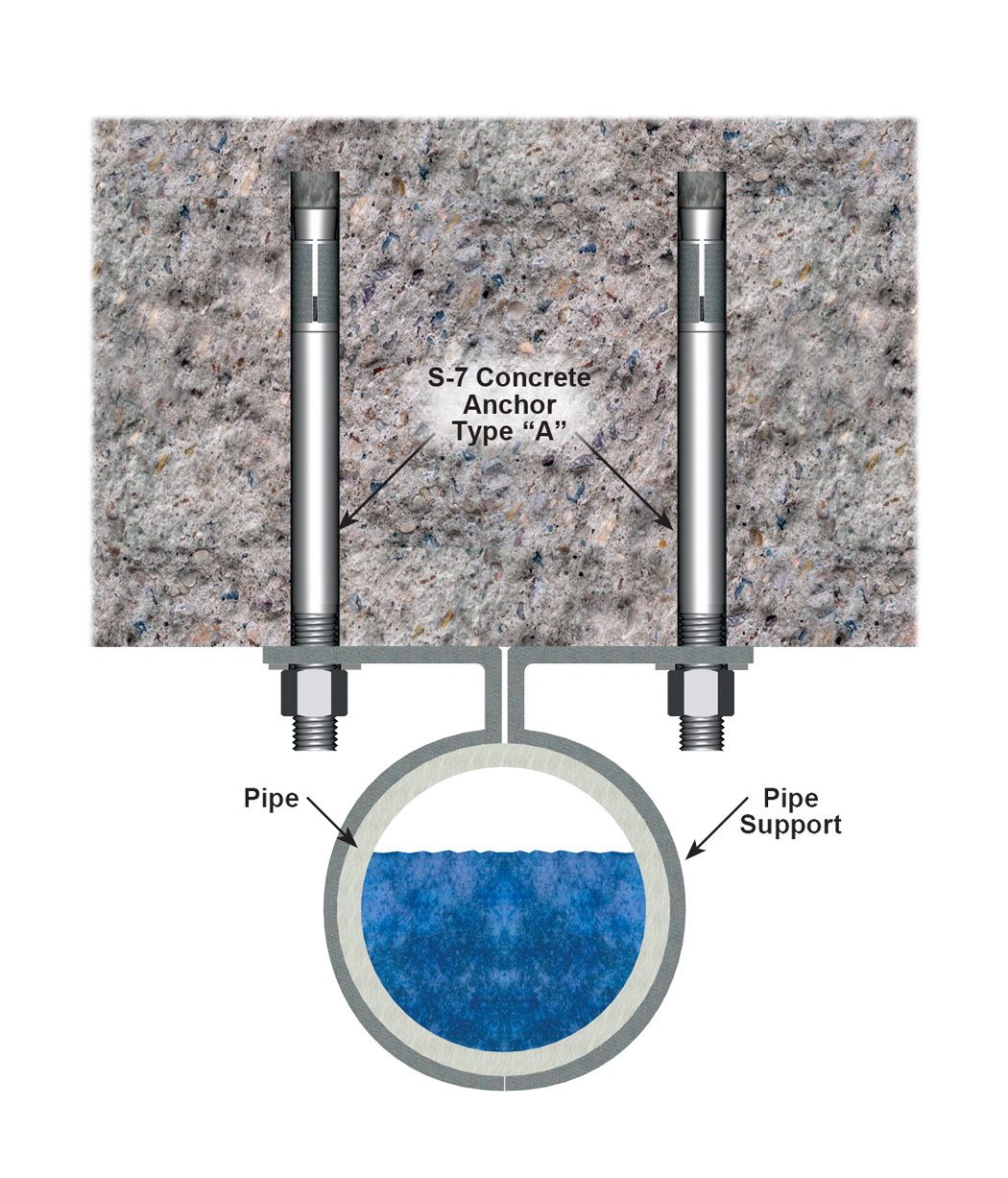

Pipe Supports or Electrical Tray Hangers

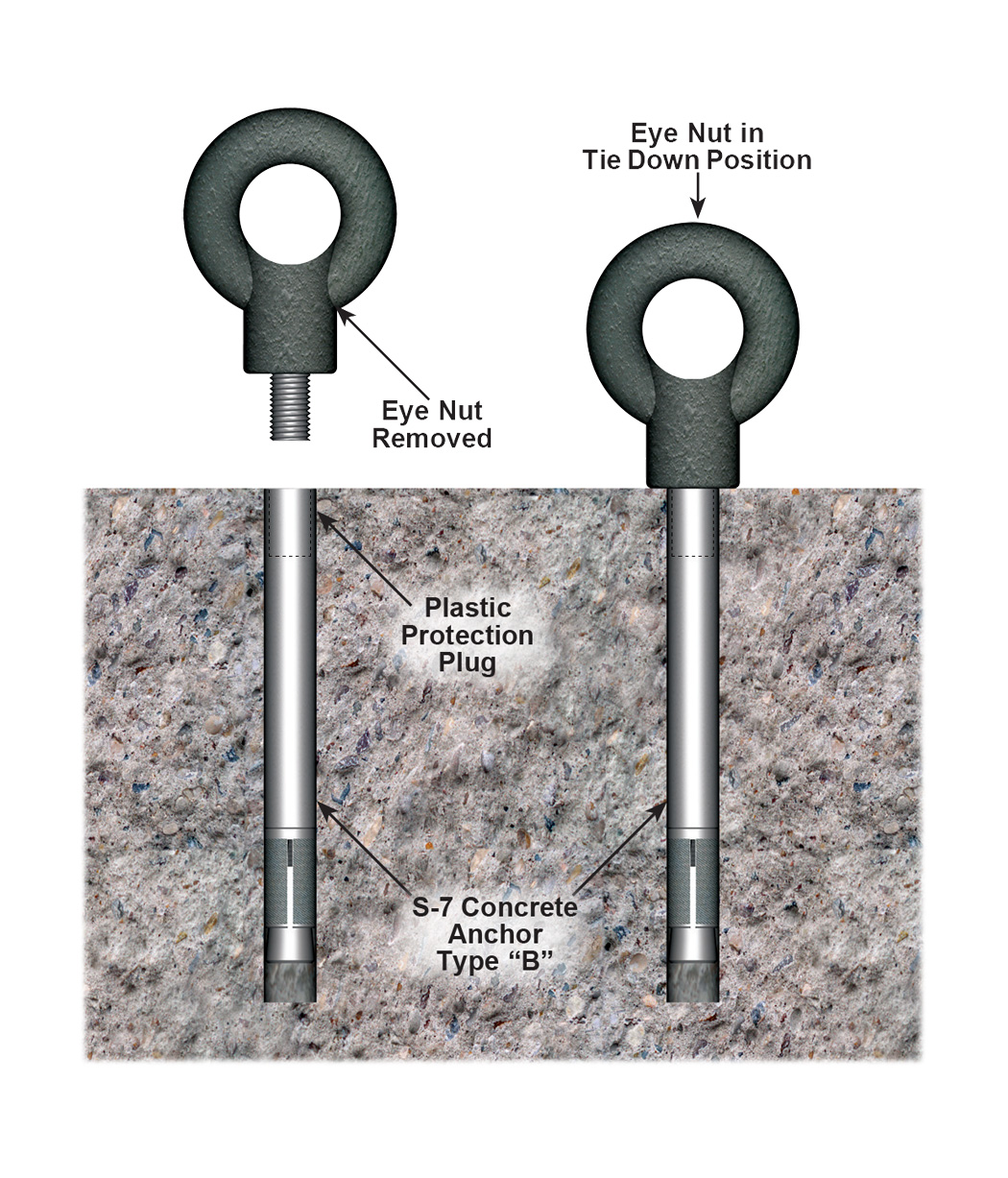

Temporary Tie Down Anchors for Aircraft & Inflatable Structure Covers

Removable Machinery Anchor

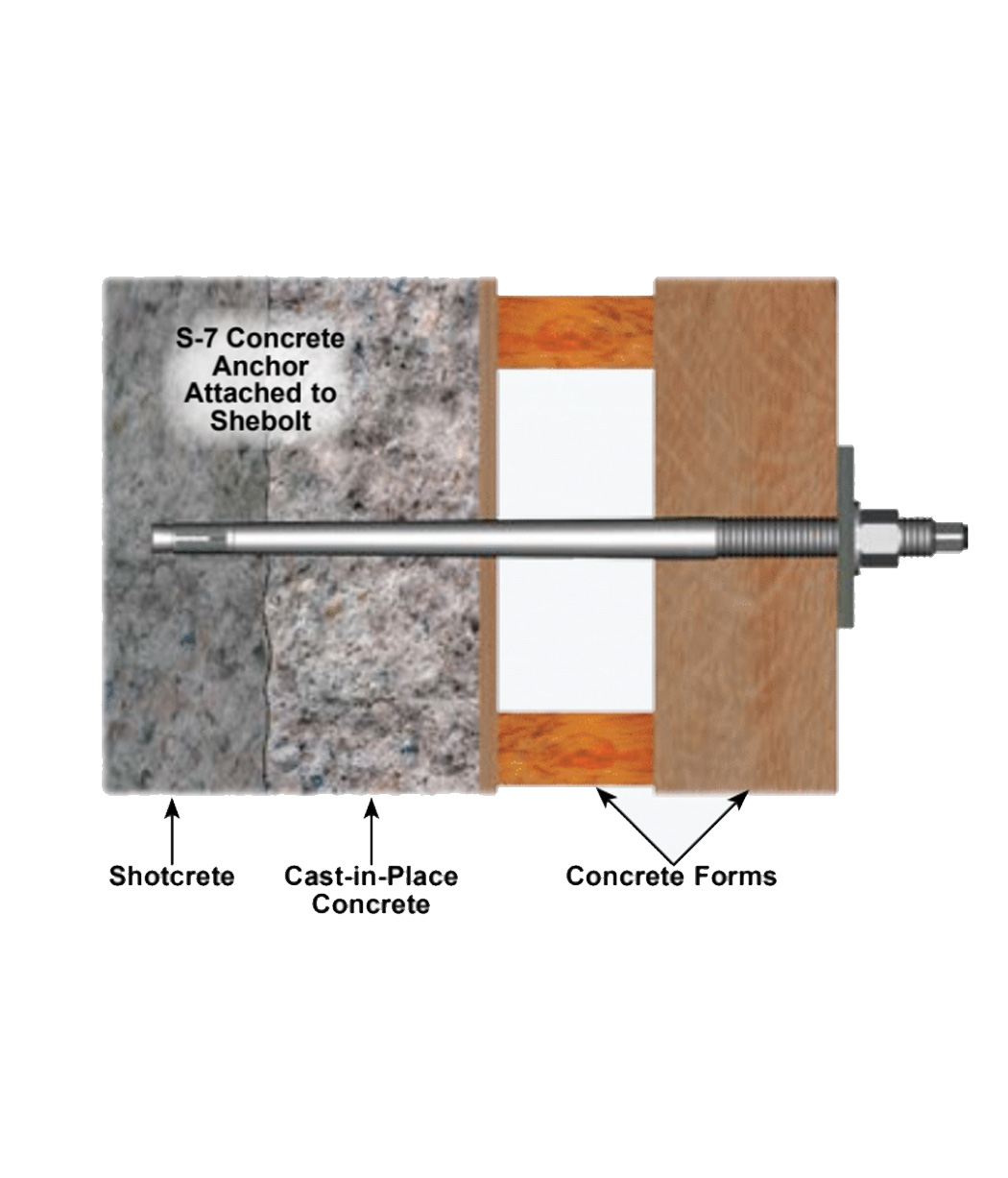

S-7 Concrete Form Tie